Bulkhead gate with high-precision flow control

A flow control and slab gate technology, applied in water conservancy projects, marine engineering, coastline protection, etc., can solve the problems of increasing the difficulty of operation and management, limited control accuracy of hoists, and difficulty in accurately controlling flow, so as to improve the accuracy of flow control. , the effect of avoiding the vibration of the gate and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

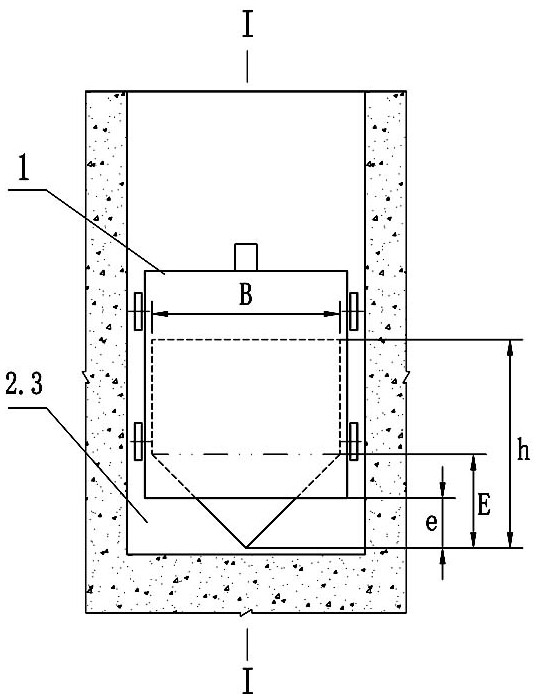

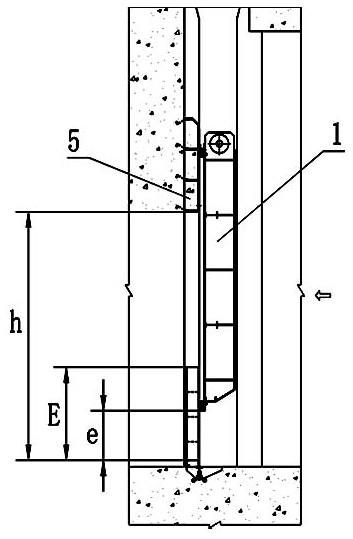

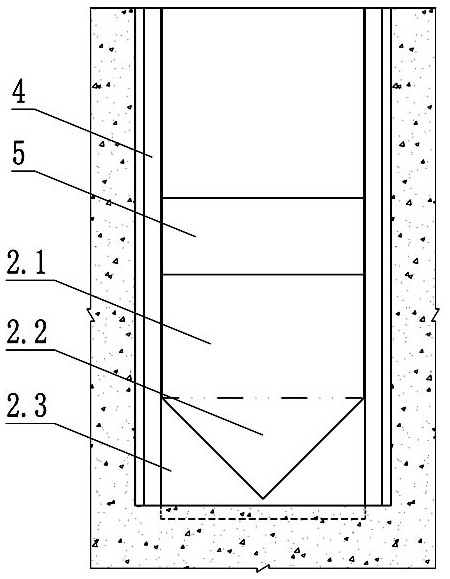

[0019] Such as Figure 1-7 As shown, the flat gate with high-precision flow control of the present invention includes a rectangular gate 1 driven to open / close by a hoist, a gate opening that is rolling and sealingly matched with the rectangular gate 1, and a pre-embedded gate opening. pieces.

[0020] Such as image 3 As shown, the shape of the gate opening is composed of an upper rectangular hole 2.1 and a lower V-shaped hole 2.2; a V-shaped bottom sill is pre-embedded in the reinforced concrete orifice 2.3 of the V-shaped hole 2.2.

[0021] Such as Figure 4

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap