Heat-retaining rolling equipment

A thermal device and heat preservation technology, which is applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of heat preservation effect limitation, heat preservation device is not easy to change the heat preservation cover, etc., so as to improve the heat preservation effect, Ease of maintenance operation and prevention of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

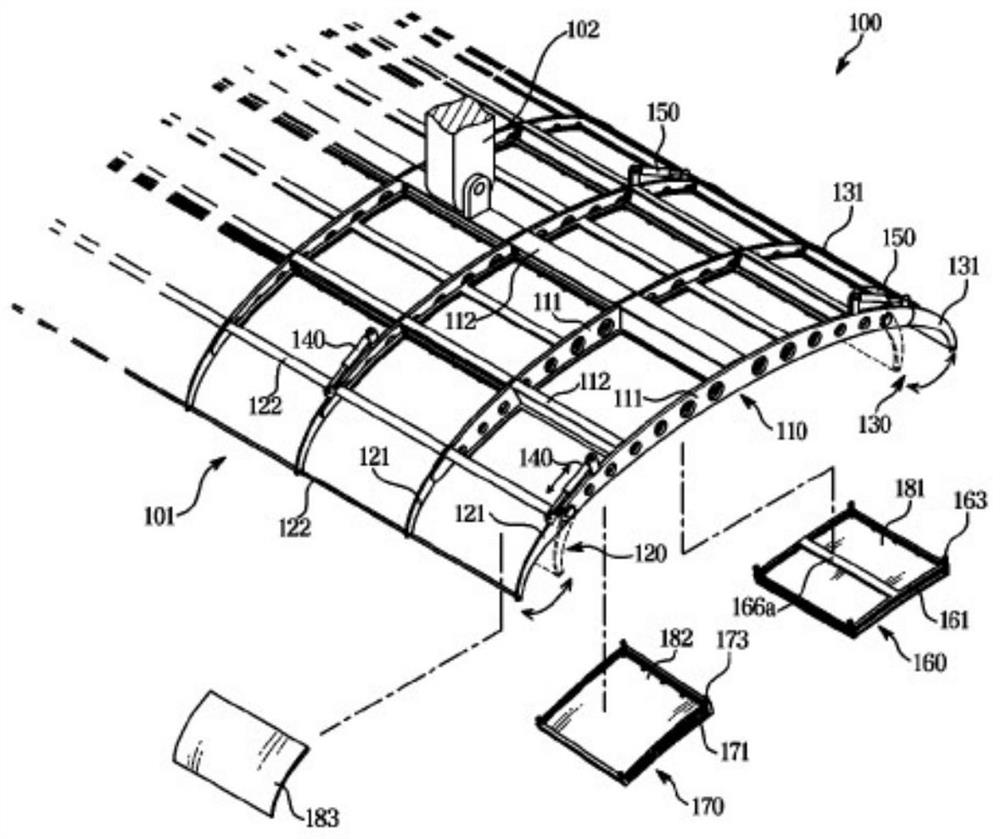

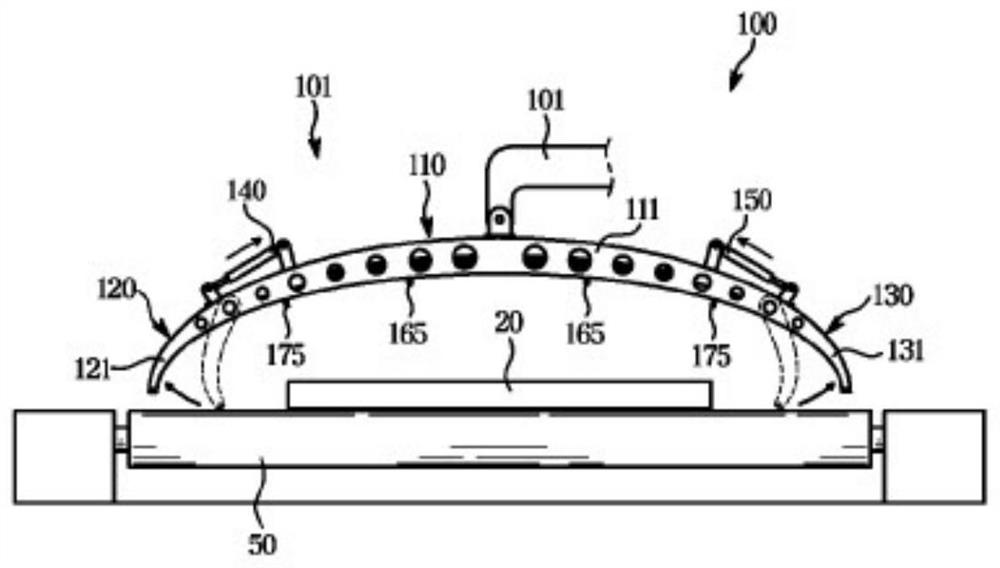

[0038] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings. The following examples are proposed to fully convey the idea of the present invention to those skilled in the art to which the present invention pertains. However, the present invention is not limited to the examples shown here, and may be embodied in other forms. In order to clarify the present invention, parts irrelevant to the description may be omitted in the figures, and the size of components may be appropriately enlarged to facilitate understanding.

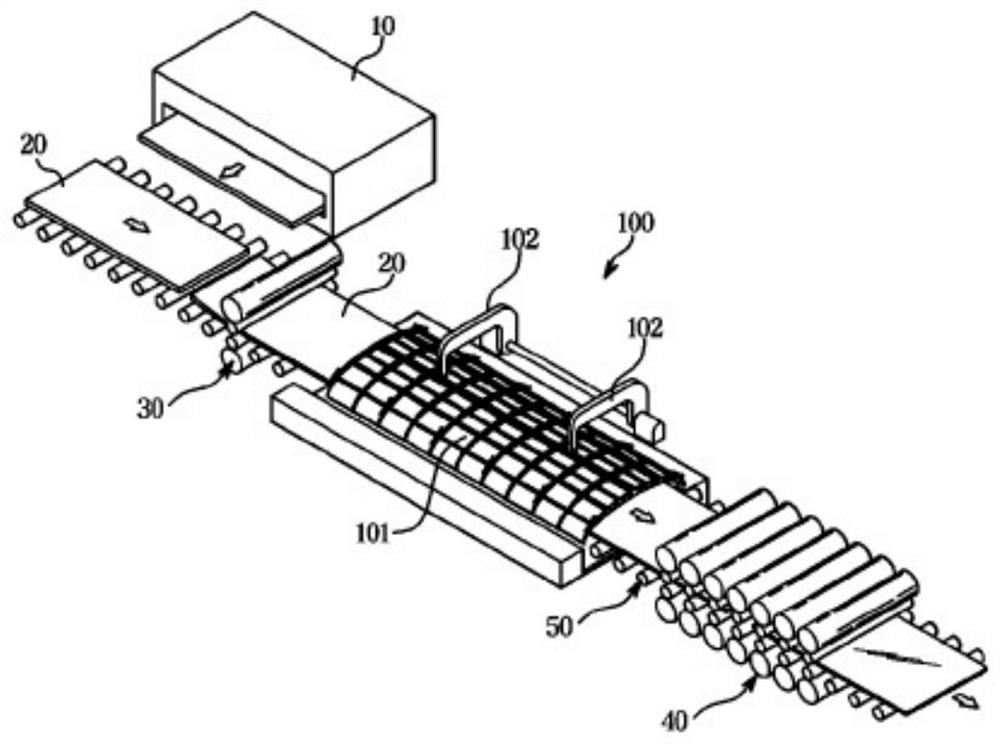

[0039] figure 1 is a perspective view showing a rolling device to which a heat retaining device according to an embodiment of the present invention is applied. refer to figure 1 , the rolling device comprises: a heating furnace 10, which heats the material for rolling; a rough rolling mill 30, which rolls the material 20 heated in the heating furnace 10; a finish rolling mill 40, which rolls...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap