Method for stabilizing COD operation of CSTR anaerobic reactor by using nickel

A technology of anaerobic reactor and measurement method, which is applied in the field of COD operation of CSTR anaerobic reactor using nickel to stabilize, can solve the problems of unstable effect, high price, poor universality, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

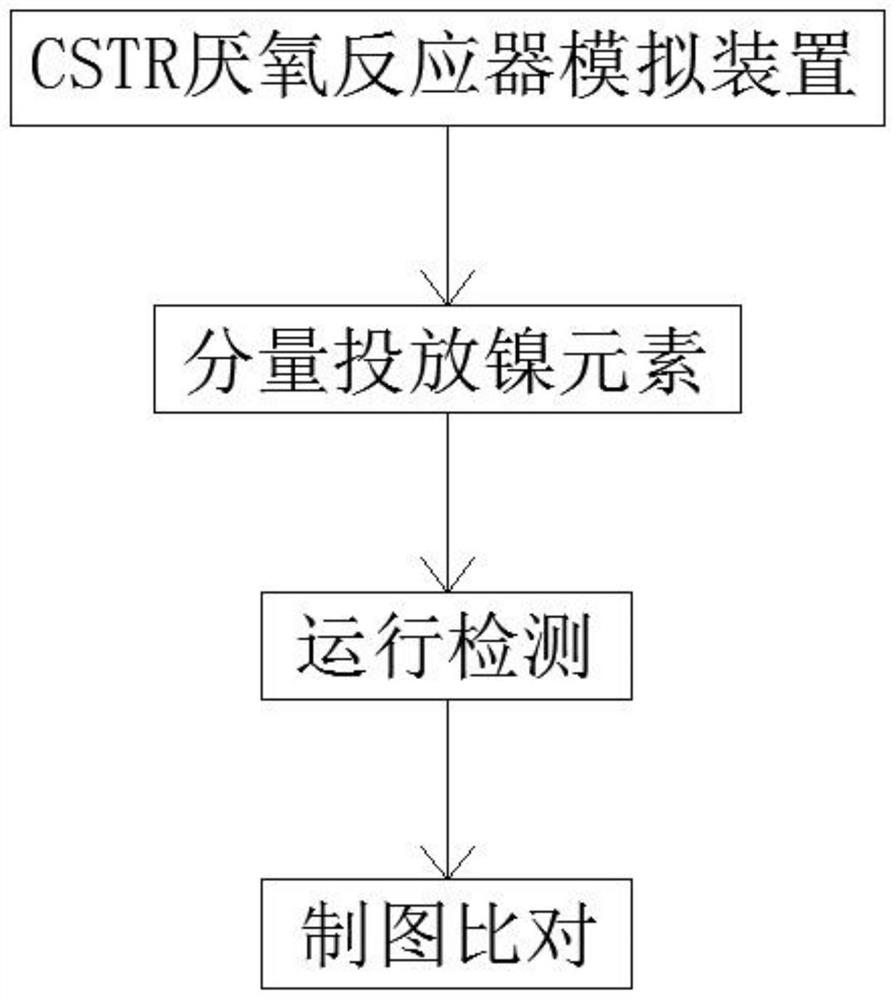

Method used

Image

Examples

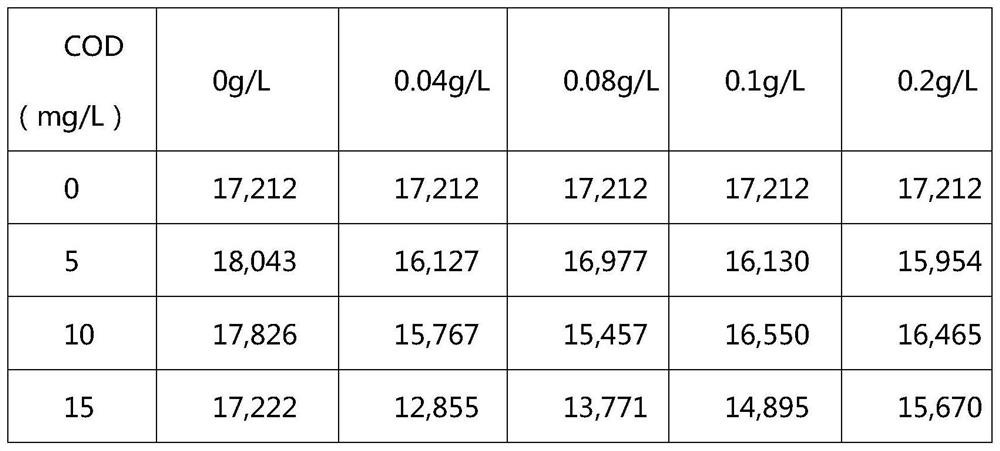

Embodiment 1

[0046] Practical example 1: Add hexahydrate nickel chloride to the CSTR anaerobic reactor in actual operation at a ratio of 0.04g / L at one time, observe the change of solvent load of COD, and do not stop feeding at the same time, keep the system running stably, specific implementation Data results (see image 3 ), COD rises to 15000mg / L under abnormal circumstances, after a single dose of 0.04g / L hexahydrate nickel chloride, within 5-10 days, the COD drops to the ideal state of 12000-13000mg / L, and maintains;

[0047] The method for utilizing nickel to stabilize the COD operation of the CSTR anaerobic reactor is to input hexahydrate nickel chloride into the CSTR anaerobic reactor at a rate of 0.04g / L at one time, and the COD can rise to 15000mg / L without stopping the feeding In the case of L, COD can be reduced to an ideal condition of 12000-13000mg / L within 5-10 days, which is conducive to stabilizing the COD value and maintaining the work quality, and nickel chlor

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap