Efficient cutting and seed taking equipment for trichosanthes kirilowii maxim fruit

A high-efficiency technology for Trichosanthes, applied in the field of high-efficiency cutting and seeding equipment for Trichosanthes fruit, can solve the problems of manpower consumption and low efficiency, and achieve the effects of stable operation, high efficiency and high cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

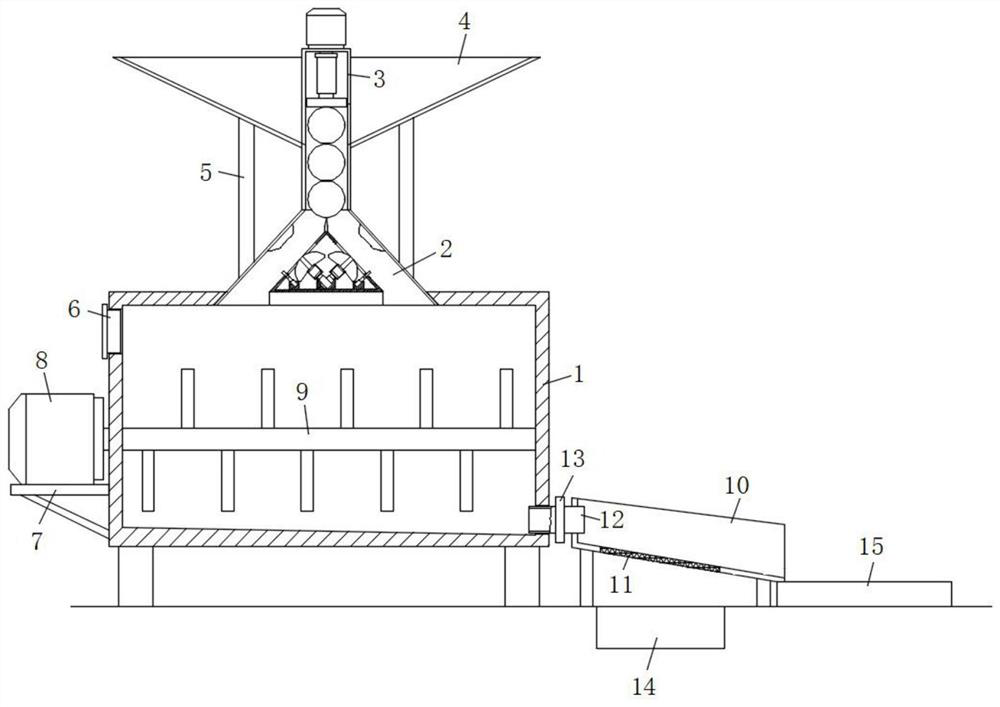

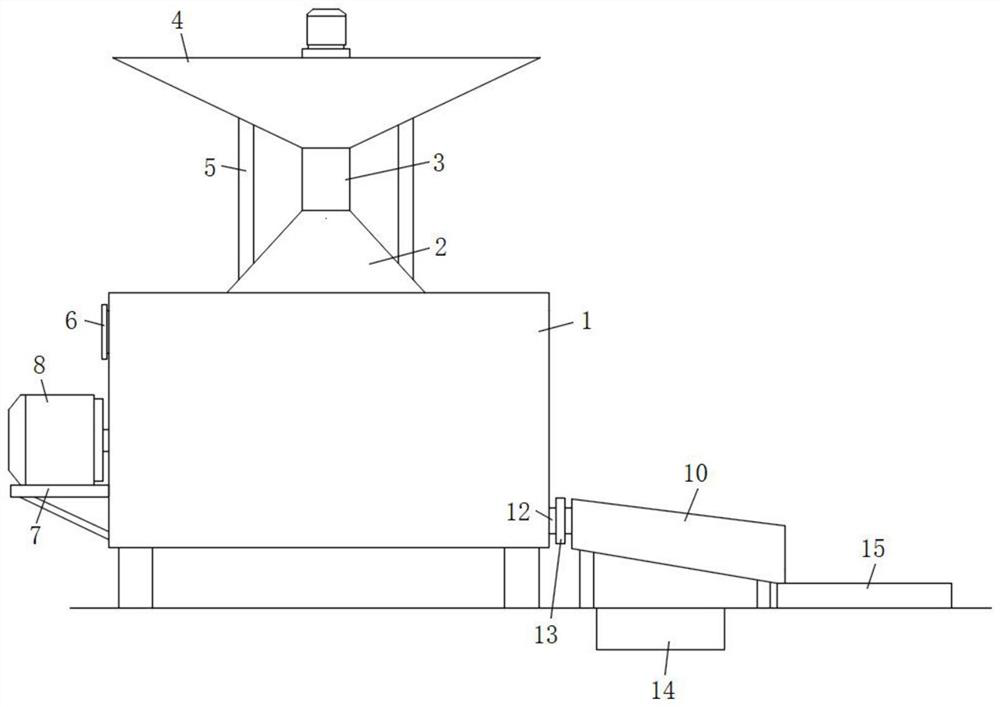

[0030] refer to Figure 1-5, a kind of high-efficiency cutting and seeding equipment for trichosanthes, comprising a sorting box 1, a seed picking mechanism 2 is fixed in the middle of the top side of the sorting box 1, and the seed picking mechanism 2 includes a conical dish 201 and a hollow cone 202, and the hollow cone 202 is fixed at the center of the top surface of the sorting box 1, and the conical dish 201 is connected through the top surface of the sorting box 1. The center of the inner bottom surface of the hollow cone 202 is welded with a fixed seat 203, and the top surface of the fixed seat 203 is There is a cylindrical groove 1, and the inner wall of the cylindrical groove 1 is fixed with an electric telescopic rod 1 204, and the output end of the electric telescopic rod 1 204 is fixed with a mounting cylinder 205 through screws, and the inner wall of the mounting cylinder 205 is fixed with a servo motor 1 206 through screws, The output end of the servo motor 1 206 is

Embodiment 2

[0032] like figure 1 , 2 As shown in and 5, this embodiment is basically the same as Embodiment 1. Preferably, the cutting mechanism 3 includes a lower material bucket 301, the bottom of the lower material bucket 301 is connected through the top of the conical dish 201, and the top surface of the lower material bucket 301 passes through The screw is fixedly connected with a servo motor 302, and the output end of the servo motor 302 passes through the top surface of the lower material barrel 301 and is fixed with a threaded cylinder 303. In block 305, a feeding port 306 is provided on one side of the feeding barrel 301 .

[0033] The feeding hopper 4 is sleeved and fixed on the outer wall of the lower material barrel 301 , and the feeding port 306 is arranged on the inner side of the lower end of the feeding hopper 4 , and the pressing block 305 is connected to the inner wall of the lower material barrel 301 in sliding contact.

[0034] In this embodiment, when in use, the threa

Embodiment 3

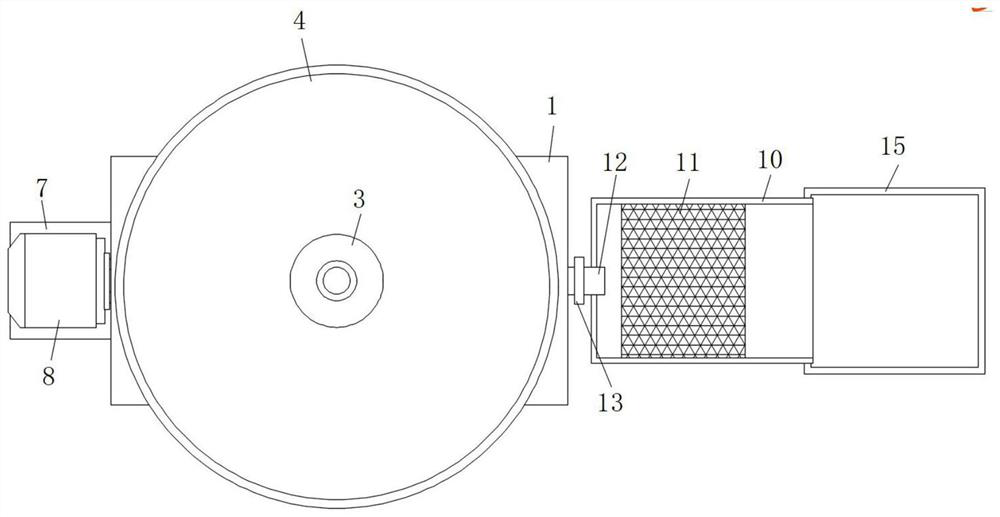

[0036] like Figure 4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, two cylindrical grooves are provided and distributed in a staggered manner on the front and back sides of the top of the fixed seat 203, and the two cylindrical grooves are respectively arranged on both sides of the hollow cone 202. .

[0037] In this embodiment, the front and rear sides of the top of the fixed seat 1 203 are provided with a cylindrical groove 1, so as to facilitate the simultaneous seeding operation of the Trichosanthes fruits on both sides, and then greatly improve the quality of cutting and seeding the Trichosanthes fruits.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap