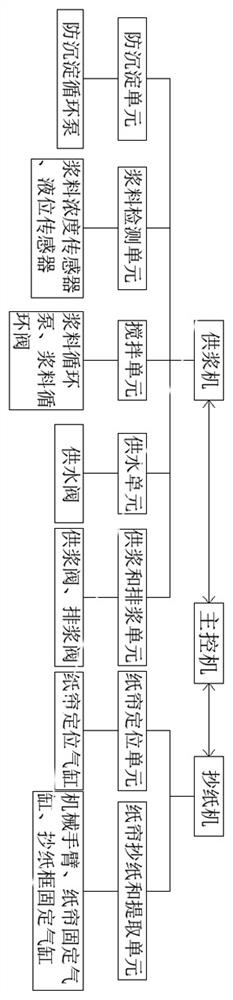

Automatic control system for automatically fishing original paper and control method thereof

An automatic control system and Yuanshu paper technology, applied in papermaking, paper machines, textiles and papermaking, etc., can solve the problems of reducing work efficiency and increasing labor intensity of workers, and achieve the effect of reducing labor intensity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

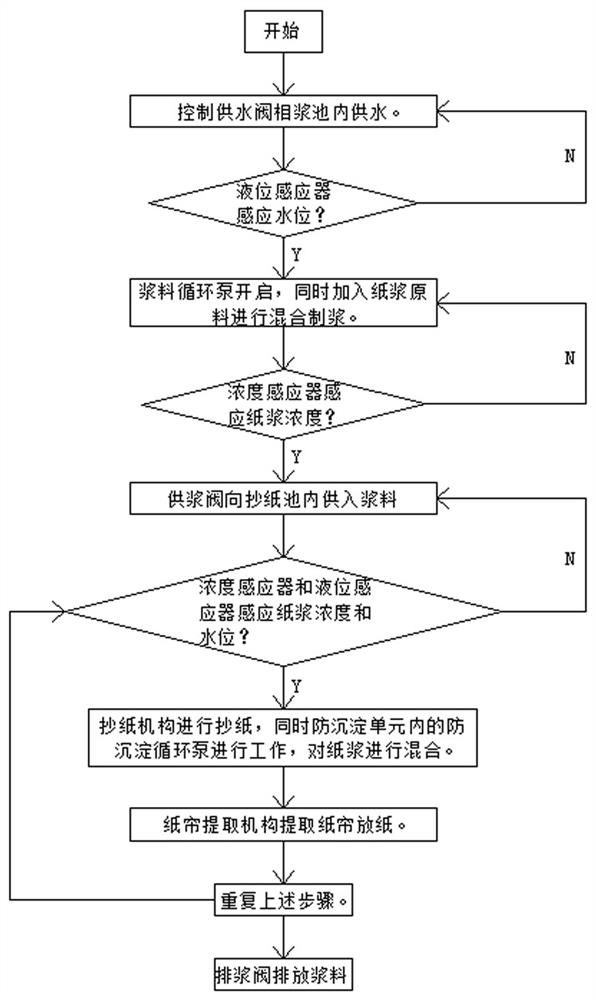

[0029] Example 1

[0030] The first step: the water supply valve on the water supply unit on the tap machine is opened by the main controller;

[0031] Step 2: The liquid level sensor within the slurry detection unit detects the water level in the slurry tank and transmits the measured water level data signal;

[0032] Step 3: When the water level data signal reaches a standard, put the pulp raw material into the slurry tank, and the main control machine controls the slurry cycle valve on the agitation unit to operate, and the slurry cycle is carried out, and the water and pulp feed materials are mixed for pulping. ;

[0033] Step 4: The slurry concentration sensor in the slurry detection unit is then detected on the pulp concentration in the slurry tank while transmitting the data signal obtained to the main control;

[0034] Step 5: When the detected concentration reaches the requirements, the main control machine controls the pulp and the molbage valve on the slurry unit, so that

Example Embodiment

[0039] Example 2

[0040] In this embodiment, the corresponding medium-turn pool is not provided in this embodiment. The main controller controls the pulping valve opens, the pulp is directly delivered to the anti-sedimentation area, and the anti-precipitation unit of the anti-precipitation unit is controlled by the main control. The pump works the pulp to continuously stir the dilution, and then flows to the paper-cutting pool, the object of this embodiment is the same as in Example 1.

Example Embodiment

[0041] Example 3

[0042] In this embodiment, the anti-precipitation region is not provided in this embodiment. The main controller controls the pulp valve opens, conveys the pulp to the middle transfer pool, and then dilute from the middle transfer, then flow to the paper sheet In the pool, the purpose achieved by this embodiment is the same as in Example 1-2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap