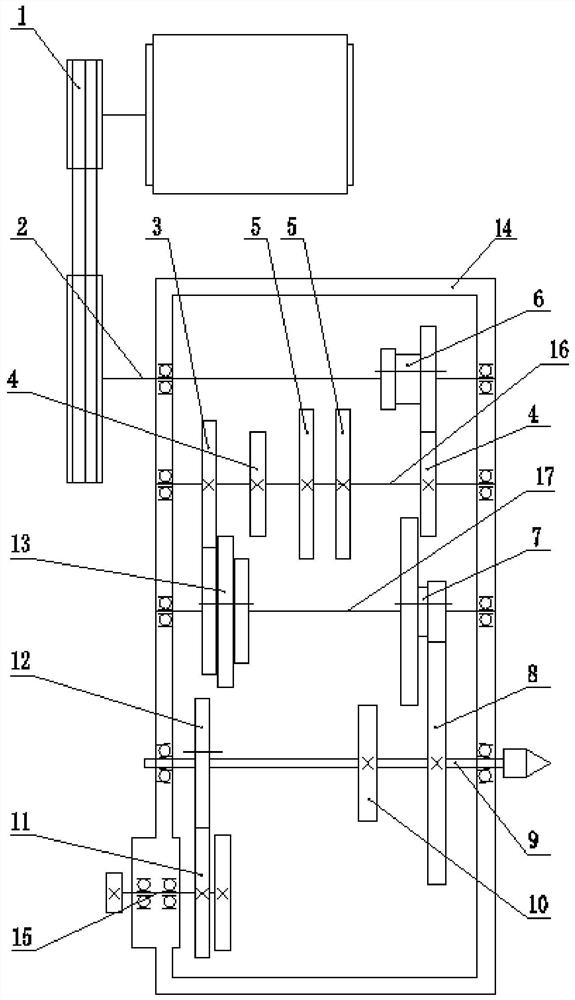

Twelve-speed-gear lathe spindle box assembly

A lathe spindle and assembly technology, applied in the direction of large fixed members, metal processing machinery parts, driving devices, etc., can solve the problems of high cost, cumbersome operation, large installation space, etc., and achieve low manufacturing cost, exquisite design, and practicality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

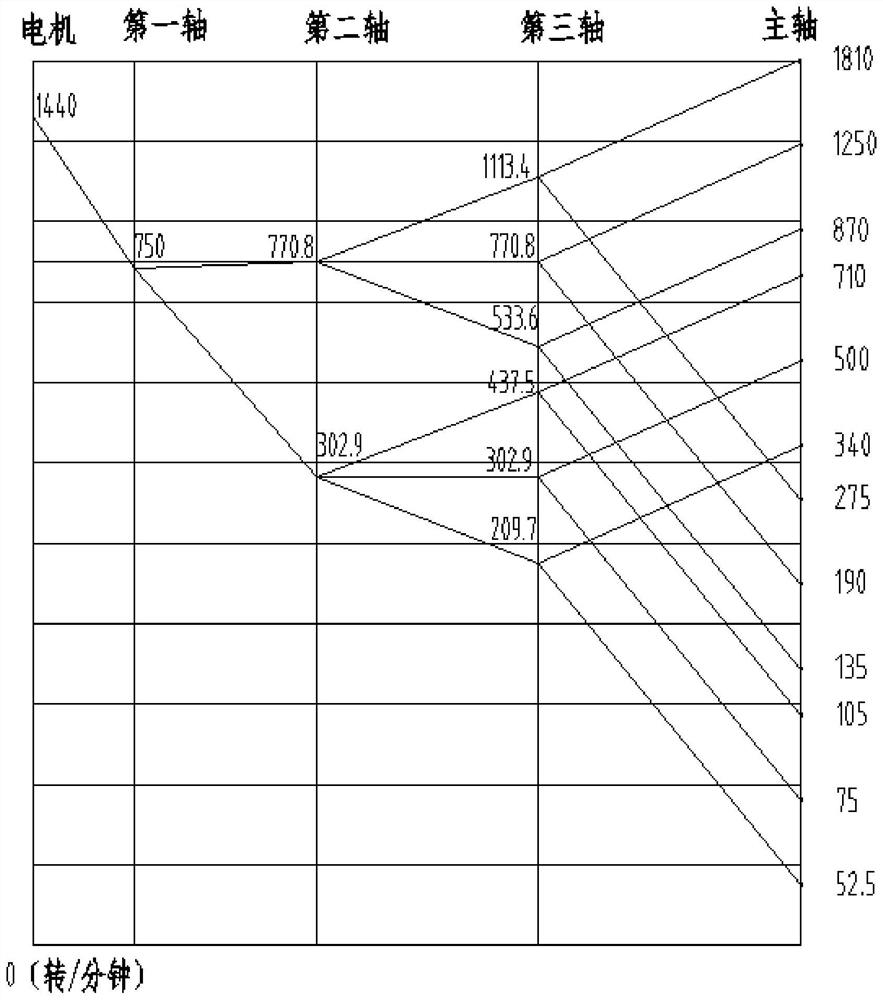

[0021] The transmission ratio reference setting of each gear is:

[0022] The diameter ratio of the two gears of the first-stage duplex sliding gear 6 is 21:37, and the gear with the smaller diameter is connected with the second-stage universal transmission gear A4, and the transmission ratio of the two is 21:36; the gear with the larger diameter The gear is in transmission connection with the secondary universal transmission gear B5, and the transmission ratio of the two is 37:52.

[0023] The transmission ratio of the secondary special transmission gear 3, the secondary general transmission gear A4 and the secondary general transmission gear B5 is 44:36:52, and the diameter ratio of the three gears of the secondary triple sliding gear 13 is 44:52: 36; the secondary universal transmission gear B5 is connected to the smallest gear transmission of the secondary triple sliding gear 13, and the transmission ratio of the two is 52:36; the secondary general transmission gear A4 is con

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap