Preparation of nanoscale vermiculite dispersion liquid and application of nanoscale vermiculite dispersion liquid in foam extinguishing agent

A dispersion liquid and nano-scale technology, which is applied in the direction of fire prevention equipment, etc., can solve the problems of stability and environmental pollution, etc., and achieve the effect of enhancing foam toughness, simple preparation method, and enhancing barrier isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Vermiculite modification: Add 200g of deionized water into a three-necked flask, then add 50g of expanded vermiculite into the bottle, and add 36.5g of modifier dodecyltrimethylammonium bromide. The reaction was carried out at a constant temperature of 80° C. for 6 hours. The obtained intercalated modified vermiculite was repeatedly washed with deionized water to remove excess modifier, and AgNO 3 The filtrate was detected to be free of bromide ions. Dry and weigh to obtain 44g of modified vermiculite.

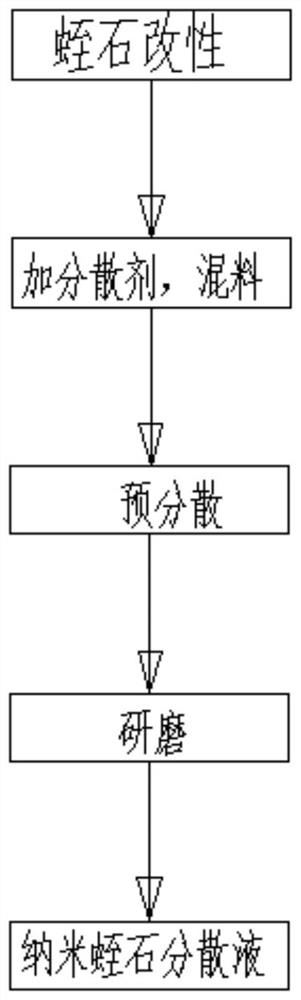

[0034] Vermiculite dispersion preparation: add the above-mentioned modified vermiculite of 5wt% (parts by weight) in a beaker, then gradually add 3wt% dispersant (modified acrylic anionic surfactant PL20, from Clariant), 2wt% Wetting agent (modified acrylate nonionic surfactant LCN407, from Clariant), and the rest added deionized water. It was pre-dispersed at 3000 rpm for 30 minutes under a high-speed stirrer, and the measured particle size was D50=39.5um. Transfer to

Embodiment 2

[0043] Vermiculite modification: Add 400g of deionized water into a three-necked flask, then add 100g of expanded vermiculite into the bottle, and add 103g of modifier cetyltrimethylammonium chloride. The reaction was carried out at a constant temperature of 80° C. for 6 hours. The obtained intercalated modified vermiculite was repeatedly washed with deionized water to remove excess modifier, and AgNO 3 Check the filtrate for the presence of chloride ions. Dry, weigh to obtain modified vermiculite dry product 102g.

[0044] Vermiculite dispersion preparation: add the above-mentioned modified vermiculite of 10wt% (parts by weight) in a beaker, then gradually add 5wt% dispersant (sodium lauryl sulfate, from Shanghai Sinopharm Group), 1wt% moistening agent Wetting agent (modified acrylate non-ionic surfactant LCN407, from Clariant), and the rest added deionized water. It was pre-dispersed at 2500 rpm for 60 minutes under a high-speed stirrer, and the measured particle size was D5

Embodiment 3

[0050] A kind of preparation of nanoscale vermiculite dispersion liquid, it is the following steps: (1) vermiculite modification, vermiculite obtains intercalation modified vermiculite through quaternary ammonium salt cation exchange modification; (2) modified vermiculite grinding , adding a dispersant and sanding in a sand mill to obtain a nano-vermiculite dispersion with an average particle size of 100 nanometers.

[0051] The vermiculite modification of the step (1), the vermiculite is obtained by intercalation modified vermiculite through quaternary ammonium salt cation exchange, and the reaction temperature is 60 ° C; the quaternary ammonium salt cation modifier is C12 alkyl trialkyl chloride ammonium chloride; after modification, the modified vermiculite is obtained by washing with water, filtering and drying.

[0052] The vermiculite is expandable vermiculite and expanded vermiculite, and its average particle size is 300 mesh.

[0053] The equipment used for grinding the

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap