Locking and separating disassembly and assembly structure of drawer panel

A lock-off and panel technology, which is applied to drawers, furniture parts, household appliances, etc., can solve the problems of complex mechanism, poor user experience, damage and high failure rate, and achieve the effect of simplifying the structure of disassembly and assembly and stabilizing disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0045] Example embodiments of the present invention will be further described in conjunction with the accompanying drawings and the following.

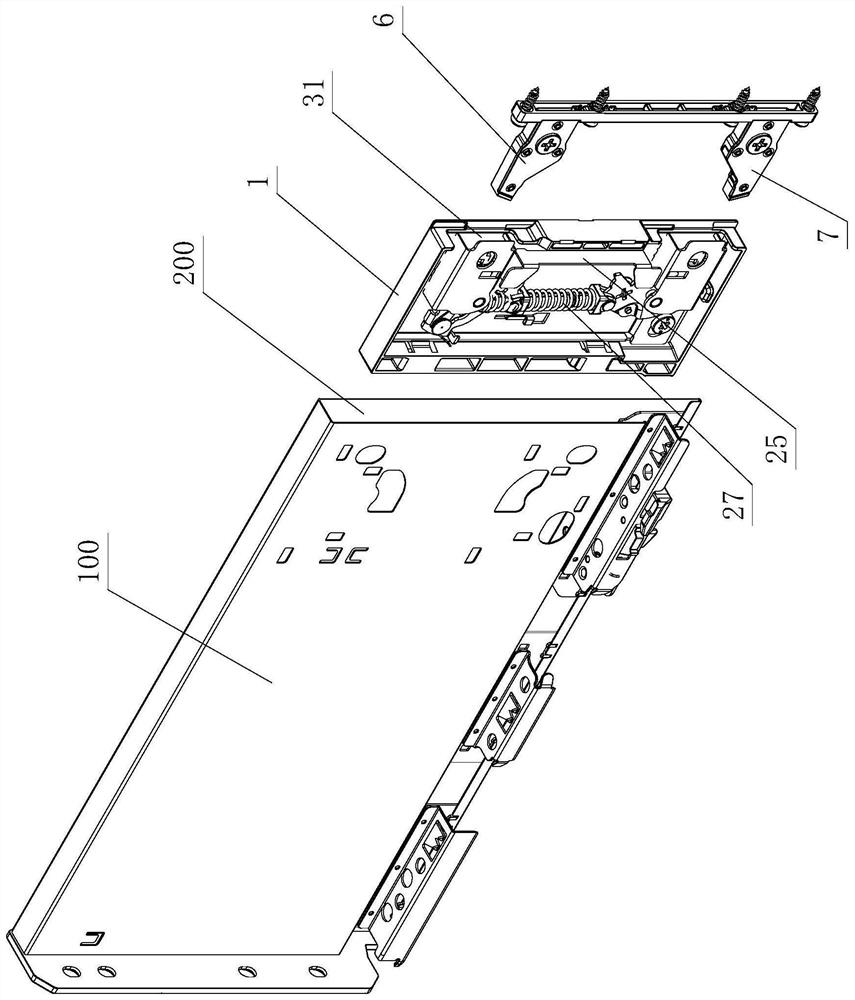

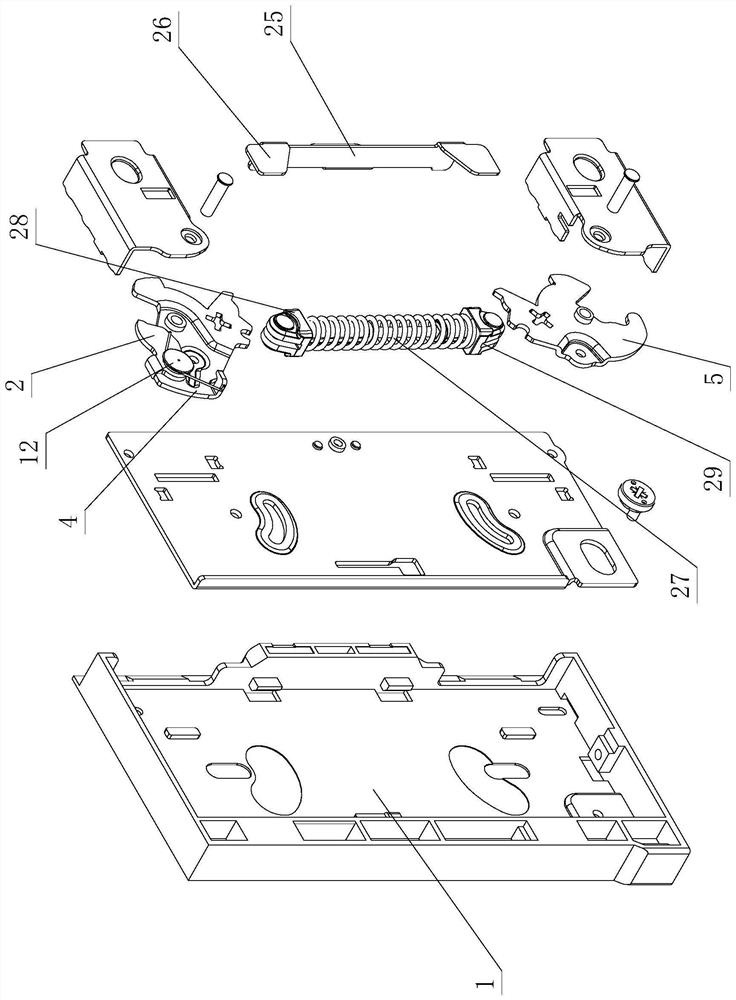

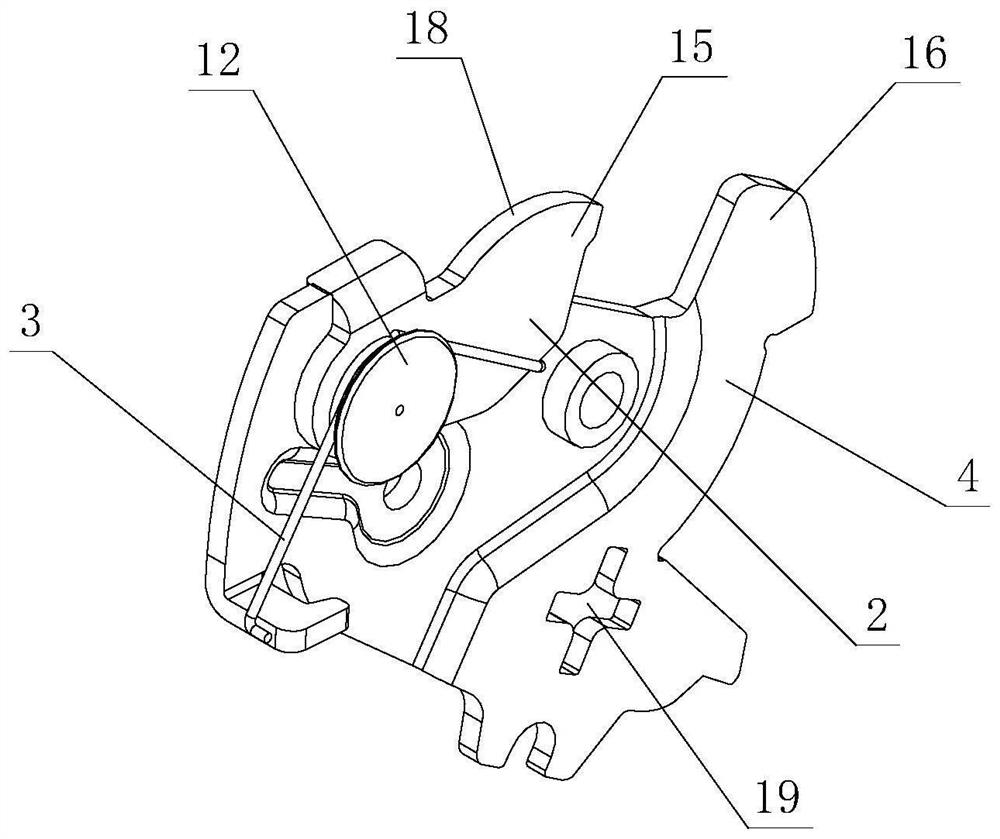

[0046] See Figure 1 - Figure 17 , Lock this removable from the drawer panel structure, comprising a side plate 100, the drawer panel, the connecting element and the fastening element 1, the connecting element provided with two or more, and are fixedly connected to the drawer panel; a front end of the side plate 100 It is provided with a fitting groove 200; the fixing member 1 is fixed on a mounting groove 200, and which is provided with two or more locks for locking the connector member and the separation member away; from more than two locking elements disposed relatively independent , and mutually provided between a common elastic components.

[0047] Are respectively connected with two or more locking elements and separation, in order to achieve the above two elements removably connecting two or more locks when the elastic member are elas

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap