Glass-lined container with magnetic stirring function

A magnetic stirring and magnetic stirring machine technology, which is applied in chemical instruments and methods, chemical/physical/physical chemical fixed reactors, mixers, etc., can solve the problems of glaze layer damage, shaking and loosening of stirring mechanisms, and prevent shaking , to avoid shaking, to avoid the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

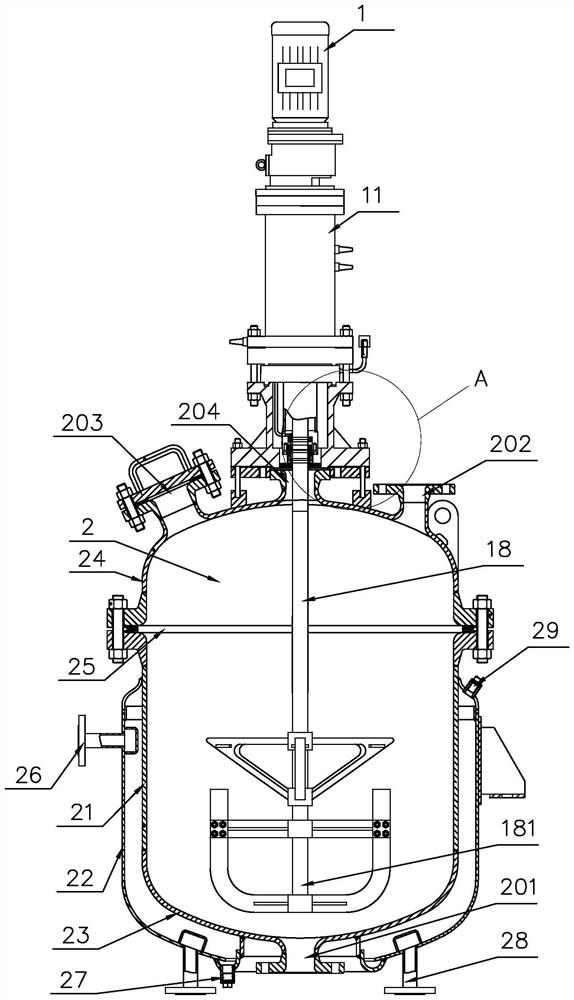

[0022] A glass-lined container with magnetic stirring, comprising a stirring mechanism 1 and a reaction tank 2, the inner side of the reaction tank 2 is provided with a stirring mechanism 1;

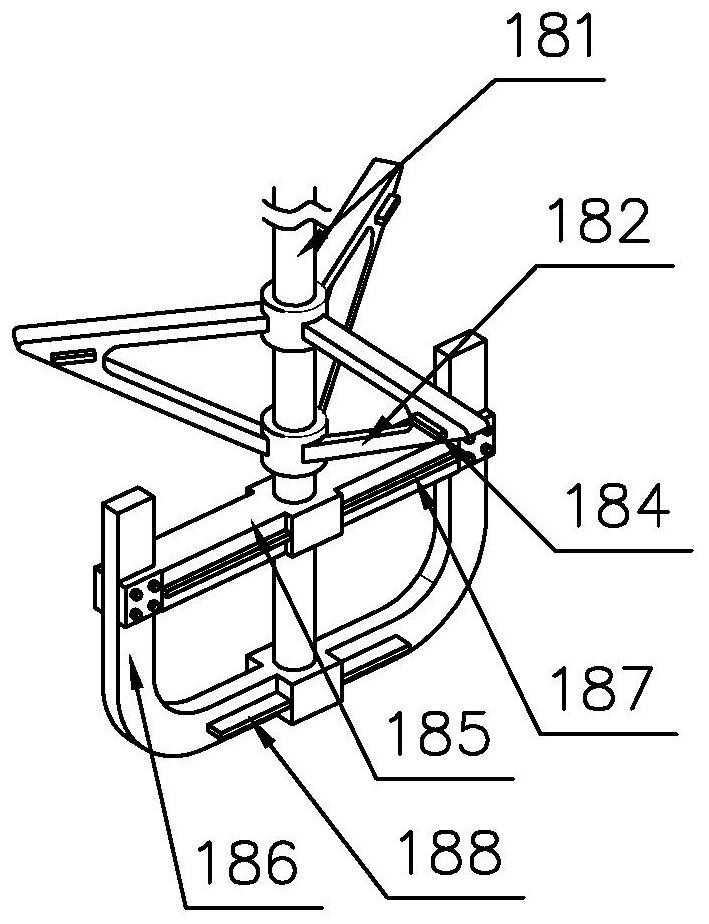

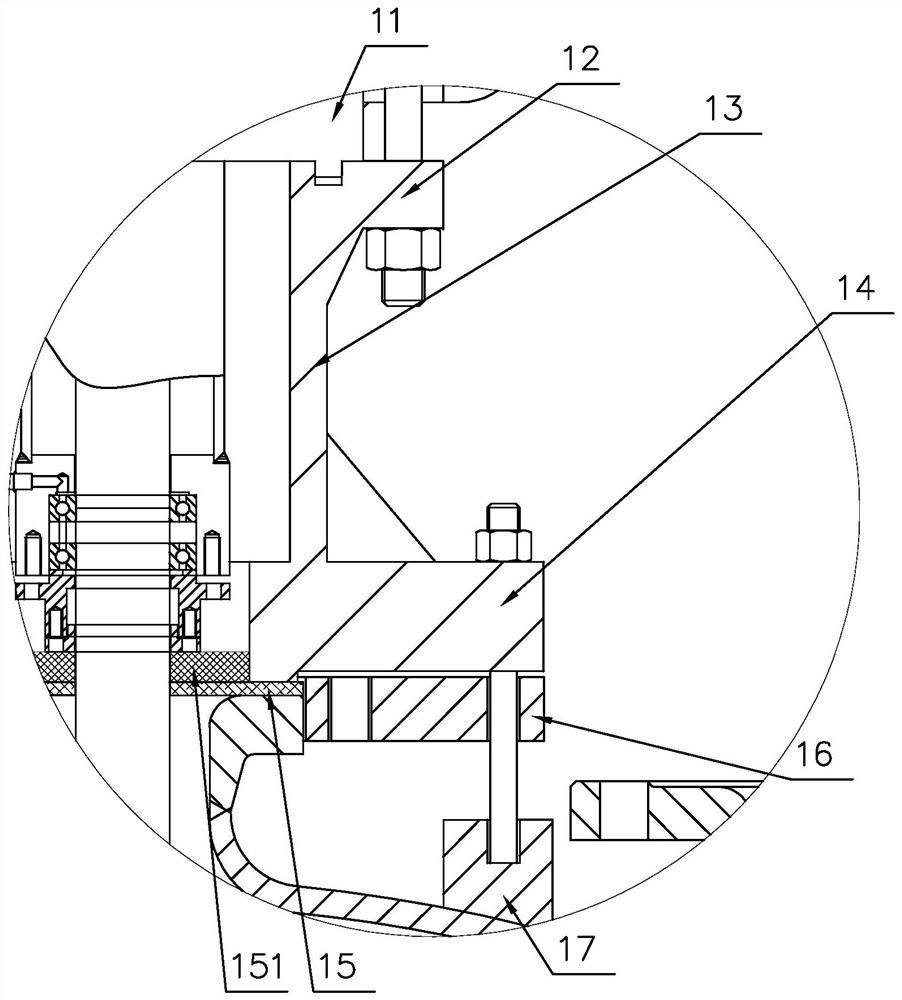

[0023] The stirring mechanism 1 includes a magnetic stirrer 11, a bearing ring 12, a support plate 13, a support seat 14, a cover plate 15, a gasket 151, a limit ring 16, a connecting block 17, and a stirring group 18. One side of the magnetic stirrer 11 A bearing ring 12 is provided, and a plurality of support plates 13 are provided on one side of the bearing ring 12, a support seat 14 is provided at the bottom of the support plate 13, a gasket 151 is provided on the inner side of the support seat 14, and a cover plate 15 is provided on one side of the support seat 14. A limit ring 16 is provided on the outside of the plate 15, and a connecting block 17 is provided on one side of the limit ring 16, and the stirring group 18 is connected with the magnetic stirrer 11;

[0024] The magnetic s

Embodiment 2

[0034] Compared with Example 1, the preparation process of a glass-lined container with magnetic stirring is as follows: the tank body 21, the lower head 23, and the billet of the discharge port 201 are welded to form, and then the tank cover 24 and the The stirring port 204, the hand hole 203 and the steel billets with reserved holes are welded and formed, and then the welded and formed steel billets are respectively heated and fired to eliminate internal stress, and the surface of the steel billets is polished, and the tank body 21, the lower head 23, The inner wall of the steel billet of the discharge port 201, the tank cover 24, the stirring port 204, the hand hole 203 and the inner wall of the reserved hole are sprayed with a bottom glaze and then fired, and then the top glaze is sprayed on the bottom glaze and fired again. The composition of the top glaze The ingredients include: silicon dioxide 68.7%, sodium oxide 15.9%, titanium dioxide 0.9%, diboron trioxide 4.7%, lithium

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap