Porous solid ionic gel electrode and preparation method and application thereof

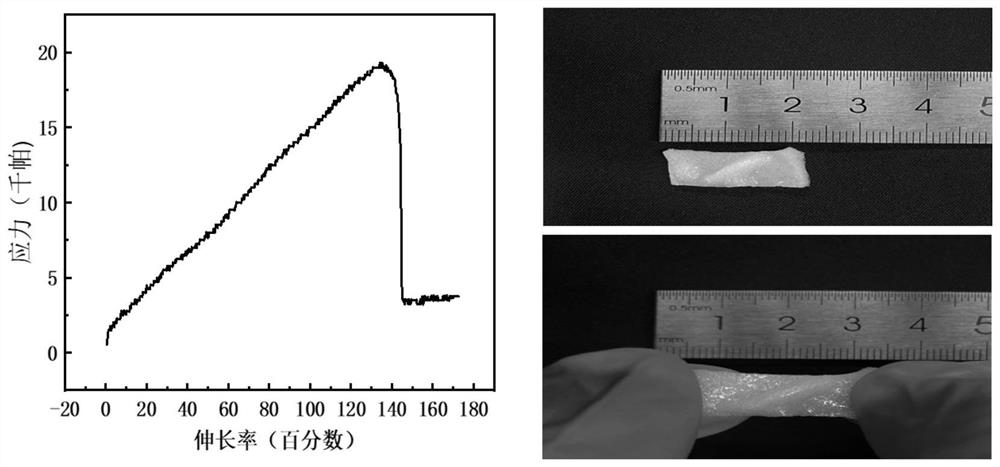

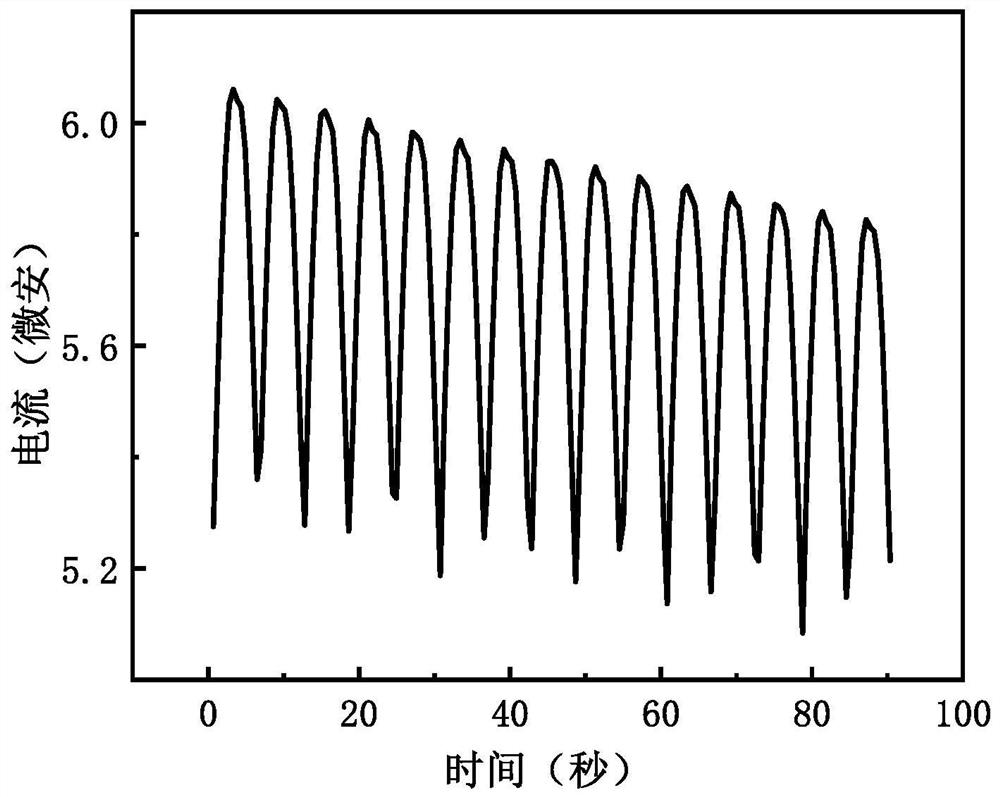

A technology of ion gels and solid ions, which is applied in the field of conductive ion gels and flexible devices, can solve the problems that are difficult to meet high flexibility and high sensitivity at the same time, and achieve the effect of good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] Example 1

[0028] (1) Weigh 9.1 g of double trifluoromethanesulfonyl amide and 7 ml of tetraned diol dimethyl ether in a glass bottle, and the sealing is stirred for 12 h to give a slightly viscous solvation ionic fluid.

[0029] (2) 3 ml of acrylate, 1 ml of ethoxyethoxyethyl escetyl ester, 2 ml of the above prepared solvate ionic fluid and 10 μl of polyethylene glycol diacrylate and 0.04 g of 1-hydroxycyclohexylphenyl group The ketone is added to the small glass bottle to stir, so that it is mixed uniform to obtain an ion gel precursor solution.

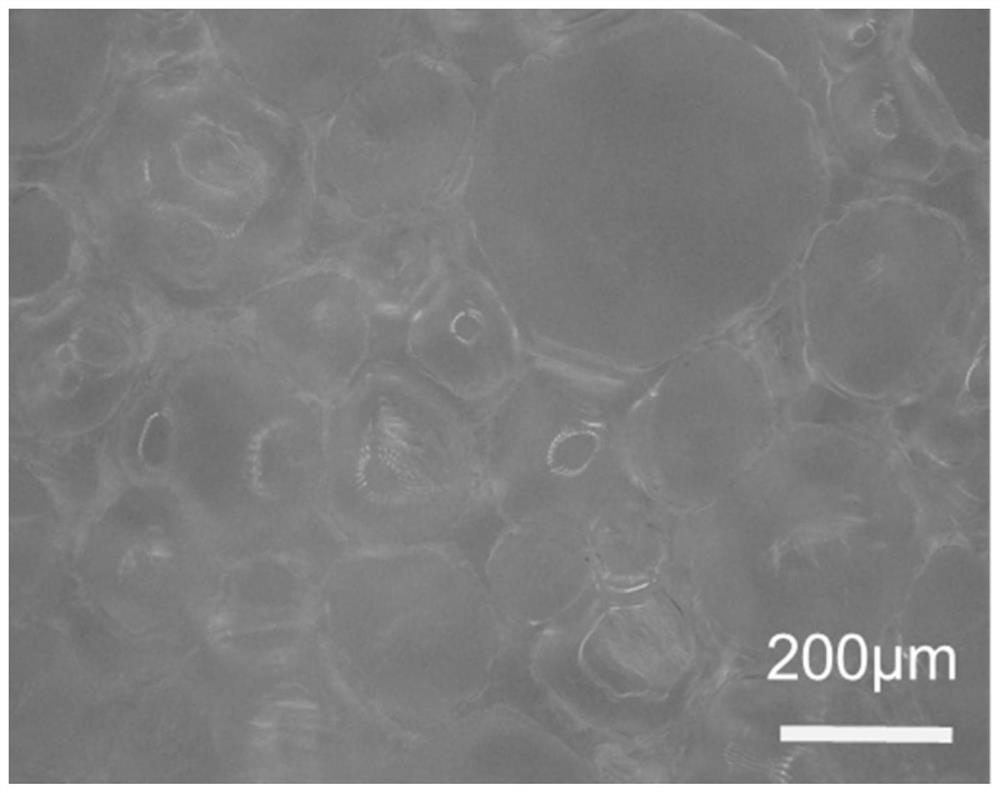

[0030] (3) Weighing 0.1 g of ammonium bicarbonate added to 2 mL of the above prepared ion gel precursor solution, stirred for 1 h, making it mixed uniform. Under the transparent mold of a pipette to a tracery film, then place the molded mold on the heater that has been preheated to 100 ° C, adjust the ultraviolet lamp to irradiate power, and select a gradient power irradiation mode. 10W was irradiated for 30 seconds, 5 W for 1 min

Example Embodiment

[0031] Example 2

[0032] (1) Weigh 5.2 g of double trifluoromethane sulfonylimide and 4 ml of tetranedethydrol dimethyl ether in a glass bottle, and the sealing is stirred for 12 h to give a slightly viscous solvate ionic fluid.

[0033] (2) 2.66 mL of propyl acrylate, 1.33 mL of ethoxyethoxyethyl escetyl escetyl ester, 2 ml of the prepared solvated ionic liquid and 10 μL of polyethylene glycol triacrylate and 1.25 g 1 - Hydroxy cyclohexylphenyl ketone is added to the small glass bottle to stir, so that it is mixed uniform to give an ion gel precursor solution.

[0034] (3) Weighing 0.1 g of ammonium bicarbonate added to 2 mL of the above prepared ion gel precursor solution, stirred for 1 h, making it mixed uniform. In the transparent mold of 1 ml to a tracery film with a pipette, the power of the ultraviolet lamp was 10 W under room temperature, and the solution was allowed to obtain a porous ion gel electrode after 2 minutes.

Example Embodiment

[0035] Example 3

[0036] (1) Weigh 6.5 g of double trifluoromethanesulfonazide dissolved in 5 ml of tetraned diol dimethyl ether, and the two chelate reactions, and release heat. After stirring at room temperature for 24 h, a solvated ionic liquid having a certain viscosity was obtained.

[0037] (2) 5 ml of hydroxyethyl acrylate, 5 ml of ethoxyethoxyethyl acrylate, 5 ml of the prepared solvated ionic liquid and 50 μl of polyethylene glycol diacrylate and 0.1 g 1-hydroxy cyclohexylphenyl group Methodophenone is added to a 20 ml small glass bottle in the sealing of the sealing, so that it is mixed to mix and give the ion gel precursor solution.

[0038] (3) Weighing 0.3 g of ammonium bicarbonate to 3 mL of the above prepared ion gel precursor solution, stirred for 1 h, so that it is mixed. Upper 1ml of 1ml into the transparent mold of the release film with a pipette, and then placed on a heating station with a solution to 100 ° C, adjusting the power of the ultraviolet lamp to 10W, a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap