Tube shell material of aluminum-based assembly suitable for laser seal welding, assembly shell and packaging process of assembly shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

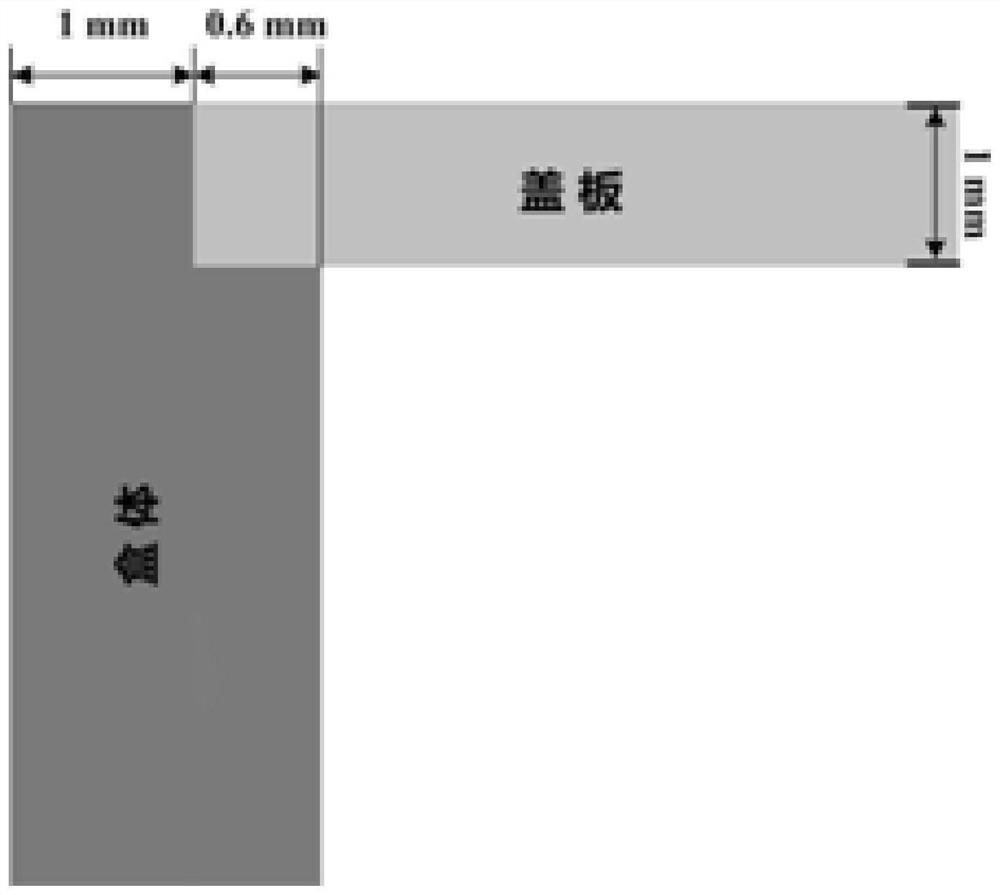

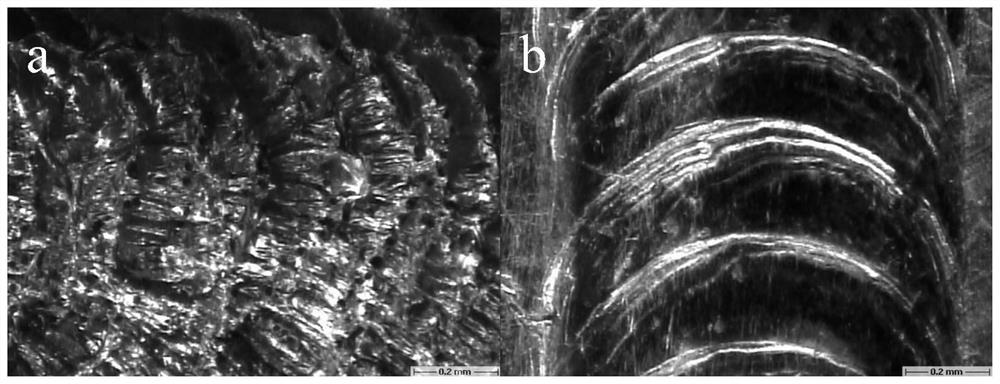

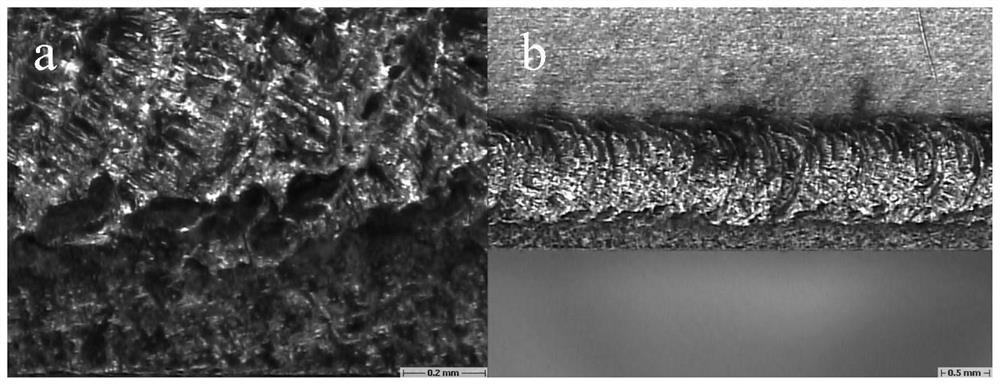

Image

Examples

Embodiment Construction

[0027] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0028] A shell material for aluminum-based components suitable for laser sealing and welding, comprising the following components: Fe: 0.2-0.5%, Si: 10-20%, Mg: 0.05-0.18%, Mn: 0.20-0.38%, Zn : 0.01-0.03%, the rest is Al and trace impurities.

[0029] 1. The effect of alloying elements on the properties of aluminum alloy:

[0030] 1. Silicon element

[0031] At the eutectic temperature of AlSi alloy system at 577°C, the maximum solubility of silicon in solid solution is 1.65%. The solubility decreases as the temperature decreases. Generally, such alloys cannot be strengthened by heat treatment. Aluminum-silicon alloys have excellent casting properties and corrosion resistance. If magnesium and silicon are added to aluminum at the same time to form an aluminum-magnesium-silicon alloy, the strengthening phas

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap