Diamond saw blade and laser welding preparation method thereof

A diamond saw blade and laser welding technology, which is applied in the field of powder metallurgy materials, can solve the problems of inability to effectively reduce cutting dust, inconvenience in recycling the substrate, and poor cooling effect of the knife edge, so as to solve the problem of poor cooling effect and reduce dust. The effect of producing and improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

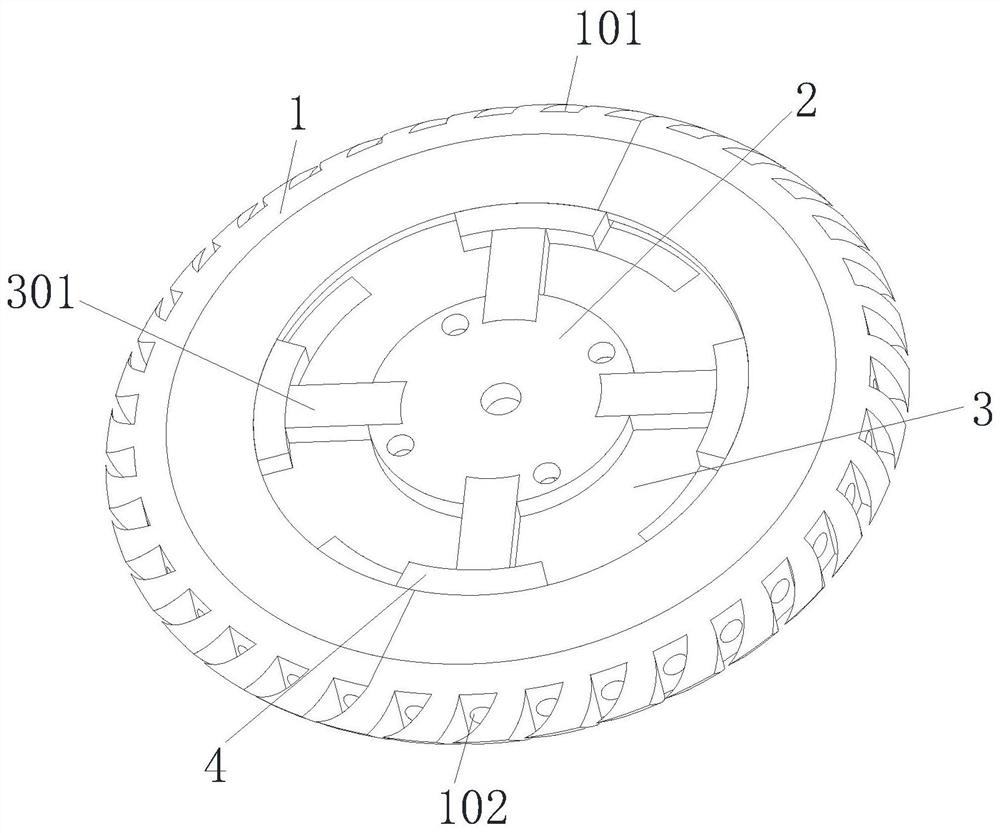

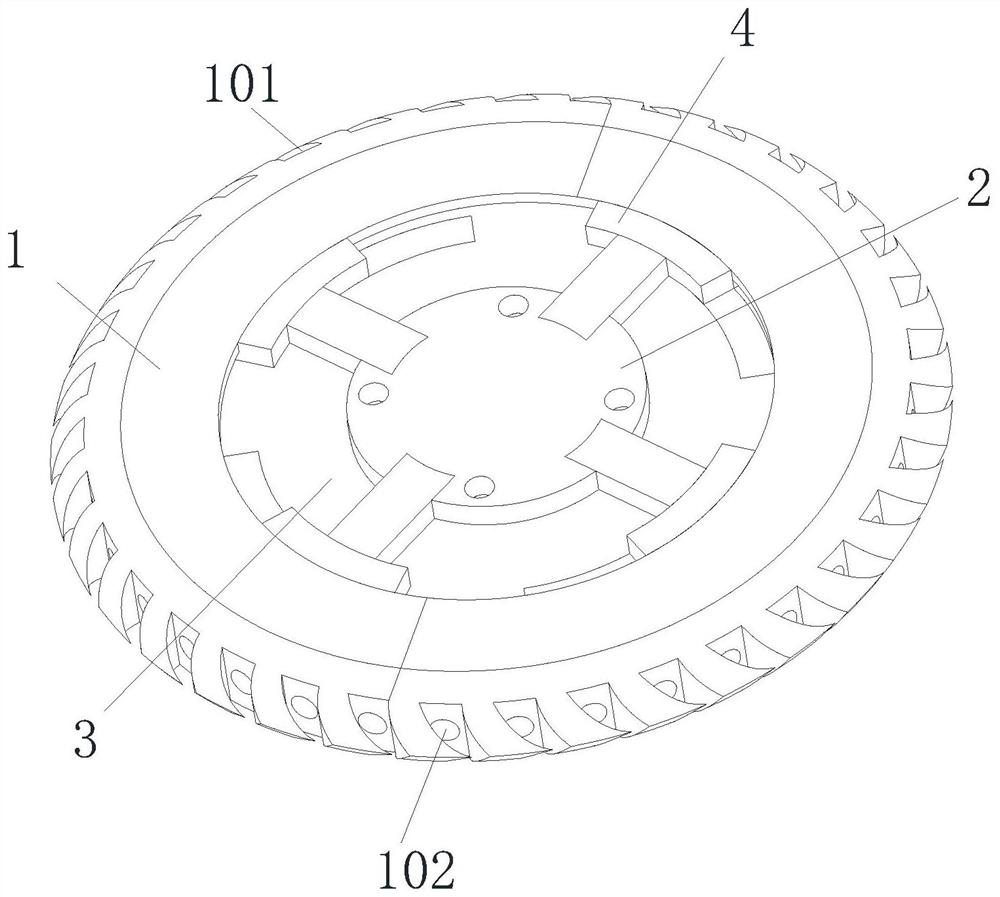

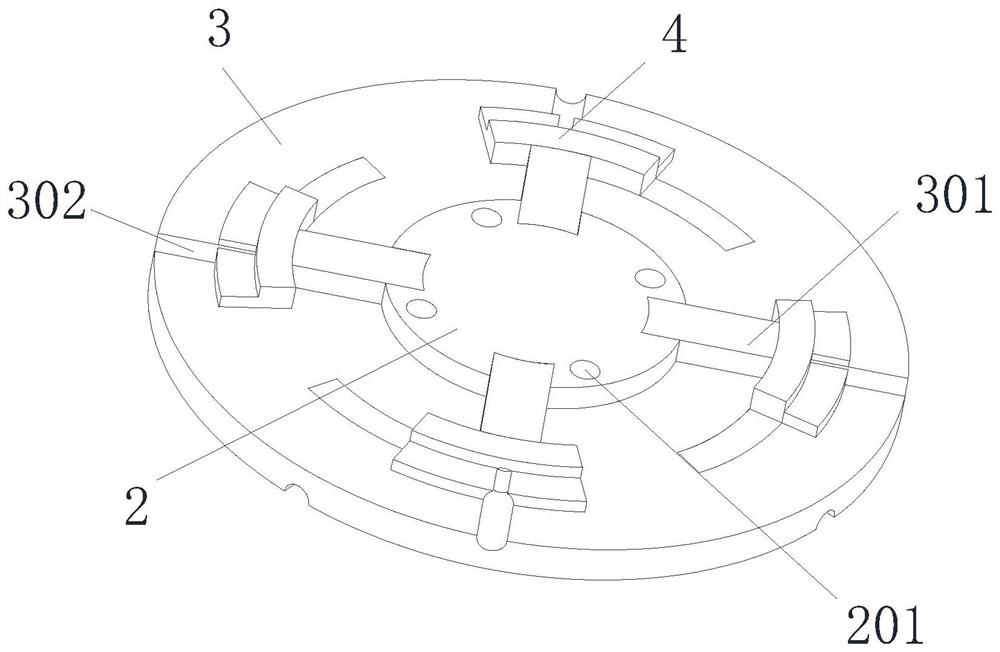

[0034] See Figure 1-7 The present invention provides the following technical solution: a diamond saw blade, including a saw blade base 3, a saw blade base 3, a saw blade base 3, and a saw blade base 3, a saw blade body 1, a saw The film body 1 has a higher hardness, and the midfunction of the saw blade base 3 is provided with the mounting assembly 2, and the arrangement of the mounting assembly 2 is provided to the cutting device. In, and to ensure that the saw blade base 3 does not receive a large wear during the cutting device, the mounting assembly 2 includes a top cover 202 and a lower cover 203, which is easy to install the diamond saw blade. 2 Assembled to the cutting device, the saw blade base 3 is fixed to the reinforcing rib 301, and the arrangement of the reinforcing rib 301 improves the structural strength of the saw blade base 3, and it is convenient for the setting of the guide groove 302, so that the cooling water can be smooth. The conveyance to the position of the saw

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap