Vacuum capacitor capable of changing capacitance

A vacuum capacitor and capacitor capacity technology, applied in the electronic field, can solve problems affecting the service life and use cost of vacuum capacitors, affecting the production efficiency of semiconductor chips, and inaccurate adjustment of capacitor value, so as to shorten the capacitor adjustment time and facilitate long-term stability The effect of fast use and adjustment speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

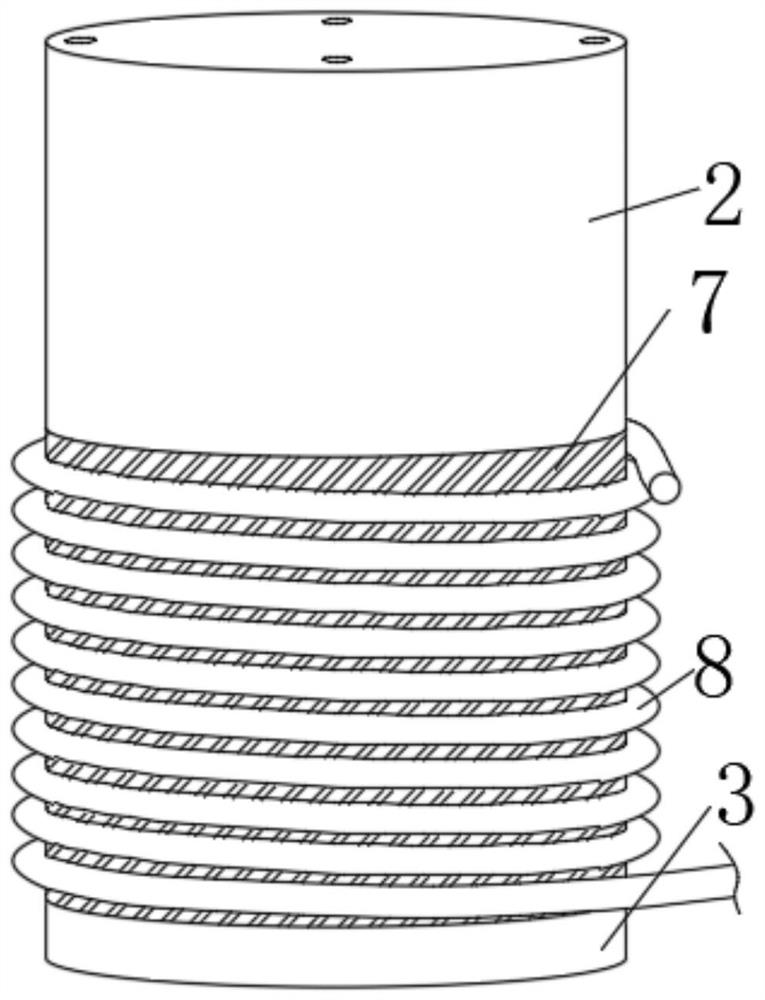

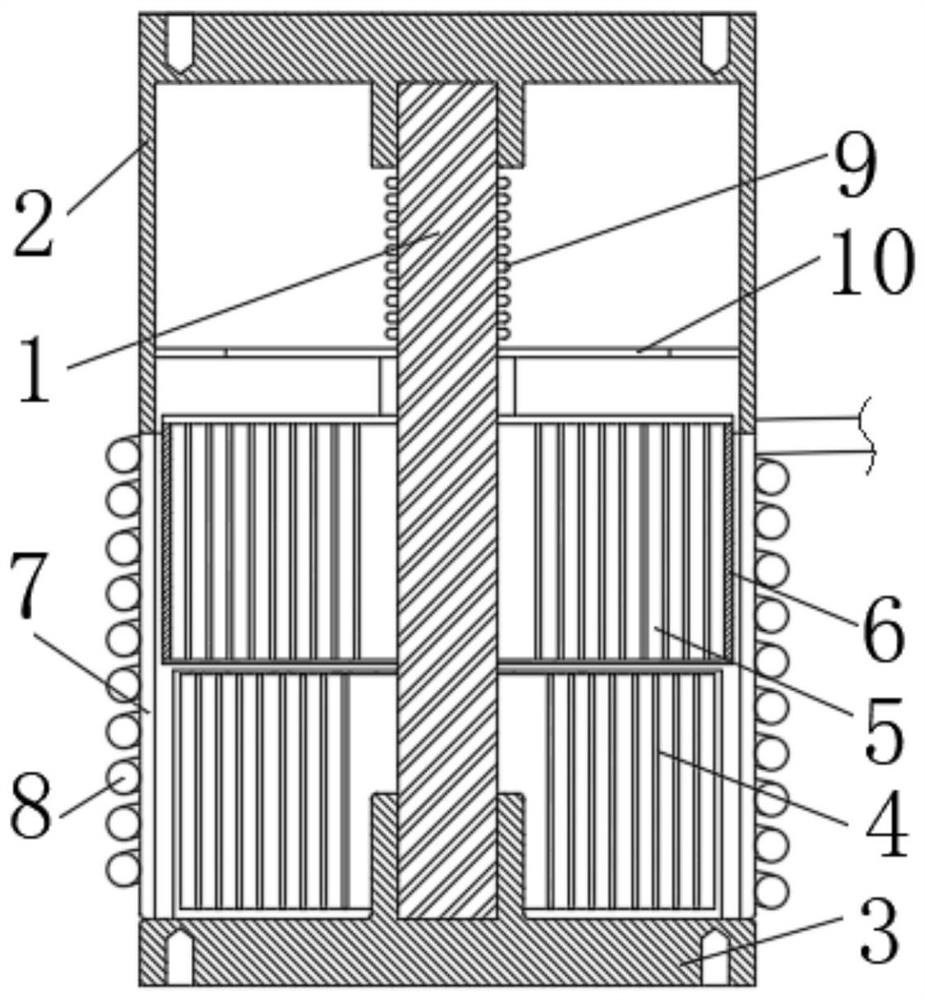

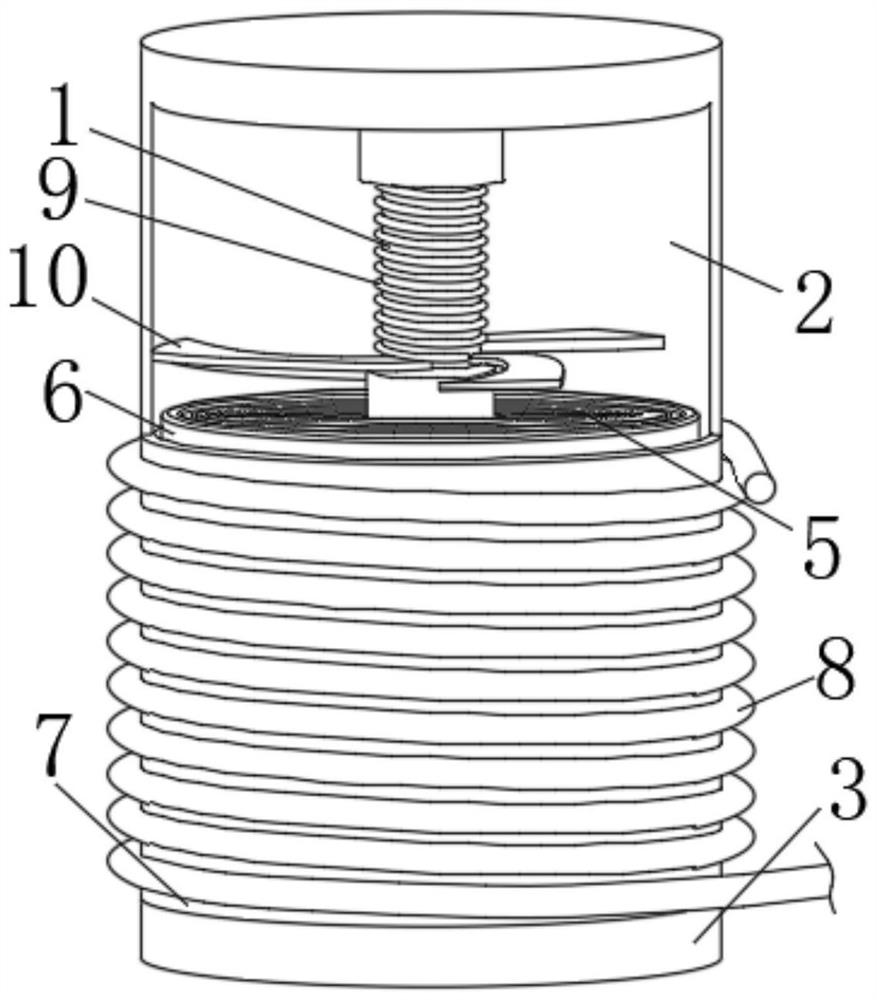

[0038] see Figure 1-Figure 5 , a vacuum capacitor that can change the capacitance, including an insulating rod 1, an upper case 2, a lower case 3, a fixed electrode 4, a movable electrode 5, a magnet 6, an insulating shell 7, a voice coil motor coil 8, a spring 9 and the moving electrode connection piece 10, the top of the insulating rod 1 is connected with the upper case 2, and the bottom of the insulating rod 1 is installed with the lower case 3, and the top of the lower case 3 is connected with the fixed electrode 4, the volume of the vacuum capacitor Smaller, and when adjusting the capacitor capacity, the adjustment speed is fast, the accuracy is high, and the external dimensions of the vacuum capacitor that can change the capacitor capacity are 130mm in length × 73mm in diameter, and the mass m = 1.2 kg;

[0039] The top of the fixed electrode 4 is provided with a movable electrode 5, and the outer wall of the movable electrode 5 is connected with a magnet 6. The direction

Embodiment 2

[0053] In order to compare the parameter difference between this embodiment and the existing vacuum capacitor whose capacitance can be changed, compare the existing capacitor model SCV-205G with the vacuum capacitor whose capacitance can be changed in this embodiment:

[0054] The external dimension of the vacuum capacitor whose capacitor model is SCV-205G is set to be 140 mm in length x 73 mm in diameter, and the weight is W=1.3 kg. The polar height h of the two capacitors is 0-35 mm. Rotate one circle, the moving electrode moves 2.9 mm, 35 mm-500 picofarads, that is, 1 mm-14.3 picofarads, 12 circles-500 picofarads, then 1 circle-41.7 picofarads, that is, rotate one circle, the moving electrode moves 2.9 mm, the capacitance capacity changes by 41.47 picofarads.

[0055] In this embodiment, the external dimensions of the variable vacuum capacitor are 130 mm long x 73 mm in diameter, and the mass m=1.2 kg. When the force generated by the coil 8 of the voice coil motor and the forc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap