Hexagonal flange face extrusion sealing bolt

A technology of extrusion sealing and flange surface, applied in the direction of bolts, screws, nuts, etc., can solve the problems of poor bolt sealing, and achieve the effect of enhancing anti-vibration performance and good vibration-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

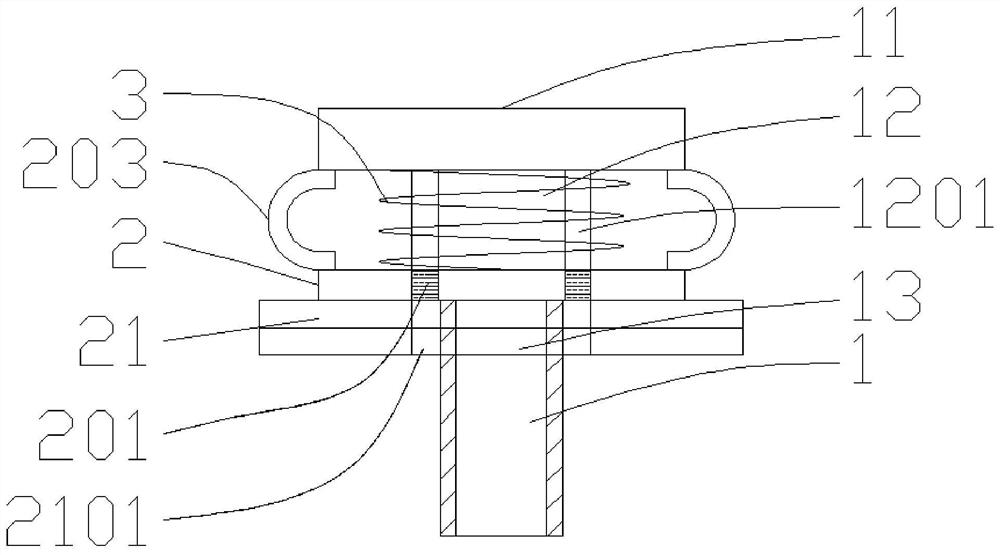

[0013] refer to figure 1 , a hexagonal flange surface extrusion sealing bolt of the present invention, comprising a bolt main body 1, a hexagonal nut 11, a round rod 12, an externally threaded rod 13, a hexagonal round pipe 2, a flange 21, and a spring 3, the bolt main body 1 It consists of a hexagonal nut 11, a round rod 12, and an externally threaded rod 13. The lower end surface of the hexagonal nut 11 is provided with a vertically arranged round rod 12, and the lower end surface of the round rod 12 is provided with a vertically arranged externally threaded rod 13. Hex nut 11, round rod 12, externally threaded rod 13 are coaxial, and the outer diameters of hexagonal nut 11, round rod 12, and externally threaded rod 13 decrease progressively. A spring 3 is connected between the tube 2 and the hexagonal nut 11, the spring 3 is set on the round rod 12, the lower end of the hexagonal tube 2 is provided with a coaxial flange 21, and the inner diameters of the hexagonal tube 2 and t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap