Low-emission backflow combustion chamber adopting circumferential and tangential oil supply mode

A recirculation combustion chamber, low-emission technology, applied in the field of aero-engines, can solve the problems of low pressure loss, large nozzle spacing ratio, difficult low-polluting combustion solutions, etc., to ensure transition state characteristics, small radial size, and low pollution. Potential inhibiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment, technical scheme of the present invention is described further:

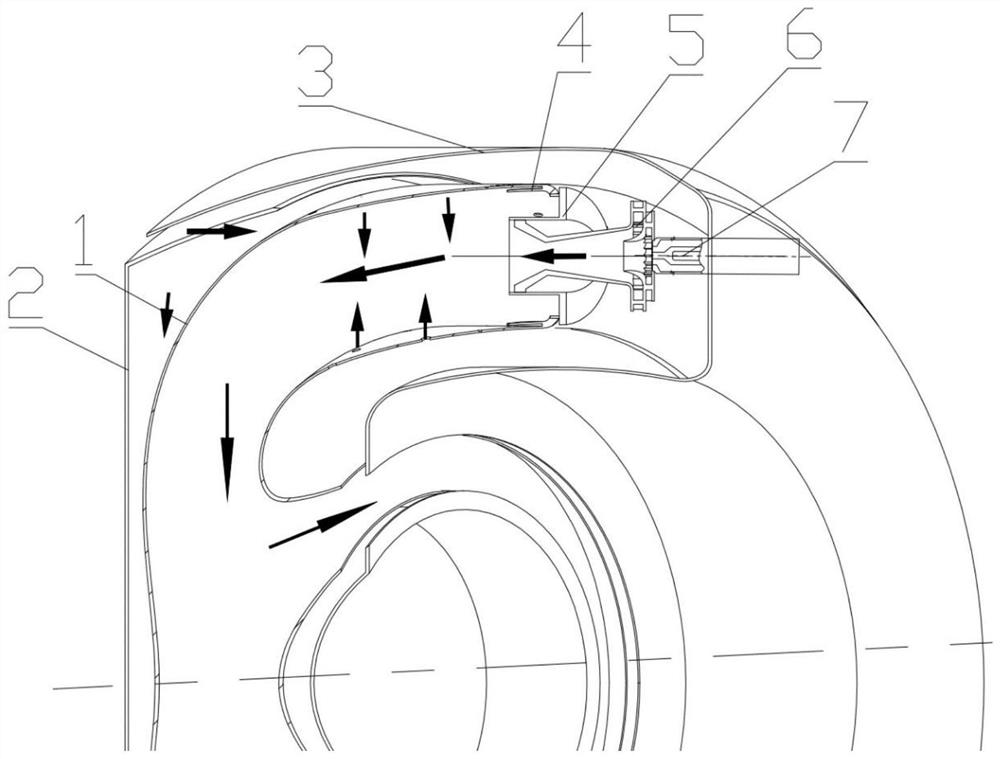

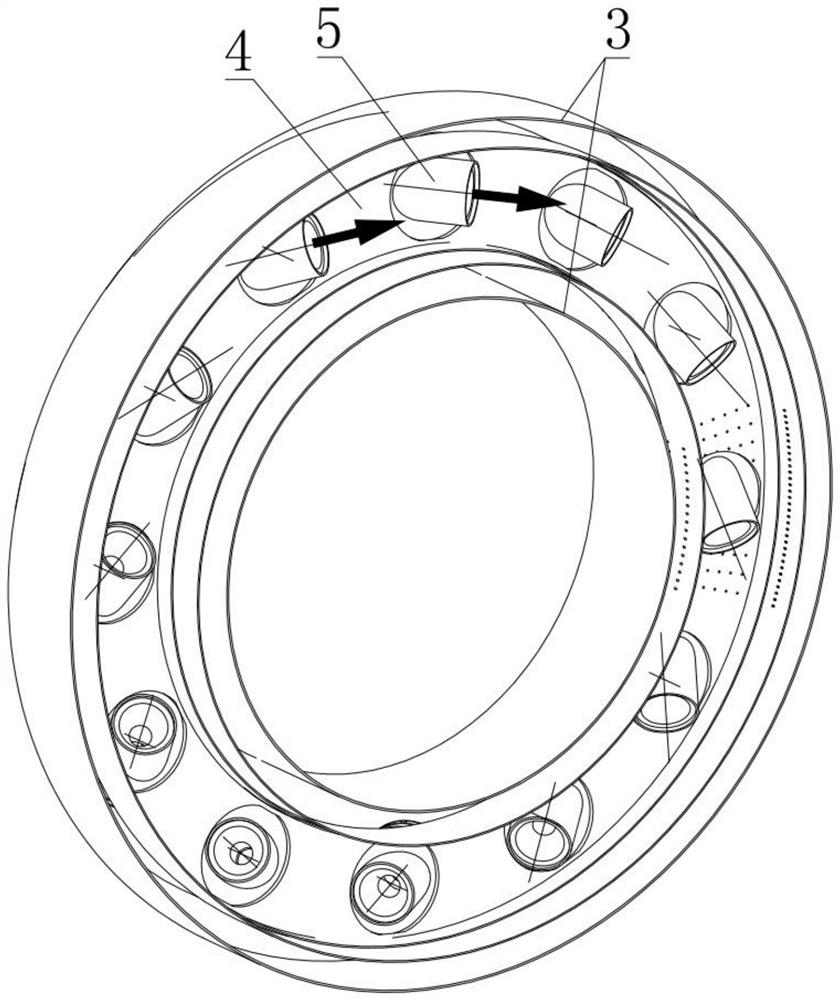

[0024] Such as Figure 1-2 Shown is a low-emission recirculation combustor with circumferential tangential oil supply, including: flame tube elbow 1, radial diffuser 2, combustion chamber casing 3, flame tube head 4, swirl installation Seat 5, oblique premixing vortex 6 and fuel nozzle 7, the radial diffuser 2 is installed inside the combustion chamber casing 3 from the tail end forward, and the flame tube elbow 1 is placed in the Inside the radial diffuser 2, the head end of the flame tube elbow 1 is provided with the flame tube head 4, the flame tube head 4 is provided with the vortexer mounting seat 5, and the chamfered pre-cut The vortex mixer 6 is installed in the vortex mixer mounting seat 5 , and the fuel nozzle 7 communicates with the flame cylinder elbow 1 through the obliquely cut premix vortex 6 .

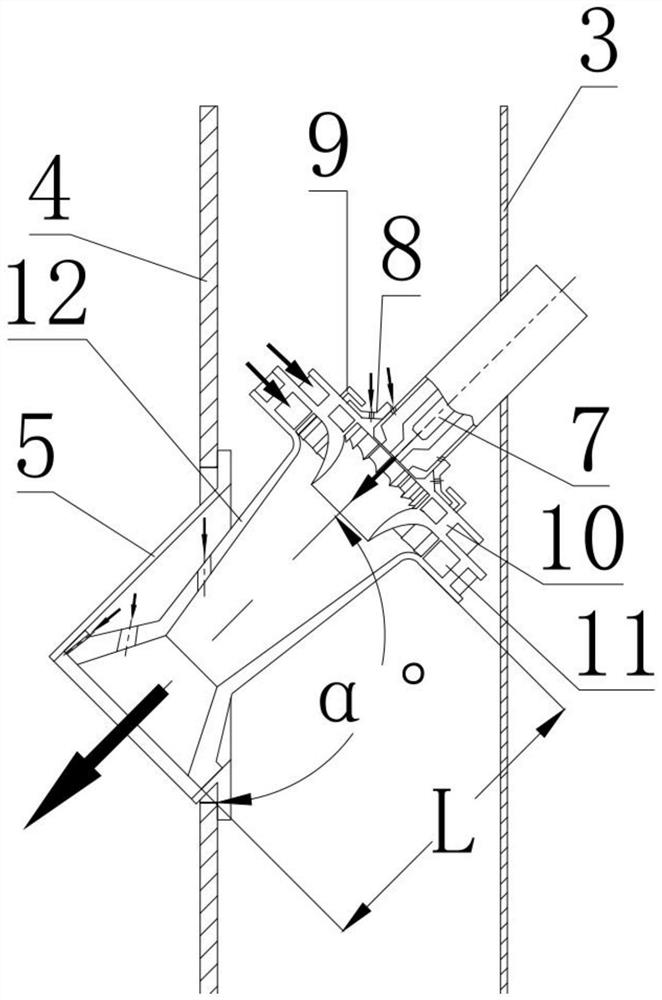

[0025] Such as image 3 As shown,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap