Method for strengthening cold-formed thin-walled steel column based on geopolymer foam concrete

A foamed concrete and geopolymer technology, applied in the directions of columns, piers, pillars, etc., can solve the problems of low bearing capacity, achieve good seismic performance, eliminate empty drum sounds, and have good integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

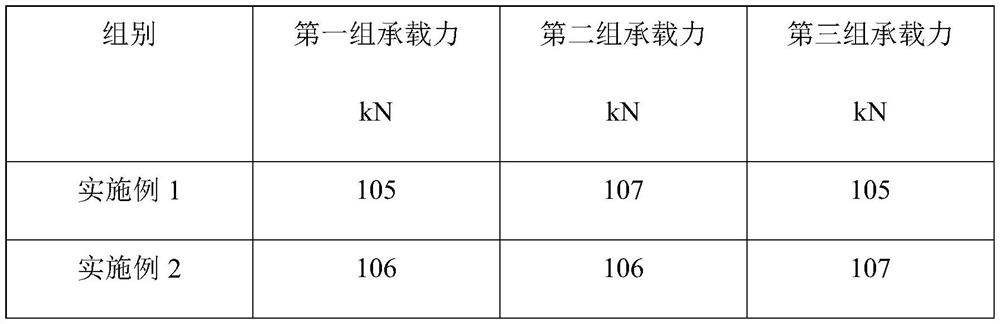

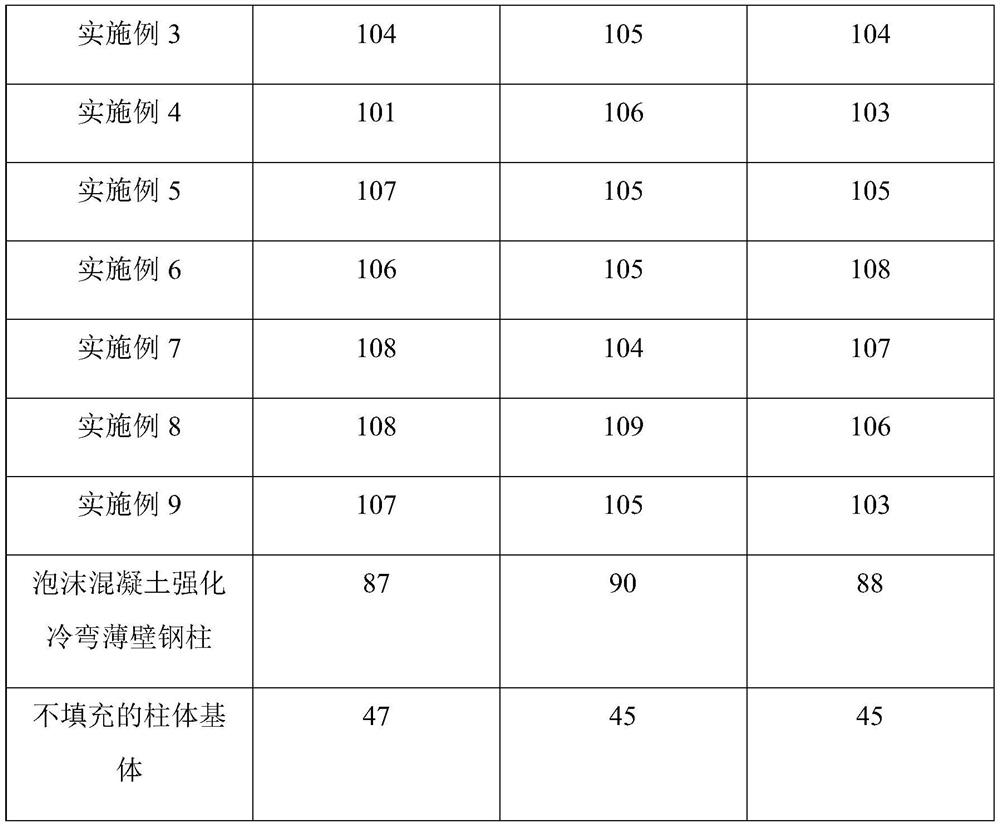

Examples

Embodiment 1

[0033] A method for strengthening cold-formed thin-walled steel columns based on geopolymer foam concrete, including:

[0034] S1: Construct the column matrix

[0035] Use cold-formed thin-walled steel to construct the surrounding column matrix;

[0036] S2: Preparation of geopolymer foam concrete

[0037] S2-1: Ingredients

[0038] According to parts by weight: 190 parts of slag powder, 105 parts of fly ash, 40 parts of construction waste powder, 11 parts of polypropylene short fiber, 64 parts of alkali activator, 5 parts of foaming agent, and 150 parts of water; among them, construction Garbage powder is specifically clay bricks, ceramic fragments, and waste glass mixed in a mass percentage ratio of 3:1:1.7 and crushed into a mixed powder with a fineness of 0.08mm;

[0039] The alkali activator specifically includes 65% water glass and 35% sodium hydroxide; the modulus of water glass is 2.4, and the solid content is 40.2%;

[0040] Foaming agent specifically includes 72% an

Embodiment 2

[0051] A method for strengthening cold-formed thin-walled steel columns based on geopolymer foam concrete, including:

[0052] S1: Construct the column matrix

[0053] Use cold-formed thin-walled steel to construct the surrounding column matrix;

[0054] S2: Preparation of geopolymer foam concrete

[0055] S2-1: Ingredients

[0056] According to parts by weight: 200 parts of slag powder, 120 parts of fly ash, 60 parts of construction waste powder, 13 parts of polypropylene short fiber, 70 parts of alkali activator, 8 parts of foaming agent, and 162 parts of water; among them, construction Garbage powder is specifically clay bricks, ceramic fragments, and waste glass mixed in a mass percentage of 4:1:1.8 and crushed into a mixed powder with a fineness of 0.08mm;

[0057] The alkali activator specifically includes 70% water glass and 230% sodium hydroxide; the modulus of water glass is 2.4, and the solid content is 40.2%;

[0058] Foaming agent specifically includes 75% animal

Embodiment 3

[0069] A method for strengthening cold-formed thin-walled steel columns based on geopolymer foam concrete, including:

[0070] S1: Construct the column matrix

[0071] Use cold-formed thin-walled steel to construct the surrounding column matrix;

[0072] S2: Preparation of geopolymer foam concrete

[0073] S2-1: Ingredients

[0074] According to parts by weight: 215 parts of slag powder, 135 parts of fly ash, 73 parts of construction waste powder, 15 parts of polypropylene short fiber, 88 parts of alkali activator, 11 parts of foaming agent, and 182 parts of water; among them, construction Garbage powder is specifically clay bricks, ceramic fragments, and waste glass mixed in a mass percentage of 5:1:2 and crushed into a mixed powder with a fineness of 0.08mm;

[0075] The alkali activator specifically includes 73% water glass and 27% sodium hydroxide; the modulus of water glass is 2.4, and the solid content is 40.2%;

[0076] Foaming agent specifically includes 80% animal pr

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap