Injection device, die casting machine and die casting method

A material end and material technology, applied in the injection device and its die-casting machine and its die-casting field, can solve the problems of oxidation and affecting the quality of finished products, and achieve the effects of small temperature difference, good quality of finished products, and less heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

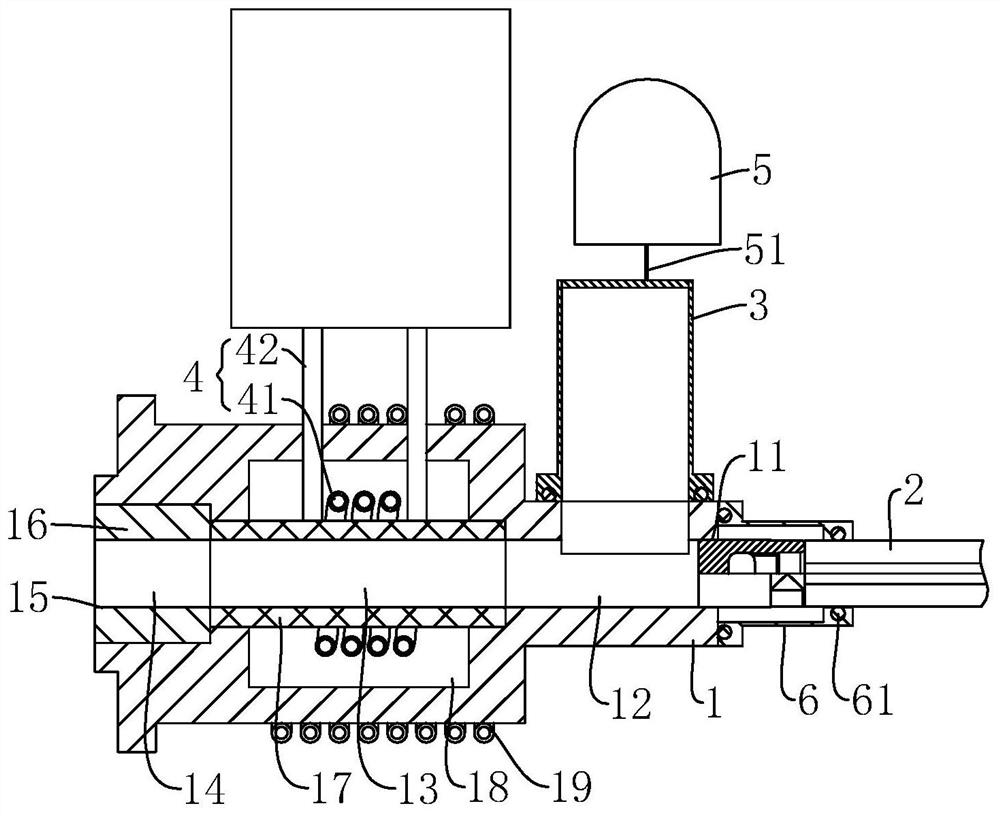

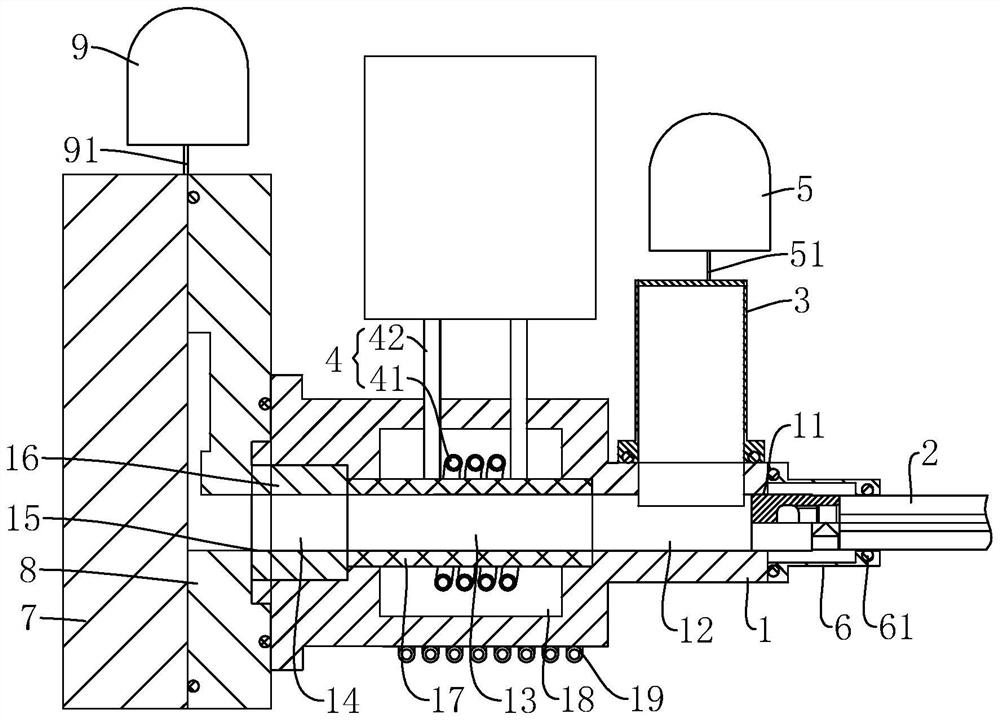

[0033] A material injection device, comprising a injection cylinder 1, a material pushing hammer 2, a feeding bin 3 and a heating mechanism 4. The injection cylinder 1 is provided with an inlet 11, a blanking chamber 12, a heating cavity 13, injection cavity 14 and outlet 15, specifically, injection cylinder 1 is arranged horizontally, inlet 11 and outlet 15 are respectively located at both ends of injection cylinder 1; pusher hammer 2 is slidably connected to inlet 11, pusher hammer 2 has a pushing end, which moves along the axial direction of the injection cylinder 1, and the pushing end can push the material to move from the blanking chamber 12 to the heating chamber 13, the injection chamber 14 and the outlet 15, and then to the blanking chamber 12, specifically, the end of the pusher hammer 2 away from the pusher end can be connected to a power source, and the power source pushes the pusher hammer 2 to move along the axis of the injection cylinder 1; the feed bin 3 is connect

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap