Automatic cattail harvesting, cutting and sorting device

A technology for sorting devices and driving devices, which is applied in the direction of cutters, harvesters, agricultural machinery and implements, etc., which can solve problems such as potential safety hazards, energy consumption of laborers, and impact on physical health, so as to improve work efficiency and ensure physical health Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

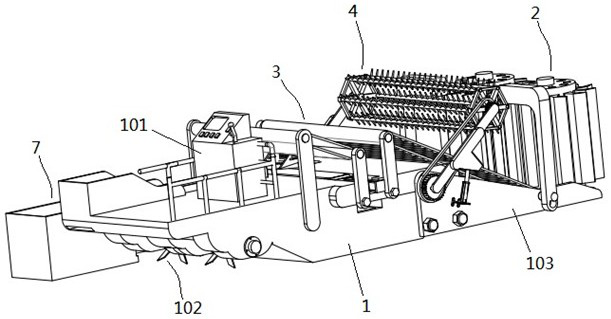

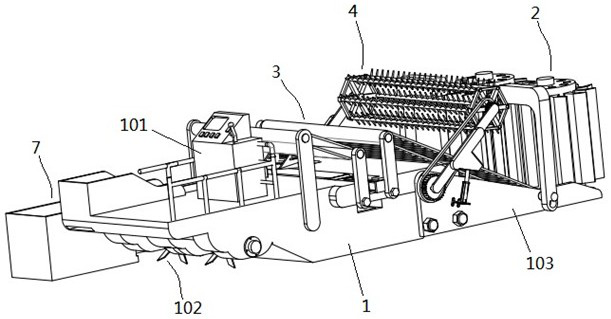

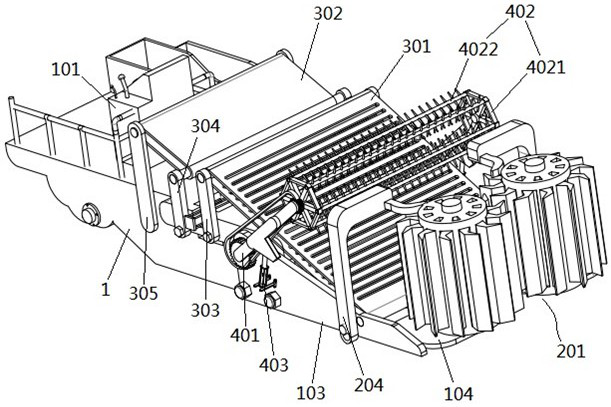

[0034] Embodiment 1: as Figure 1-9As shown, a kind of automated cattail pickling cutting and sorting device includes a hull 1, a harvesting mechanism 2, a packing mechanism 3, a carding mechanism 4, a first cutting and pushing mechanism 5, a second cutting and pushing mechanism 6 and a sorting mechanism. The collection mechanism 7; the hull 1 is provided with an electric control device 101 and a driving mechanism 102, and front guard plates 103 are provided on both sides of the front end of the hull 1, and shovel plates 104 are connected between the front guard plates 103; the harvesting mechanism 2 is connected to the shovel plate 104; one end of the shoveling mechanism 3 is located above the shovel plate 104, and the other end is connected to the hull 1; the carding mechanism 4 is connected to the front guard plate 103, and the carding mechanism 4 is located Above the front end of the mechanism 3; the first cutting and pushing mechanism 5 and the second cutting and pushing mec

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap