IGBT packaging pneumatic pressing riveting device

A pneumatic, riveting ring technology, applied in electrical components, metal processing equipment, metal processing and other directions, can solve the problems of riveting ring not in place, riveting ring pressing in place, etc., to liberate labor, improve riveting efficiency, and ensure safe operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

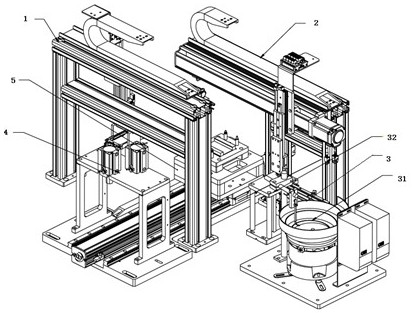

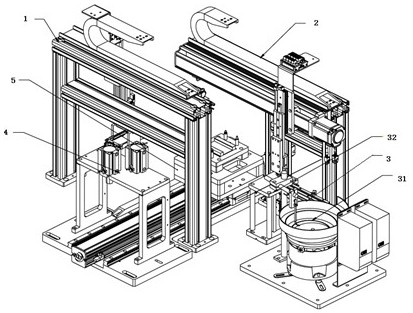

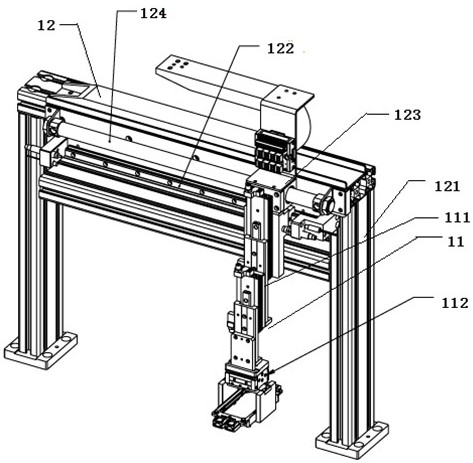

[0053] As an embodiment of the present invention, please refer to figure 1 A pneumatic riveting device for IGBT packaging, including a product loading and unloading mechanism 1 and a riveting ring loading and unloading mechanism 2, the product loading and unloading mechanism 1 and the riveting ring loading and unloading mechanism 2 are arranged relatively parallel, and also includes:

[0054] The riveting ring vibrating plate distributing mechanism 3, the riveting ring vibrating disc distributing mechanism 3 is set on the side of the riveting ring loading and unloading and conveying mechanism 2, and is used to make the riveting rings be arranged and discharged in an orderly manner and individually distributed, It is convenient for the riveting ring loading and unloading and conveying mechanism 2 to grab the riveting ring;

[0055] Pneumatic riveting mechanism 4, the pneumatic riveting mechanism 4 is located in the middle between the product loading and unloading and conveying mec

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap