Material shaking device for fermentation tank

The technology of fermentation tank and feed tank is applied in the field of material shaking device for fermentation tank, which can solve the problems of low efficiency and high labor cost of organic fertilizer, and achieve the effects of reducing re-transfer, uniform organic fertilizer and reducing labor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

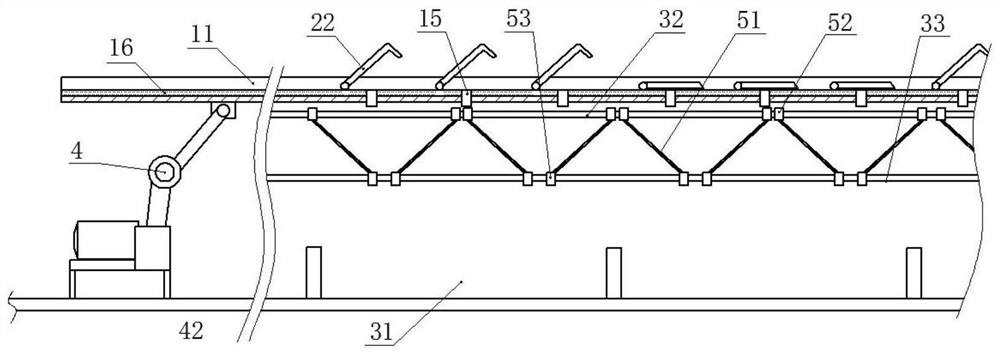

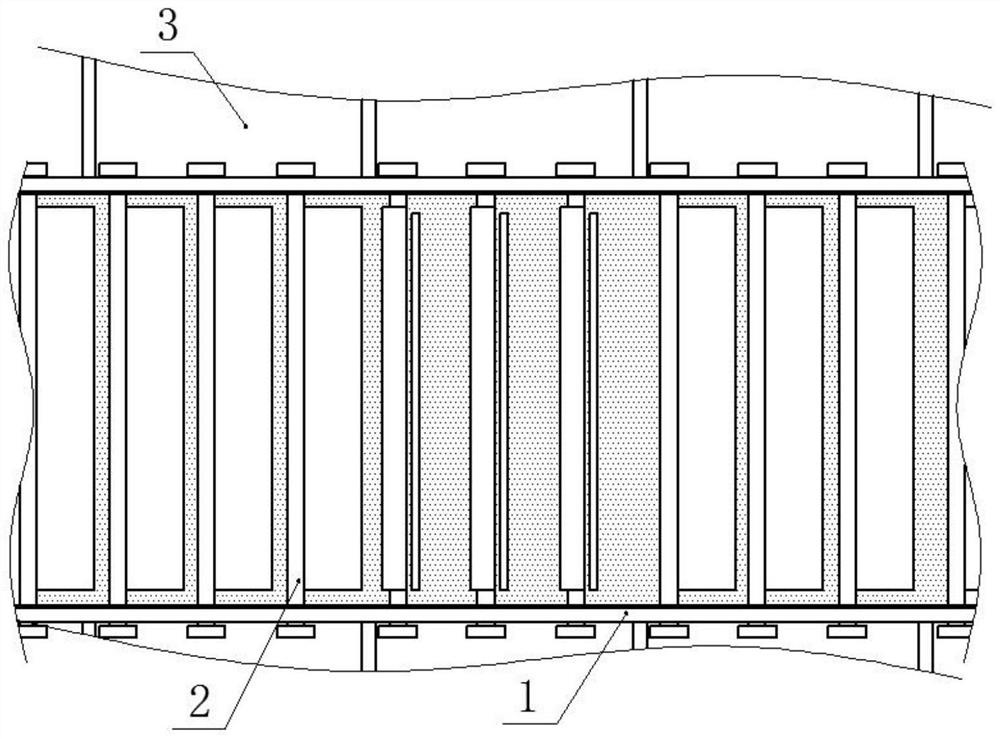

[0029] Such as Figure 1 to Figure 5 As shown, a shaking device for a fermentation tank includes a shaking tank assembly 1, a shaking baffle assembly 2, a shaking tank frame assembly 3 and a power assembly 4, and the shaking tank assembly 1 includes a feeding tank 11 , the groove bottom of feeding chute 11 is fixedly bonded with non-slip conveyor belt 16, and the groove bottom of feeding chute 11 is provided with a plurality of discharge holes 15, and feeding chute 11 is provided with external thread body 12, and external thread body 12 is provided with through hole 13 and limiting holes 14, there are multiple limiting holes 14, and the plurality of limiting holes 14 are evenly distributed around the external threaded body 12, the shaker baffle assembly 2 includes a baffle rotating shaft 21, and the baffle rotating shaft 21 is fixedly connected with a shiel

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap