Windlass with multi-angle flexible rotating cutter bar mechanism

A technology of rotating knife and rod mechanism, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of uneven ceramic surface, different thickness of soil embryo, complicated operation, etc., achieve uniform thickness, convenient reuse, improve The effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

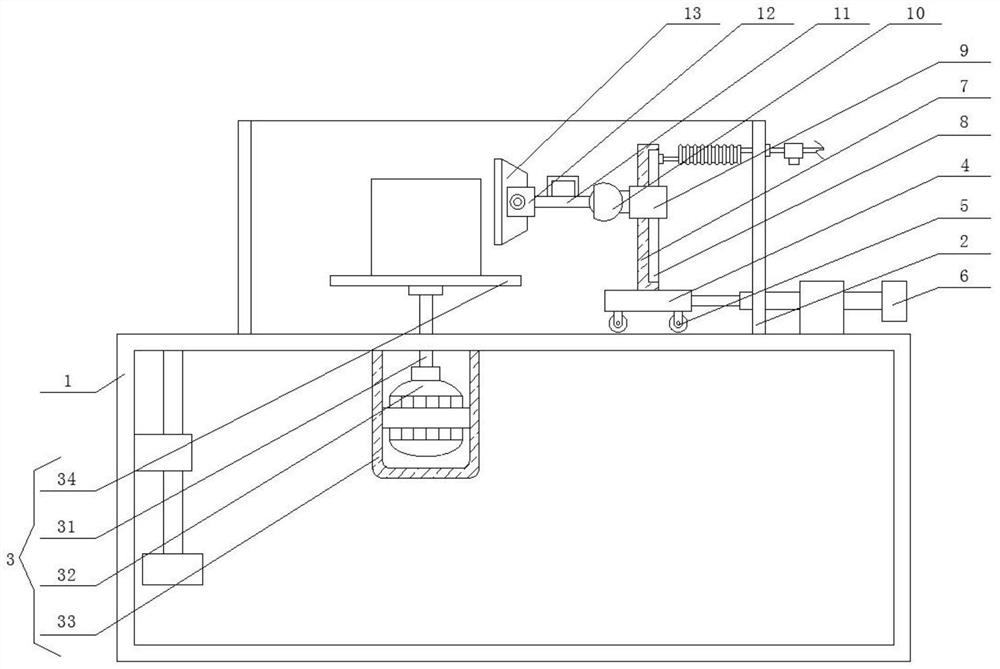

[0032] Example one

[0033] See figure 1 The present invention provides a flexible multi-angle includes rotating the arbor windlass mechanism car, car hauler 1 comprises a support frame, the turret mechanism 3 and the movable block 4.

[0034] The top of the support frame 1 is fixedly connected to the protective plate 2, the protective plate 2 consists of three rectangular plates; may be produced during the molding of the ceramic clay in the embryo, facilitate soil be blocked by shielding plate 2 is provided, to avoid splashing mud body of staff, so as to bring convenience for ceramic soil embryo production.

[0035] 3 turret mechanism 31 includes a rotating shaft, the rotating shaft 31 at the top of the bracket activities sleeved frame 1, and the bottom end of the rotary shaft 31 is fixedly connected to the rotary electric machine 32, by machining the outer rotating electrical machine 33 with the cartridge lumen 132 of the stent frame fixedly connected to the top, the top of the rot

Example Embodiment

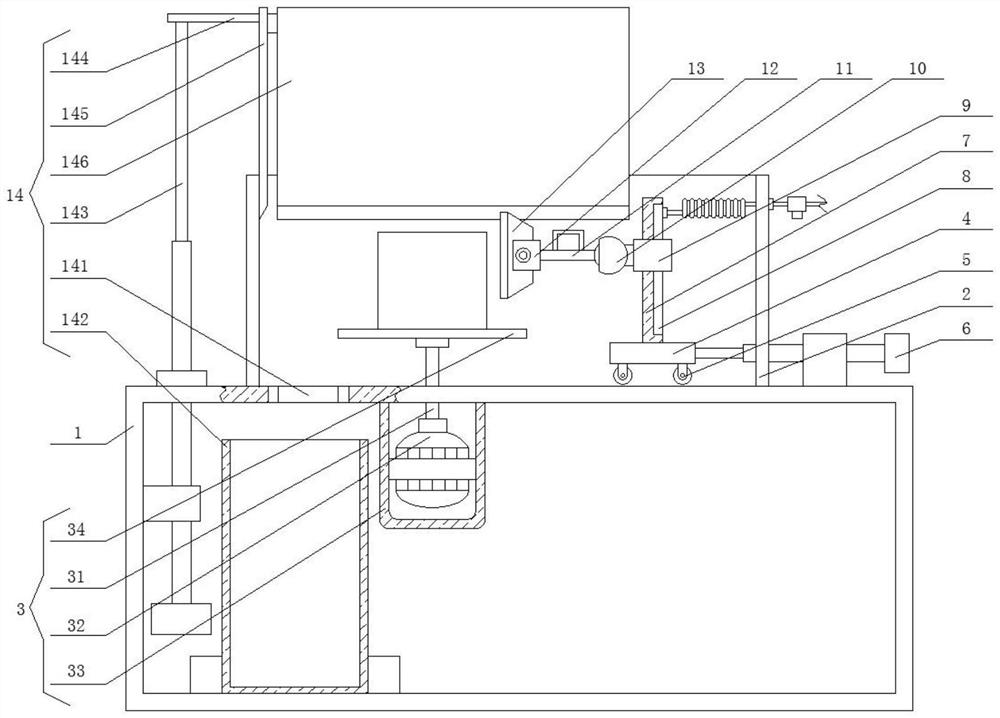

[0040] Example 2

[0041] See figure 2 Includes multi-angle flexible rotary knife bar mechanism windlass vehicle of the present embodiment increases the cleaning means 14 based on Embodiment 1, the cleaning means 14 comprises a feed port 141, collection tank 142 and the lift ram 143, doghouse 141 opened at the top of the support frame 1, at the bottom of the collection tank 142 disposed lumen stent frame 1, the push rod 143 fixed to the lift at the top of the sleeved stent frame 1, the lifting pusher tip 143 is fixedly connected with a fixing plate 144, fixed plate 144 are fixedly connected to one side of the blade 145 One, One side of the blade 145 is fixedly connected with the blade II 146, collection tank 142 is located below the feed port 141, and both sides of the bottom collection tank 142 with a rubber block rubber block is fixedly mounted between the bottom of the support frame 1 lumen, II One blade 145 and the blade 146 is fixedly connected by a connecting block, and II One

Example Embodiment

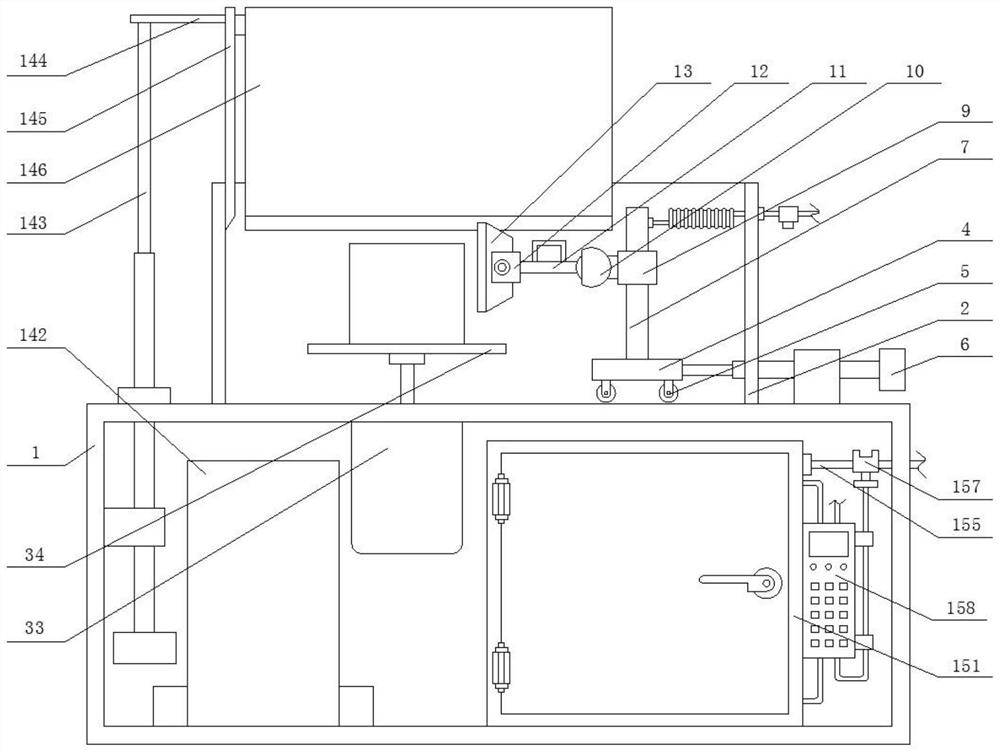

[0043] Example three

[0044] See Figure 3-6 , The present embodiment includes a multi-angle rotation of the arbor can be flexibly embodiment windlass mechanism on the basis of the vehicle according to the second embodiment increases the storage means 15, storage means 15 includes a storage tank 151, storage tank 151 is fixed to the inside is connected to network 152 is placed, and the bottom of the storage tank 151 is fixedly connected with the lumen of the heating plate 153, plate 153 is fixed inside the heating resistance wire is attached, is fixed to the inside of the storage tank 151 is mounted temperature and humidity sensing probe 154, and the top of the storage tank 151 is fixedly connected to the lumen bottom feed pipe 155, the air supply pipe 155 is fixedly mounted nozzle 156, the nozzle 156 is located inside the storage tank 151, the head 156 and the number is five, five nozzles 156 equally spaced at the bottom of feed pipe 155, and for outer tube 155 is fixedly attached t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap