Underwater anti-rotation empennage and direct-reading CTD with same

An anti-rotation, direct-reading technology, used in underwater ships, underwater operation equipment, transportation and packaging, etc., can solve problems such as affecting the normal operation of oceanographic surveys, high performance requirements for electric swivels, time-consuming and labor-intensive, etc. The effect of underwater rotation, ensuring work ability and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

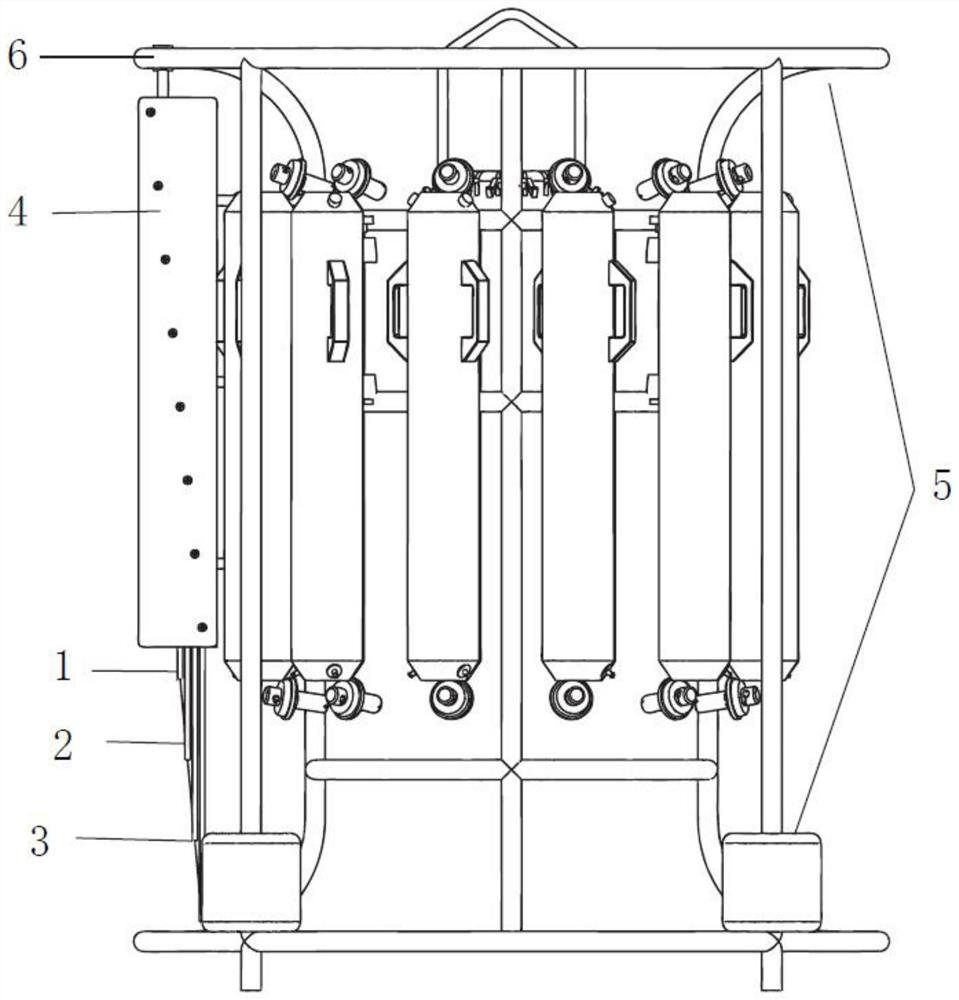

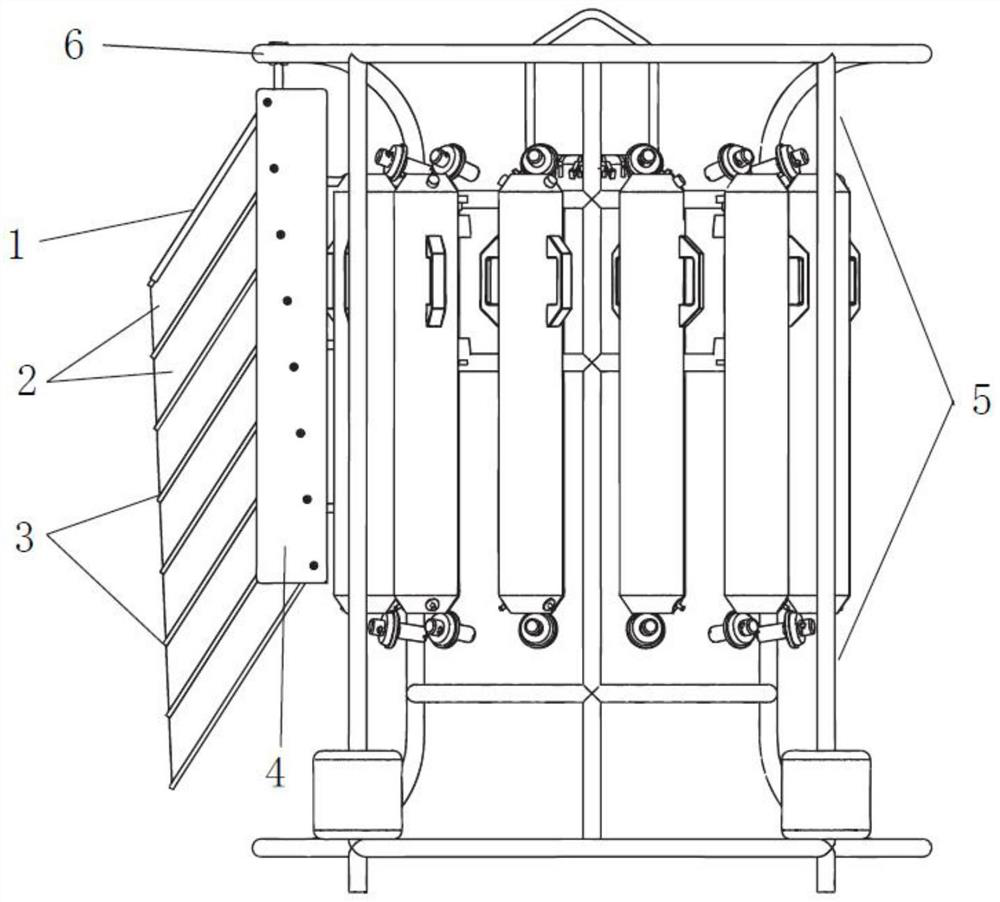

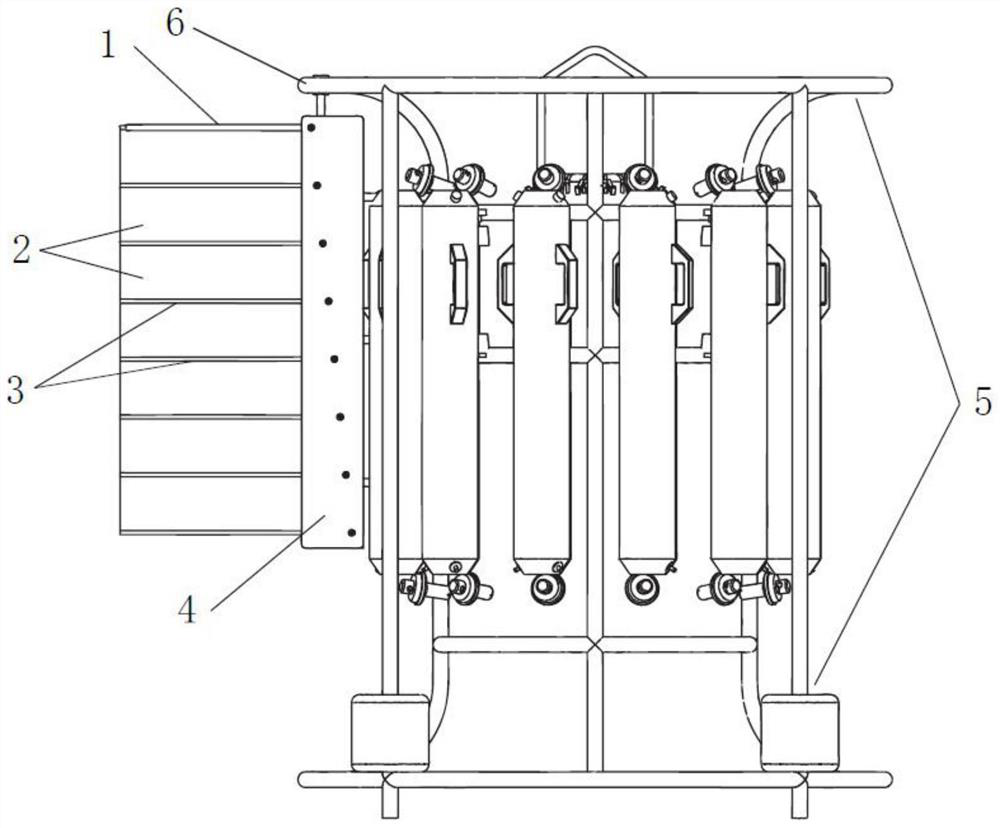

[0025] An underwater anti-rotation tail, comprising an anti-rotation piece that prevents a direct-reading CTD from rotating underwater in a circumferential direction, and the anti-rotation piece is connected to the water collection frame 6 of the direct-reading CTD. Preferably, the anti-rotation member includes a supporting frame and a high-strength waterproof cloth 2, and the high-strength waterproof cloth 2 is arranged on the supporting frame. Preferably, the support frame is fixedly connected to the water collection frame 6 .

[0026] In the prior art, the direct-reading CTD device is usually a cylindrical symmetrical structure. In this embodiment, an empennage is arranged on one side of the direct-reading CTD device so that the direct-reading CTD device becomes an asymmetric structure. Under the premise of making the direct-reading CTD equipment stable in one direction underwater, it effectively prevents the underwater rotation of the equipment without adding additional other

Embodiment 2

[0029] The difference from Embodiment 1 is that the underwater anti-rotation fin provided by this embodiment can be stored. Specifically, the support frame includes a pressure-resistant buoyancy rod 1 and a stainless steel frame 3 , and the pressure-resistant buoyancy rod 1 is arranged on the upper part of the stainless steel frame 3 . Preferably, it also includes a storage bracket 4 for storing the high-strength waterproof cloth 2, the storage bracket 4 is fixedly connected to the water collection frame 6, and the pressure-resistant buoyancy rod 1 and the stainless steel skeleton 3 are respectively rotatably connected to the storage bracket 4 . Preferably, the pressure-resistant buoyancy rod 1 is made of glass microspheres. Preferably, the storage bracket 4 is U-shaped. Preferably, the storage bracket 4 is made of stainless steel.

[0030] In this embodiment, when the direct-reading CTD device is on the deck, the anti-rotation part will be in a drooping state due to gravity,

Embodiment 3

[0033] A direct-reading CTD has the underwater anti-rotation tail as described in Embodiment 1 or Embodiment 2.

[0034] The direct-reading CTD provided by this embodiment effectively avoids the phenomenon of steel cable knotting, and also avoids the hidden dangers of breaking the steel cable at the knot and causing equipment loss due to the swaying and pitching of the ship under high sea conditions , reducing unnecessary losses and ensuring the working capacity of high sea conditions.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap