Luminescent compound, luminescent layer material, organic electroluminescent device, and electronic device

A technology of light-emitting compounds and atoms, which is applied in the fields of light-emitting layer materials, light-emitting compounds, organic electroluminescent devices and electronic equipment, can solve the problems of not being able to meet the requirements of high color purity in the display field, loss of energy, wide spectrum, etc., to achieve Meet the photoelectric performance requirements, suppress exciton quenching, and avoid stacking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

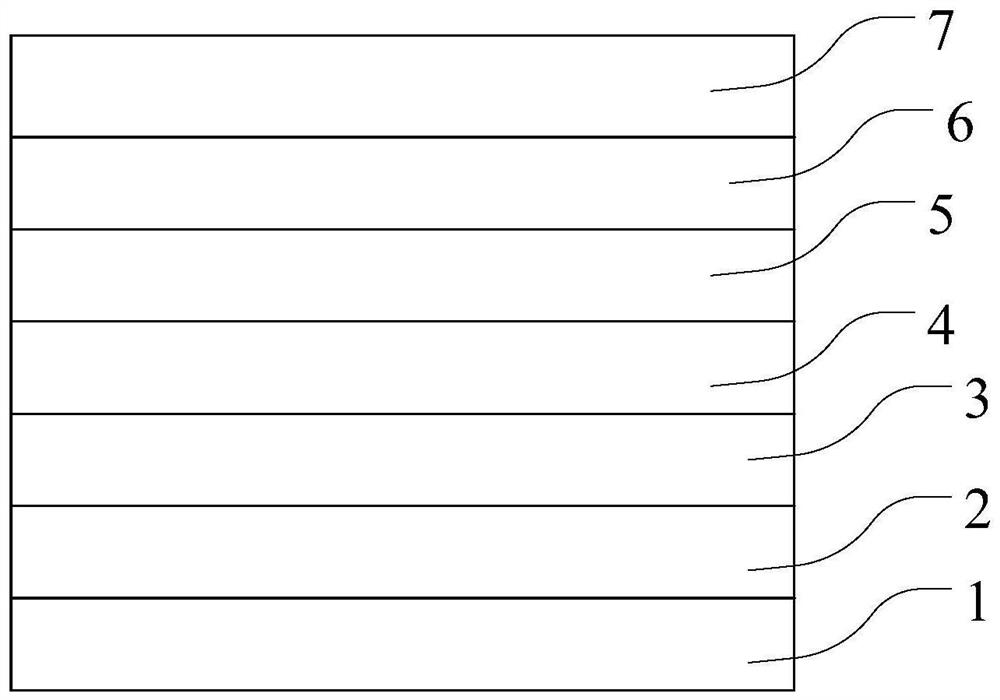

Image

Examples

preparation example Construction

[0043] Provide the preparation method of above-mentioned (1-1) of the present invention below:

[0044]

[0045] Some specific structural formulas of structural formula (1-1) of the present invention are given below, and the compound shown in structural formula (1-1) is selected from any one of structural formula (1-1-1)~(1-1-24) :

[0046]

[0047]

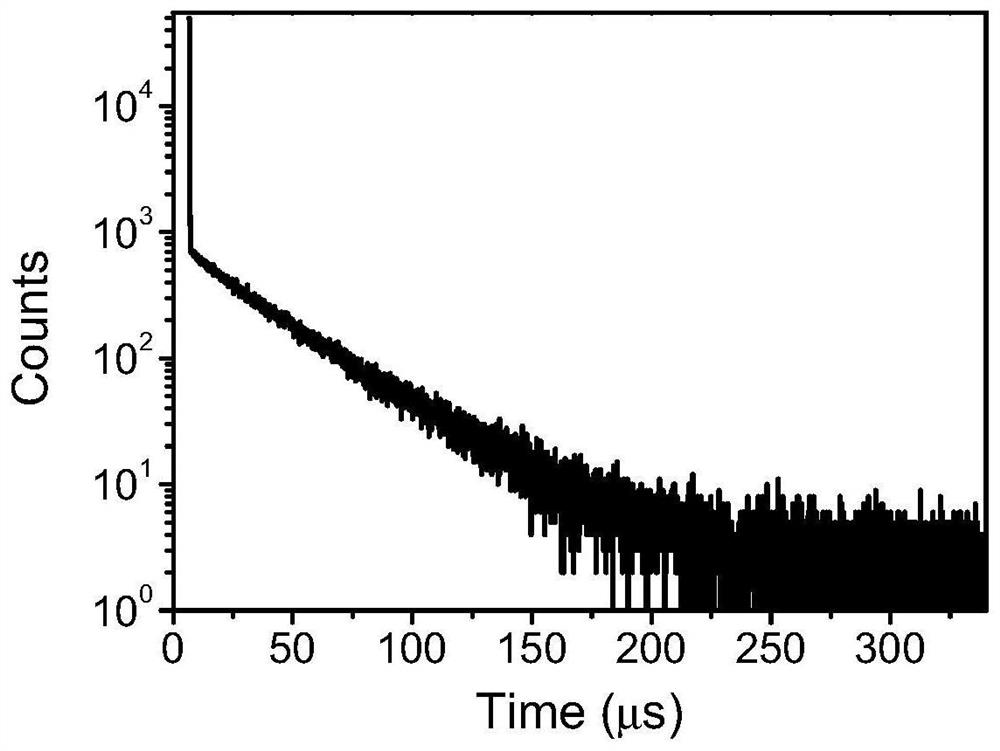

[0048] The use of at least one of the above-mentioned light-emitting compounds is beneficial to the improvement of the fluorescence quantum yield and the reduction of the intensity of the vibration spectrum in the emission spectrum, so that the broadening of the emission spectrum of the compound is reduced, and it is easy to prepare an effective compound with high efficiency and narrow emission spectrum characteristics. Electromechanical Luminescent Devices.

[0049] The compound shown in the structural formula (1-1) that has ring a and ring b can be synthesized by various routes in principle, and wherein preferred synthet

Embodiment 1

[0083] Preparation of Example 1 Luminescent Compound (1-1-1)

[0084]

[0085] Under a nitrogen atmosphere, [1,1'-binaphthyl]-2,2'-diamine (2.7g, 9.5mmol, 1eq), iodobenzene (4.2g, 20.9mmol, 2.2eq), tris(diethylene Benzylacetone) dipalladium (173mg, 0.19mmol, 0.02eq), 1,1'-bis(diphenylphosphino)ferrocene (107mg, 0.19mmol, 0.02eq) and sodium tert-butoxide (2.6g, 28.4 mmol, 3eq) was dispersed in 20mL toluene. React at 120°C for 12 hours. After the reaction, the solvent was spin-dried, and the crude product was further purified by column chromatography using petroleum ether:dichloromethane (90:10). The intermediate product P-1 was obtained in a yield of 3.5 g (yield 85%).

[0086] Under nitrogen atmosphere, intermediate P-1 (3.1g, 7.1mmol, 1eq), sodium hydride (NaH) (0.33g, 14.1mmol, 2eq) and p-cyanotetrafluorobenzene (0.7g, 3.5mmol, 0.5 eq) Disperse in 20 mL of N,N'-dimethylformamide (DMF) and react at room temperature for 8 hours. After the reaction was completed, a large a

Embodiment 2

[0088] Preparation of Example 2 Luminescent Compound (1-1-3)

[0089]

[0090] Under a nitrogen atmosphere, 5-bromo-1,3-difluoro-2-iodobenzene (20.0 g, 62.7 mmol, 1 eq), 4-tert-butylphenol (28.2 g, 188.1 mmol, 3 eq) and sodium hydride ( NaH) (4.5 g, 188.1 mmol, 3 eq) was dispersed in 80 mL of N,N'-dimethylformamide (DMF). The product was stirred at room temperature for 12 hours. After cooling to room temperature, the reactant was poured into ice water, and the precipitate was filtered and washed with water. The crude product was extracted with dichloromethane and water, the organic layer was collected, dried over anhydrous magnesium sulfate, and the solvent was spin-dried, and the crude product was further purified by column chromatography using petroleum ether:dichloromethane (90:10). Intermediate P-3 was obtained with a yield of 29.0 g (yield 80%).

[0091] Under a nitrogen atmosphere, the intermediate P-3 (20.0g, 34.5mmol, 1eq) was dispersed in 150mL of anhydrous m-xylen

PUM

| Property | Measurement | Unit |

|---|---|---|

| Half width | aaaaa | aaaaa |

| Maximum current efficiency | aaaaa | aaaaa |

| Maximum power efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap