Silicon carbide diode detection equipment for function test

A technology of silicon carbide diodes and testing equipment, which is applied in the direction of sorting, etc., can solve the problems of inconvenient insertion and detection, pin bending, etc., and achieve the effect of convenient feeding process, convenient limit, and improved pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

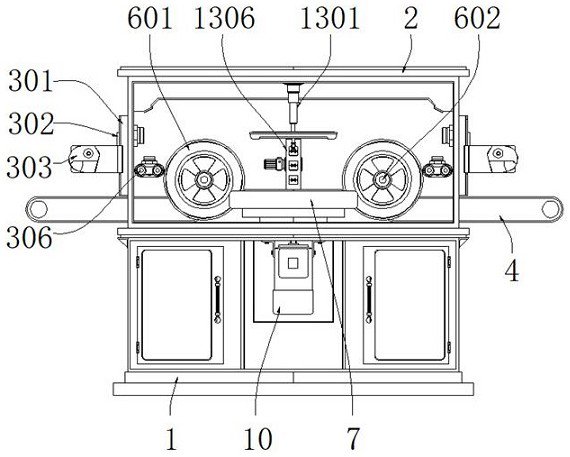

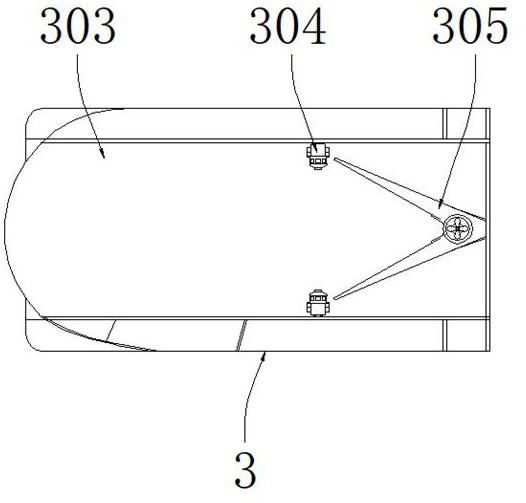

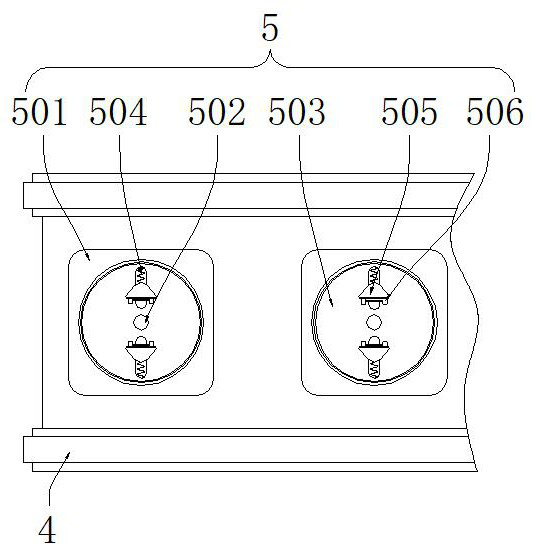

[0031] see Figure 1-8 , the present invention provides a technical solution: a silicon carbide diode detection device for functional testing, including a base 1 and a stable frame 7, a frame 2 is installed on the outside of the top of the base 1, and auxiliary components 3 are connected to both sides of the frame 2, the base 1 Conveyor belts 4 are installed on both sides, and the surface of the conveyor belt 4 is equipped with a limit assembly 5, the inside of the conveyor belt 4 is provided with a feeding assembly 6, and the auxiliary assembly 3 includes slide rails 301, pneumatic sliders 302, auxiliary frames 303, infrared Distance sensor 304, pneumatic scissors 305 and binocular detection camera 306, and slide rail 301 is equipped with pneumatic slider 302, the other end of pneumatic slider 302 is connected with auxiliary frame 303, and auxiliary frame 303 is internally connected with infrared distance sensor 304, Pneumatic scissors 305 are installed on the right side inside

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap