Aluminum veneer curtain wall mounting structure

A technology for installing structures and aluminum veneers, which is applied to walls, building components, building structures, etc., can solve problems such as costing more manpower and time, inconvenient installation of aluminum veneers, time-consuming and labor-intensive work, etc., to reduce manpower and improve Stability, the effect of enhancing waterproof sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

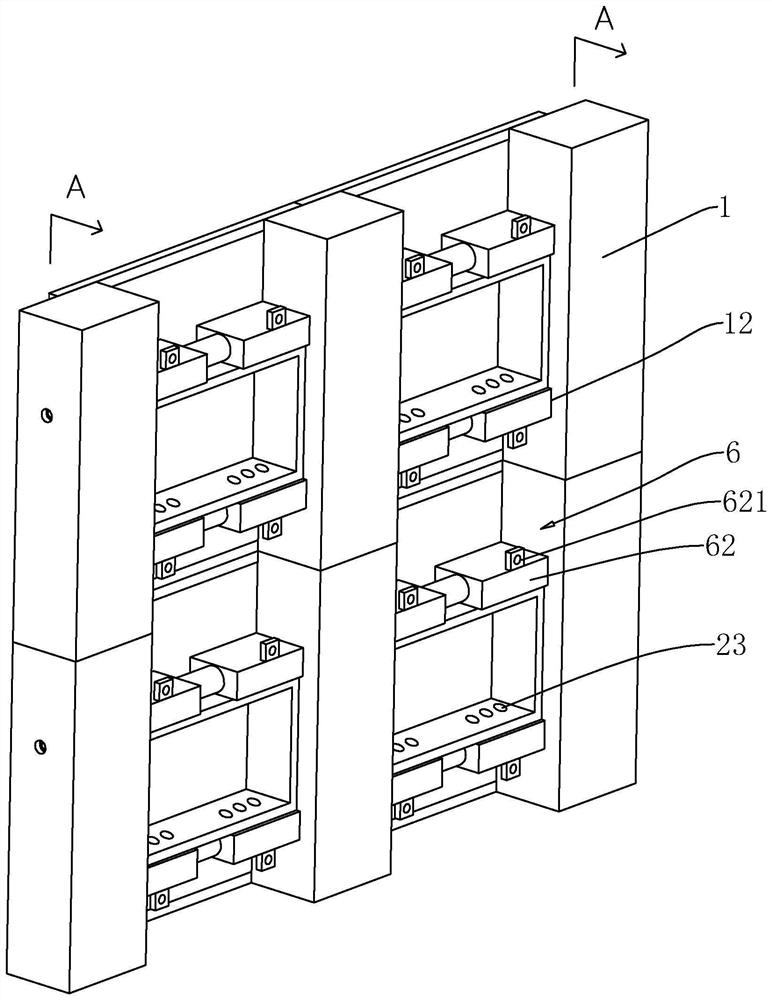

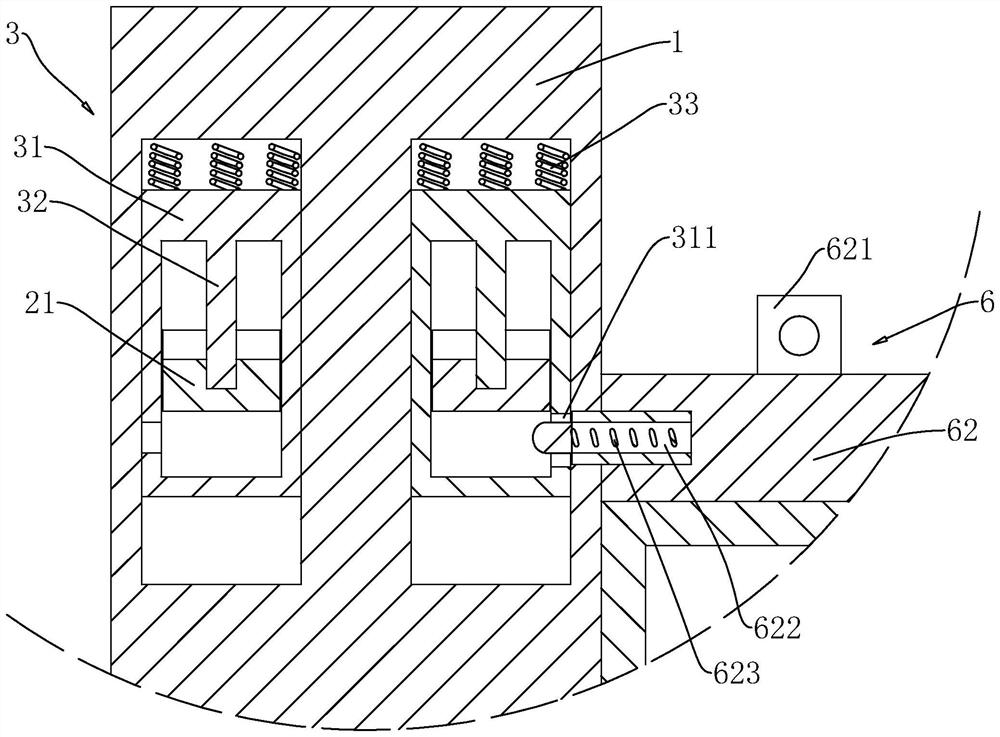

[0032] The following is attached Figure 1-7 The application is described in further detail.

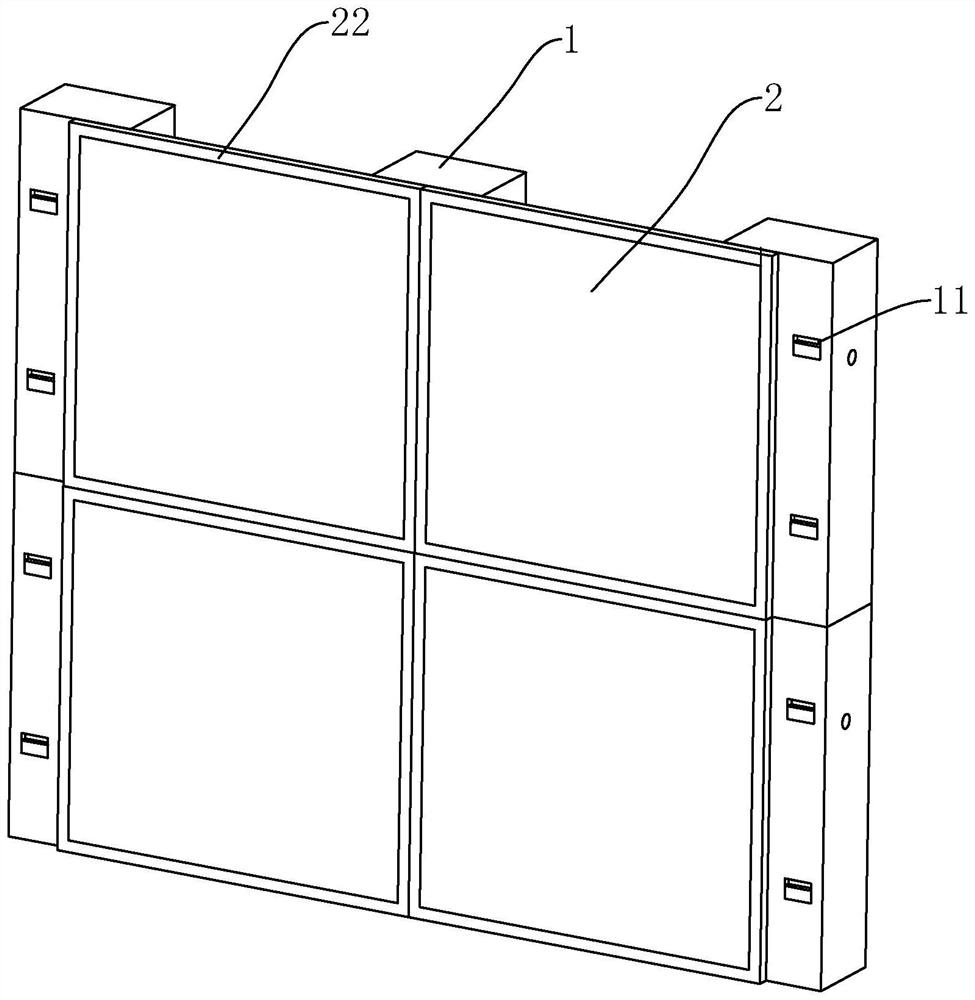

[0033] The embodiment of the present application discloses an aluminum veneer curtain wall installation structure. refer to figure 1 , figure 2The aluminum veneer curtain wall installation structure includes multiple sets of joists 1 for fixed installation on the exterior wall of a building, and panels 2 for installation on the surface of the joists 1 . When the keel 1 is installed on the outer wall of the building, the keel 1 is placed vertically, and the adjacent keel 1 is ensured to be evenly spaced and fixed sequentially along the horizontal direction. Each keel 1 is provided with multiple sets of installation grooves 11 with openings facing the plate body 2 . In this embodiment, four sets of installation grooves 11 are used for illustration. Four sets of mounting grooves 11 are arranged at regular intervals in sequence along the length direction of the keel 1 , and the numb...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap