Unmanned aerial vehicle with spiral feeding and sowing mechanism and use method thereof

A technology of screw feeding and seeding mechanism, which is applied to the direction of sowing seeders, seeder parts, rotorcraft, etc., can solve the problems of inconvenient transportation, large size, and easy collapse of the seeder, and achieve convenient transportation and portability, good use effect, and small size small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

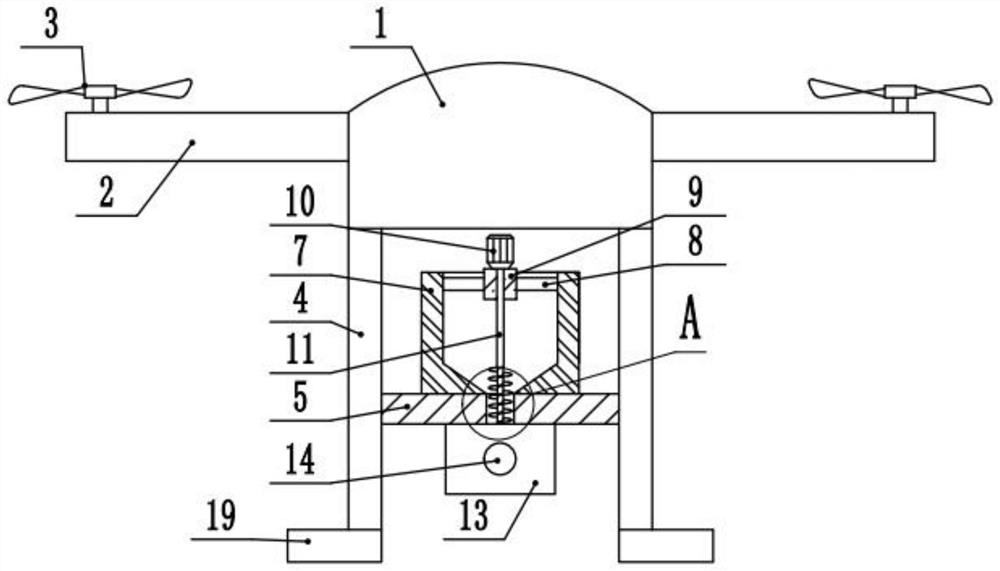

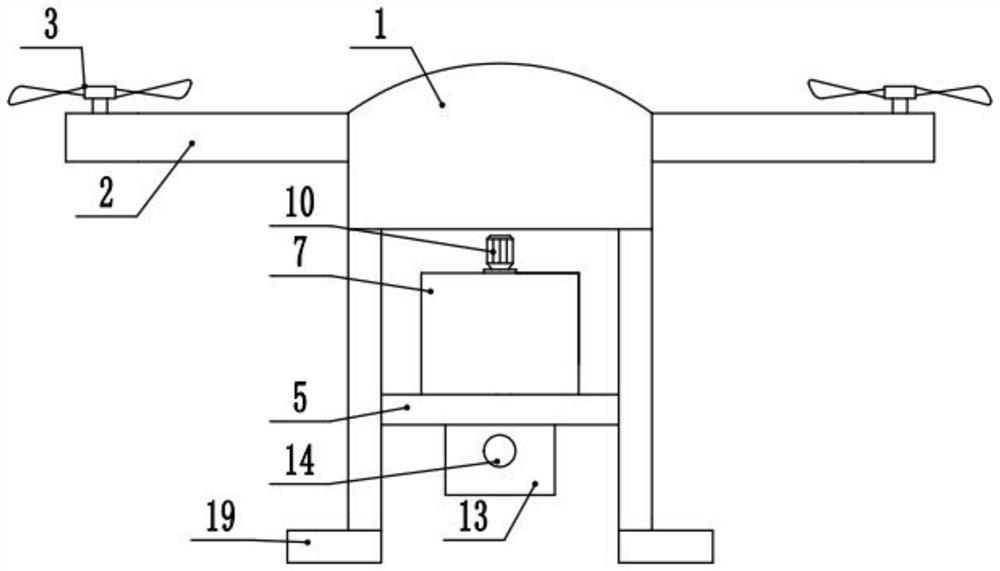

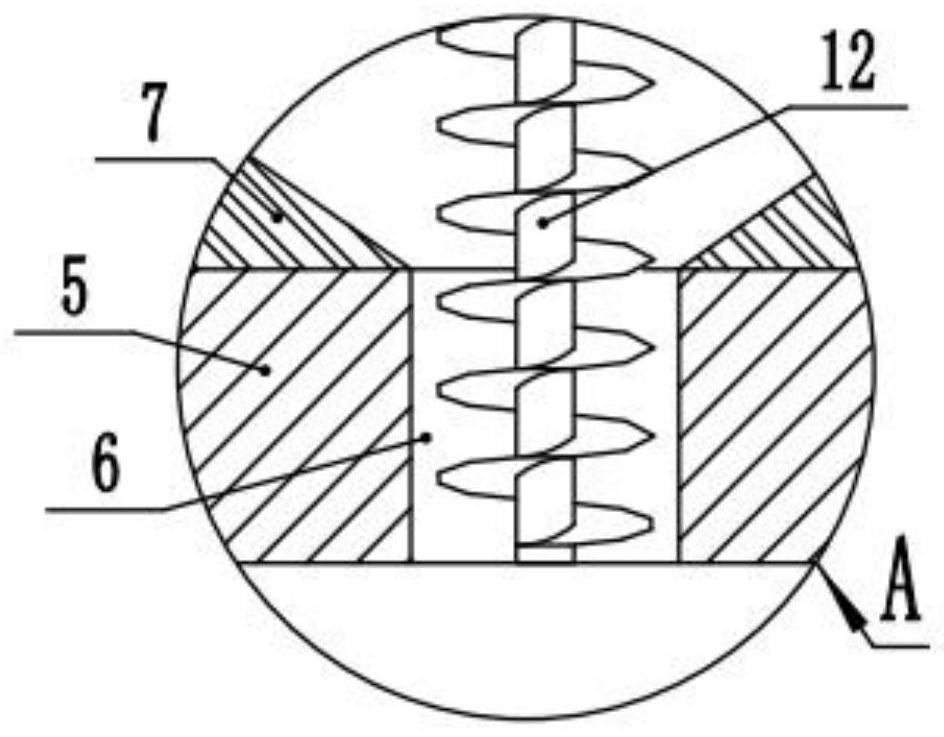

[0032] Please refer to the attached Figure 1-7 , a kind of unmanned aerial vehicle with spiral feeding and seeding mechanism provided by the present invention comprises an unmanned aerial vehicle body 1, and the left and right ends of the unmanned aerial vehicle main body 1 are all symmetrically provided with connecting arms 2 front and rear, and the four connecting arms 2 are far away from unmanned One end of the machine body 1 is provided with a wing 3, and the four corners of the bottom of the drone body 1 are fixedly connected with a bracket 4, and the middle positions of the four brackets 4 are horizontally fixedly connected with a bearing plate 5, and the center

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap