Double-sided photovoltaic module and manufacturing method

A technology of photovoltaic modules and manufacturing methods, which is applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems that double-sided photovoltaic modules are difficult to be widely used, the power generation is not significant, and the manufacturing cost is increased, etc., and achieve strong light transmission effect , The effect of increasing the amount of sunlight and increasing the power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The core of the present invention is to disclose a double-sided photovoltaic module, so that the double-sided photovoltaic module can be applied to a wider range of scenarios.

[0042] Another core of the present invention is to provide a method for manufacturing the above-mentioned double-sided photovoltaic module.

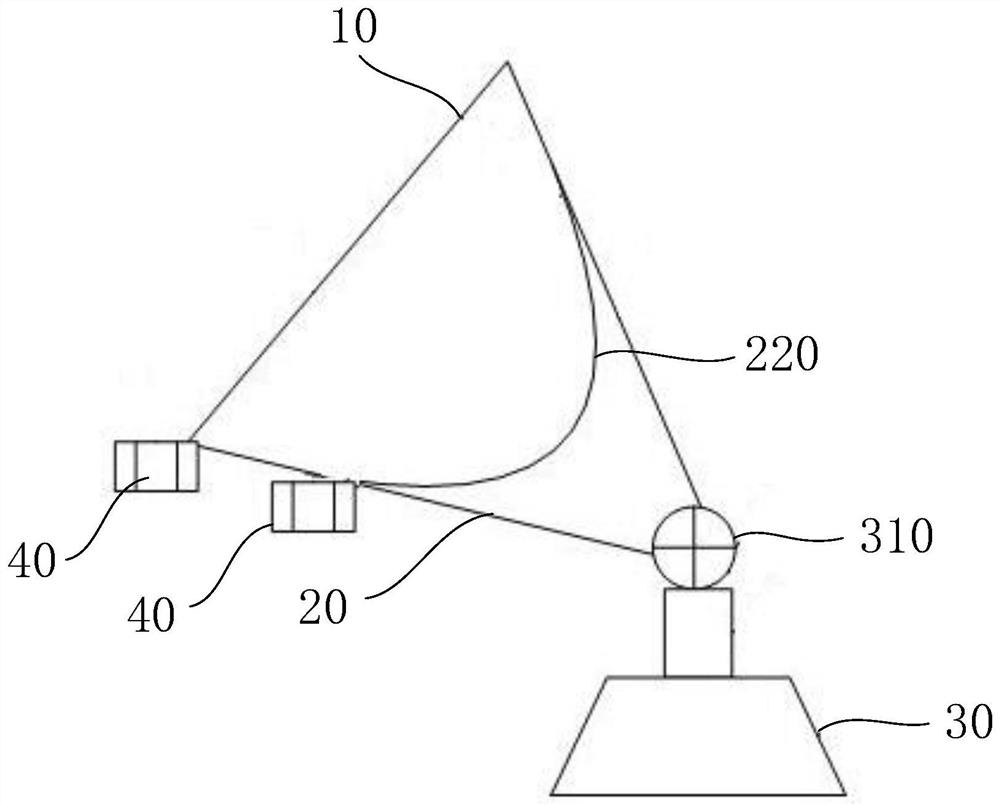

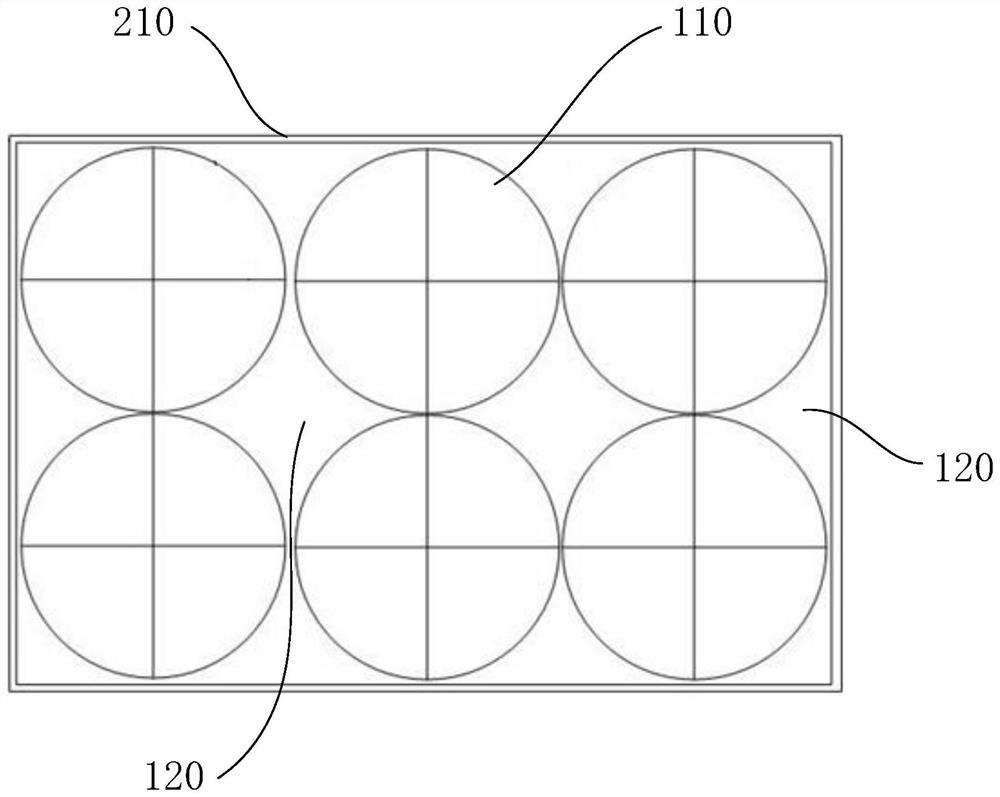

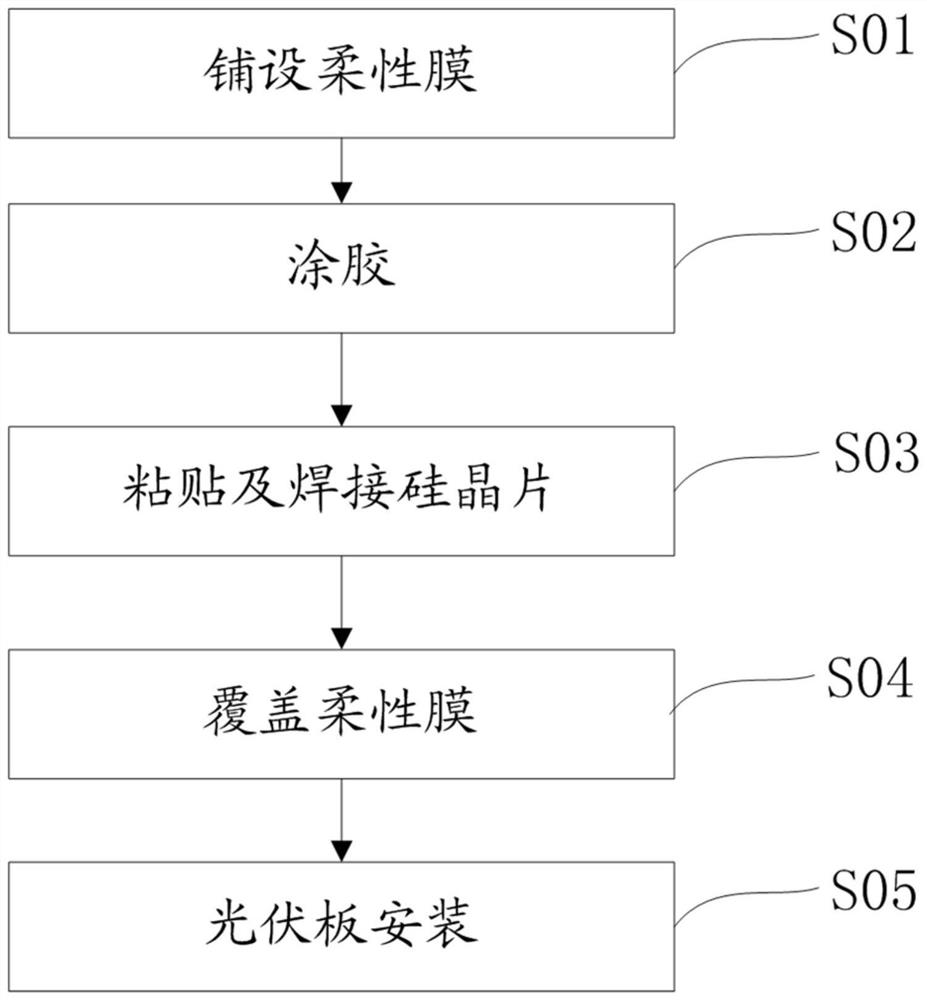

[0043] Such as figure 1 As shown, the photovoltaic assembly provided by the present invention includes a photovoltaic panel 10 and a support 20, wherein the photovoltaic panel 10 includes a plurality of silicon wafers 110 arranged inside the photovoltaic panel 10 to receive light on both sides for photovoltaic power generation, and the plurality of silicon wafers 110 Connect in series to transmit the power generation of each silicon wafer 110. The multiple silicon wafers 110 are circular, and the combination of multiple circular silicon wafers 110 makes the photovoltaic panel 10 have a light-transmitting area 120, so that the photovoltaic panel 10 is trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap