Optimization method of laser plasma extreme ultraviolet light source target material

A technology of laser plasma and extreme ultraviolet light source, applied in the direction of microlithography exposure equipment, optics, optomechanical equipment, etc., to achieve the effect of improving laser conversion efficiency, target material utilization rate and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose and technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] The invention provides a method for optimizing the target material of a laser plasma extreme ultraviolet light source. The method comprises: growing a tin film on a target substrate that generates laser plasma by means of electron beam evaporation to form a solid film target of limited mass Instead of a solid tin target, the amount of tin consumed by a single laser action is controlled by controlling the thickness of the tin layer. By controlling the amount of tin in the thin film target, when the laser interacts with the target to generate plasma, the efficiency of extreme ultraviolet light generation is optimized and the generation of debris is reduced.

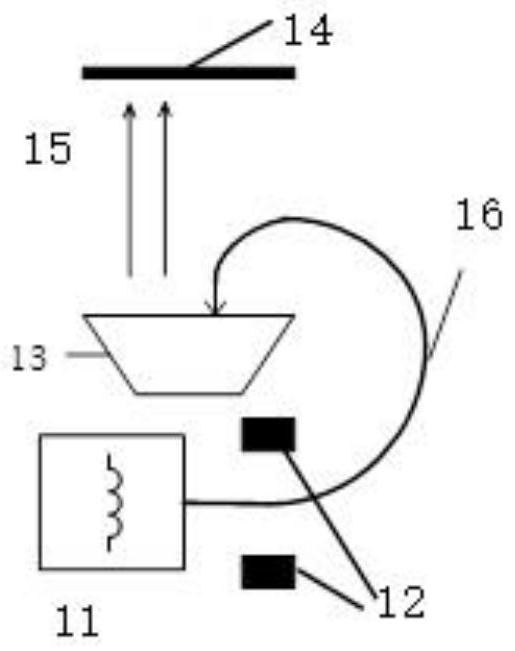

[0019] figure 1 Shown is the thin film target production equipment used in the embodiment of the present inv

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap