Reaction disc and reagent disc combined device

A combination device and reaction plate technology, which is applied in the field of medical equipment and chemiluminescence immunoassay analyzers, can solve the problems of low detection efficiency, large space occupation, and complex structure, and achieve the effects of high detection efficiency, increased speed, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

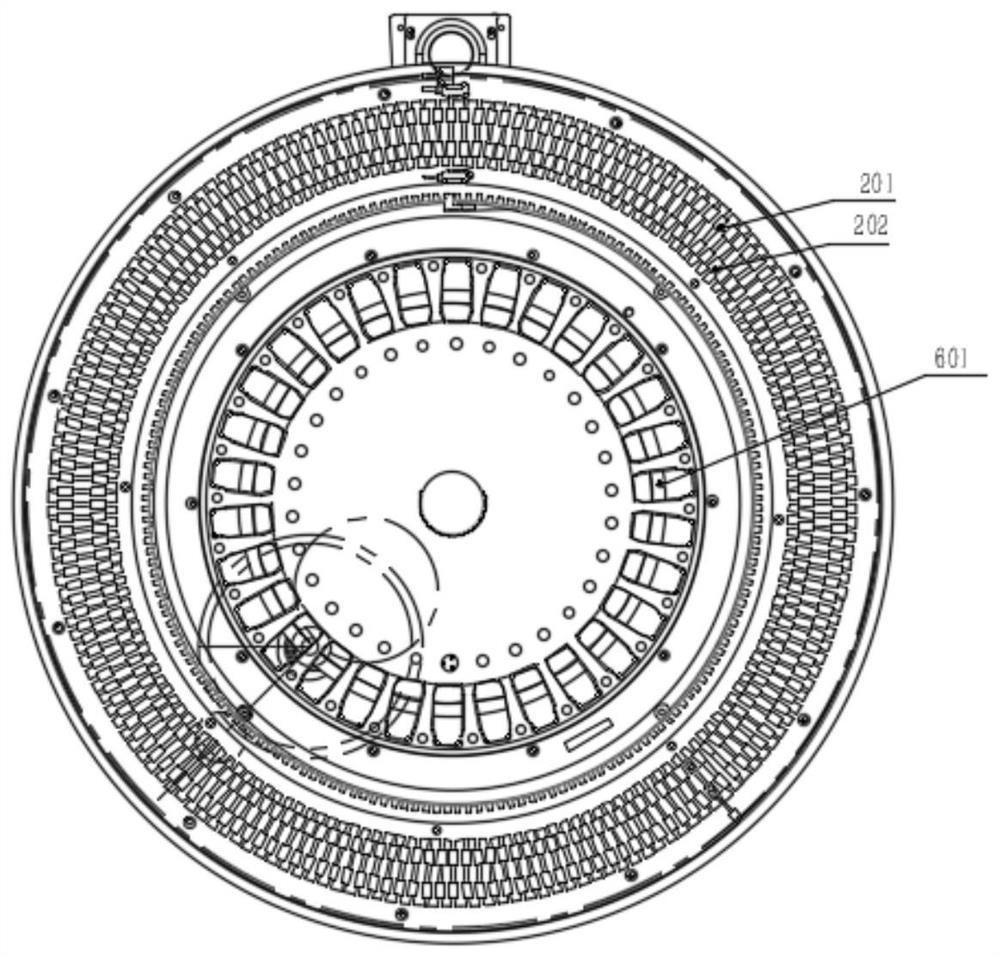

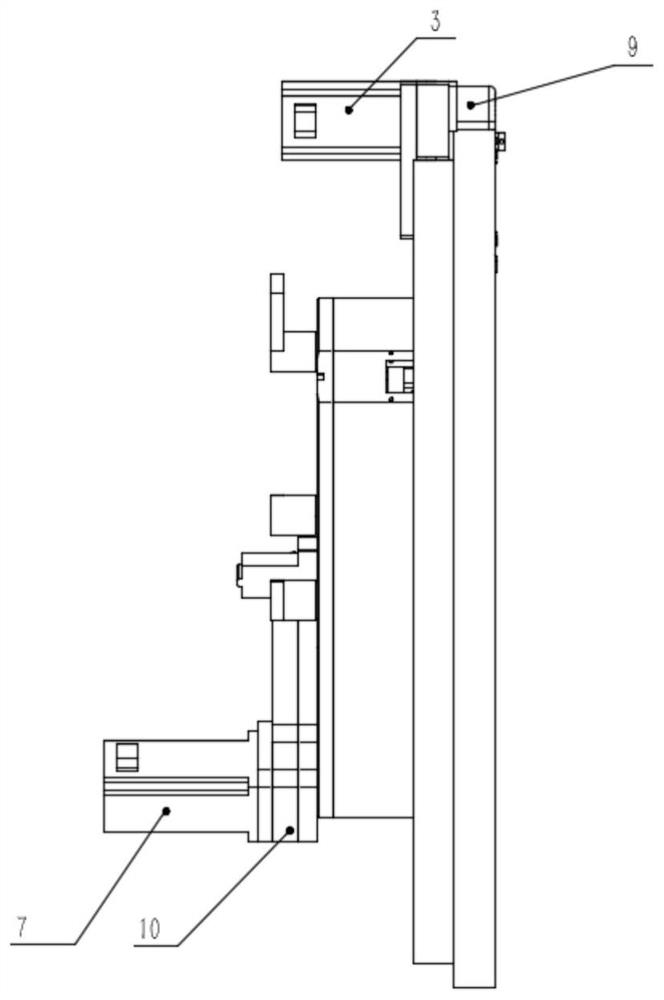

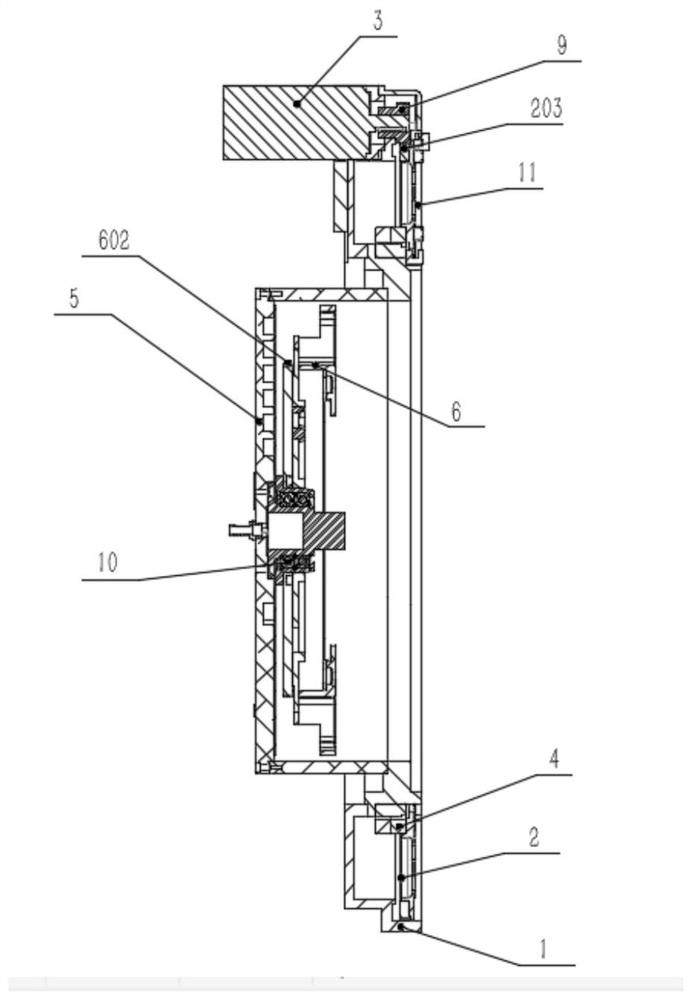

[0039] This embodiment provides a combination device of reaction tray and reagent tray, such as figure 1 , figure 2 and image 3 As shown, including: reaction disk 1, reaction disk rotating plate 2, reaction disk motor 3, reaction disk bearing 4, reagent disk 5, reagent rack 6, reagent disk motor 7, reagent disk bearing 8, gear set A 9, gear set B10, reaction tray cover plate 11; reaction tray rotating plate 2 is provided with outer ring reaction cup groove 201, inner ring reaction cup groove 202 and gear tooth X 203, and reagent rack 6 is provided with reagent cup groove 601 and gear tooth Y 602 ;

[0040] Wherein, the reaction disk motor 3 is fixedly installed on the reaction disk 1, the reaction disk rotating plate 2 and the reaction disk bearing 4 are located in the reaction disk 1, the inner ring of the reaction disk bearing 4 is fixedly installed on the reaction disk 1, and the reaction disk rotating plate 2 It is fixedly connected with the outer ring of the reaction di

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap