In-situ wire changing device and method for micro electrolytic wire cutting

An electrolytic wire, in-situ technology, applied in accessories, electric processing equipment, electrochemical processing equipment, etc., can solve the problem of time-consuming electrode wire installation, time-consuming electrode wire disassembly, installation and adjustment, and electrode wire diameter easily broken. and other problems to achieve the effect of improving processing efficiency, simplifying the replacement process, and replacing quickly and efficiently.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

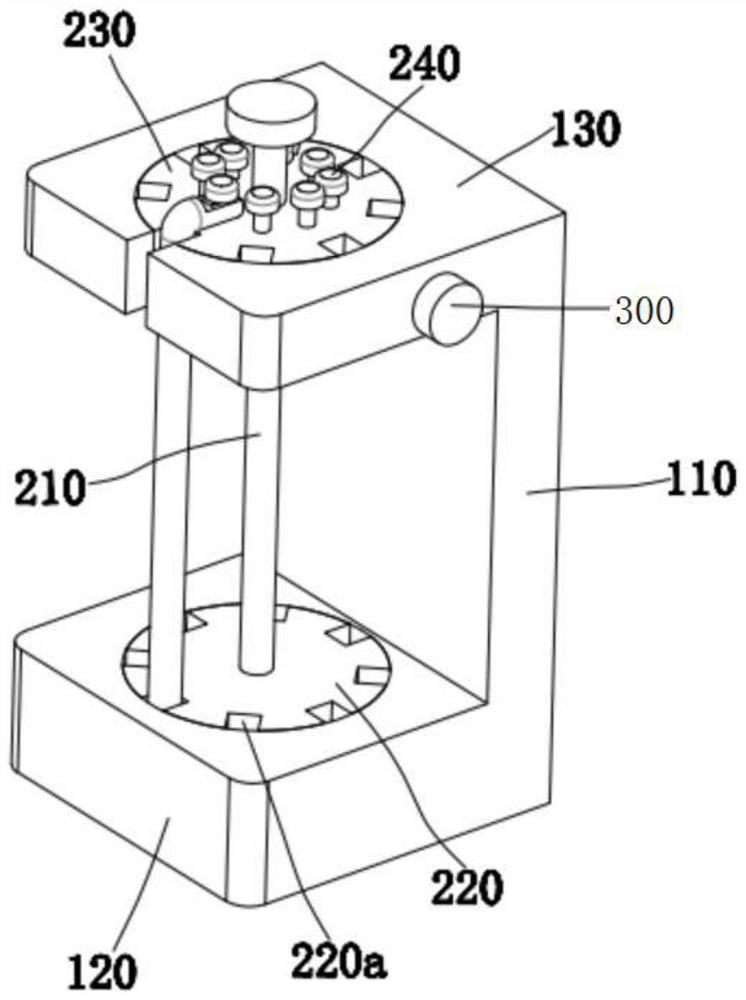

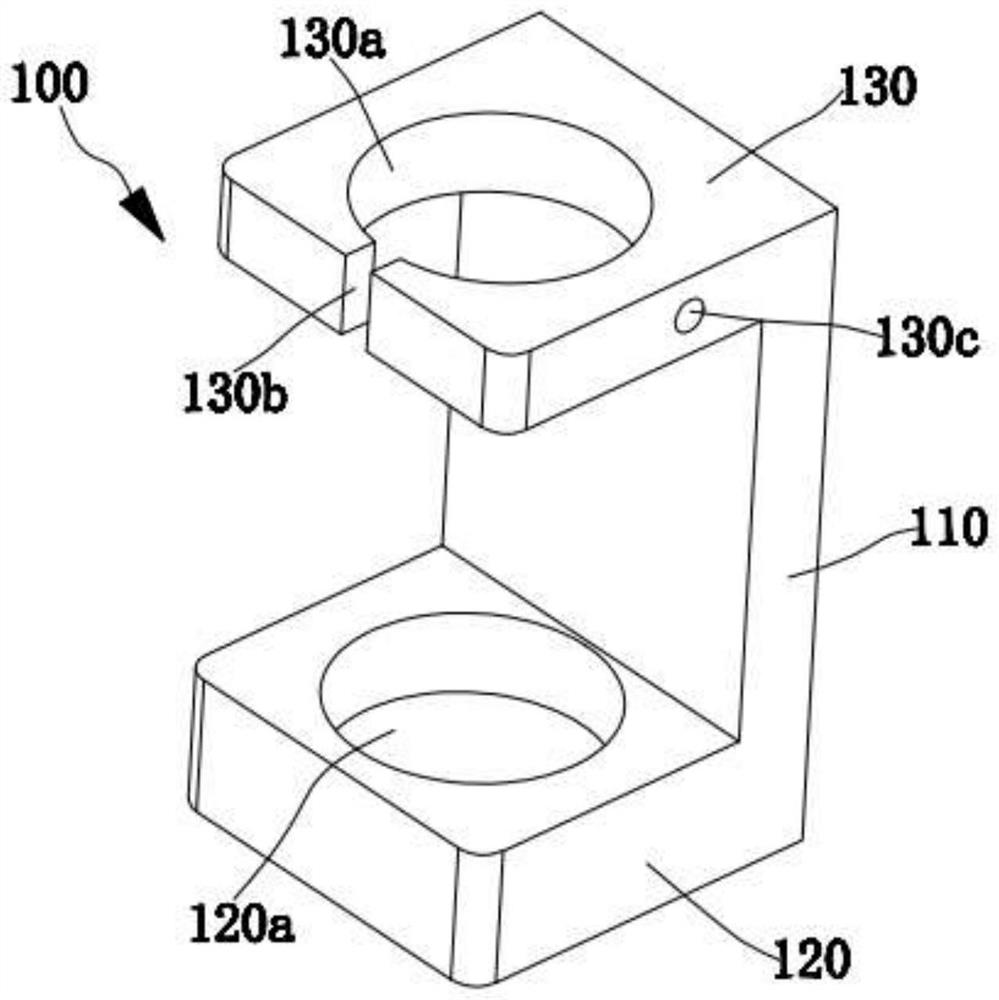

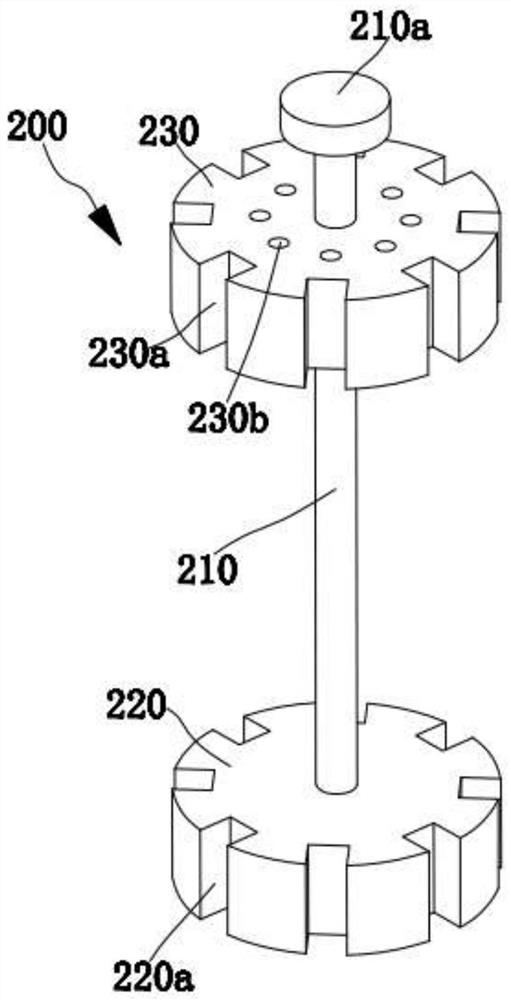

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] Secondly, the present invention is described in detail in conjunction with schematic diagrams. When describing the implementation of the present invention in detail, for the convenience of explanation, the cross-sectional view showing the device structure will not be partially enlarged according to the general scale, and the schematic diagram is only an example, and it should not be limited here. The protection scope of the present invention. In addition, the three-dimensional space dimensions of length, width and depth should be included in actual production.

[0027] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the prese

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap