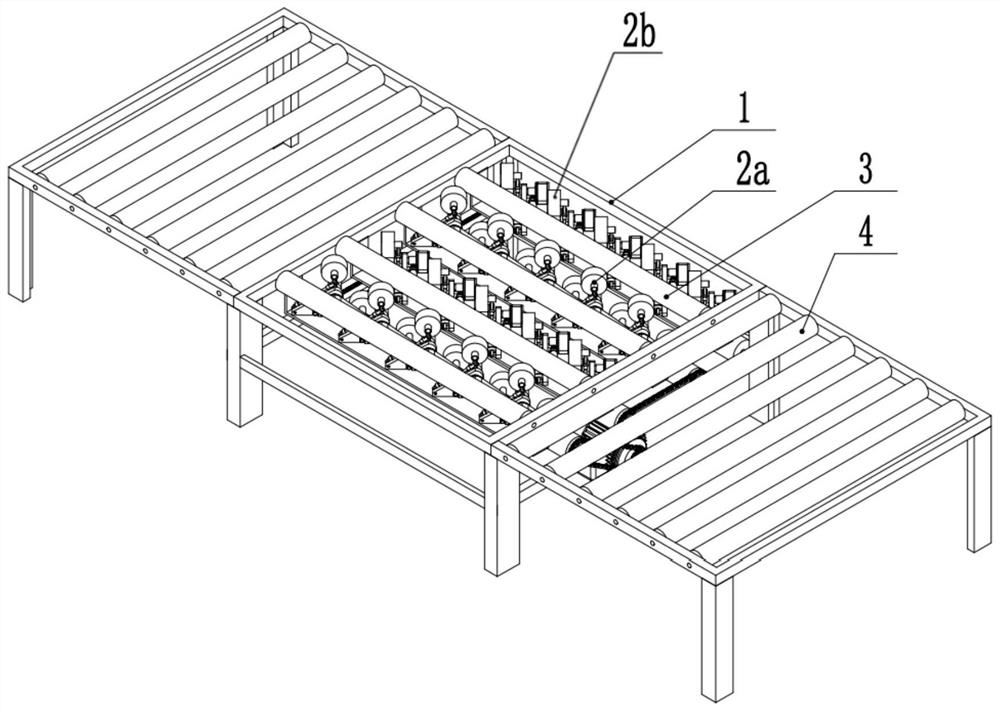

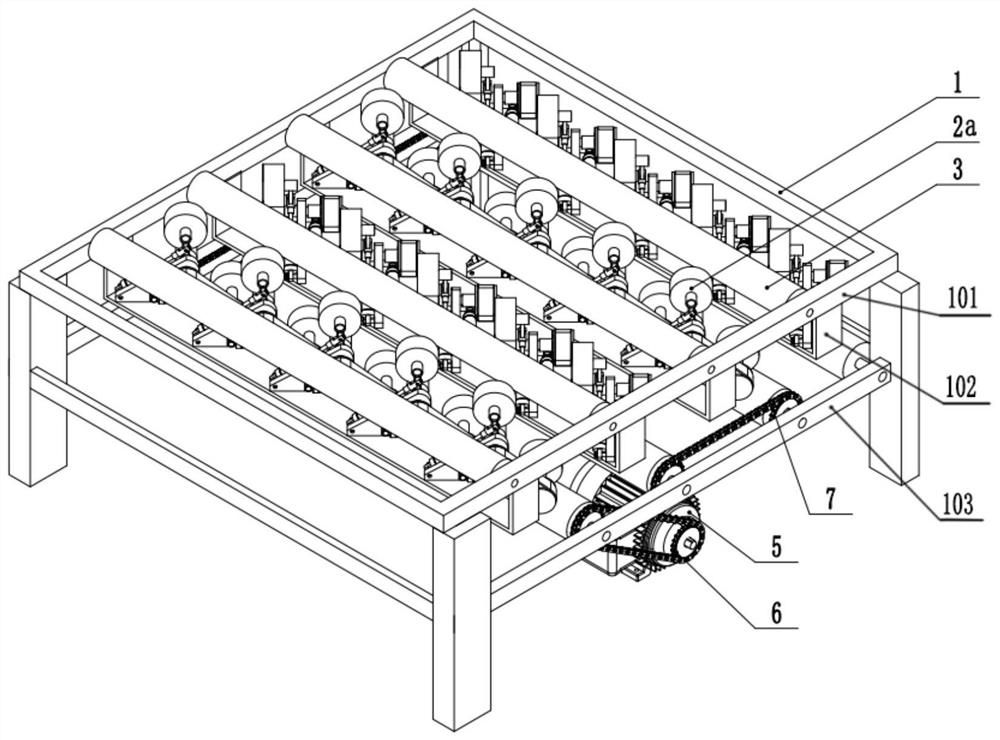

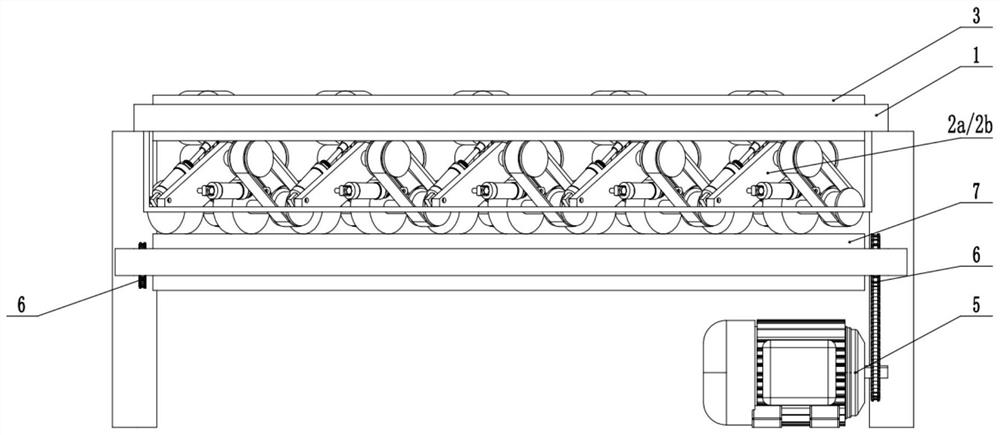

Single-drive roller type automatic sorting machine

An automatic sorting machine and automatic sorting technology, applied in the direction of sorting, etc., can solve the problems of complex mechanical mechanism, complex installation, and high parts processing requirements, and achieve simple mechanical structure, high sorting efficiency, and reduced swing mechanism Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the embodiments and accompanying drawings. Here, the exemplary embodiments of the present invention and their descriptions are used to explain the present invention, but not to limit the present invention.

[0029] Here, it should also be noted that, in order to avoid obscuring the present invention due to unnecessary details, only the structures and / or processing steps closely related to the solution according to the present invention are shown in the drawings, and the related structures and / or processing steps are omitted. Other details not relevant to the present invention.

[0030] It should be emphasized that the term "comprising / comprising" when used herein refers to the presence of a feature, element, step or component, but does not exclude the presence or addition of one or more

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap