Kitchen waste crushing and squeezing all-in-one machine

A kitchen waste and all-in-one machine technology, which is applied to the removal of solid waste, chemical instruments and methods, transportation and packaging, etc., can solve problems such as poor crushing effect, foul smell, and easy deterioration and decay of kitchen waste, so as to achieve an improvement Crushing effect, effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

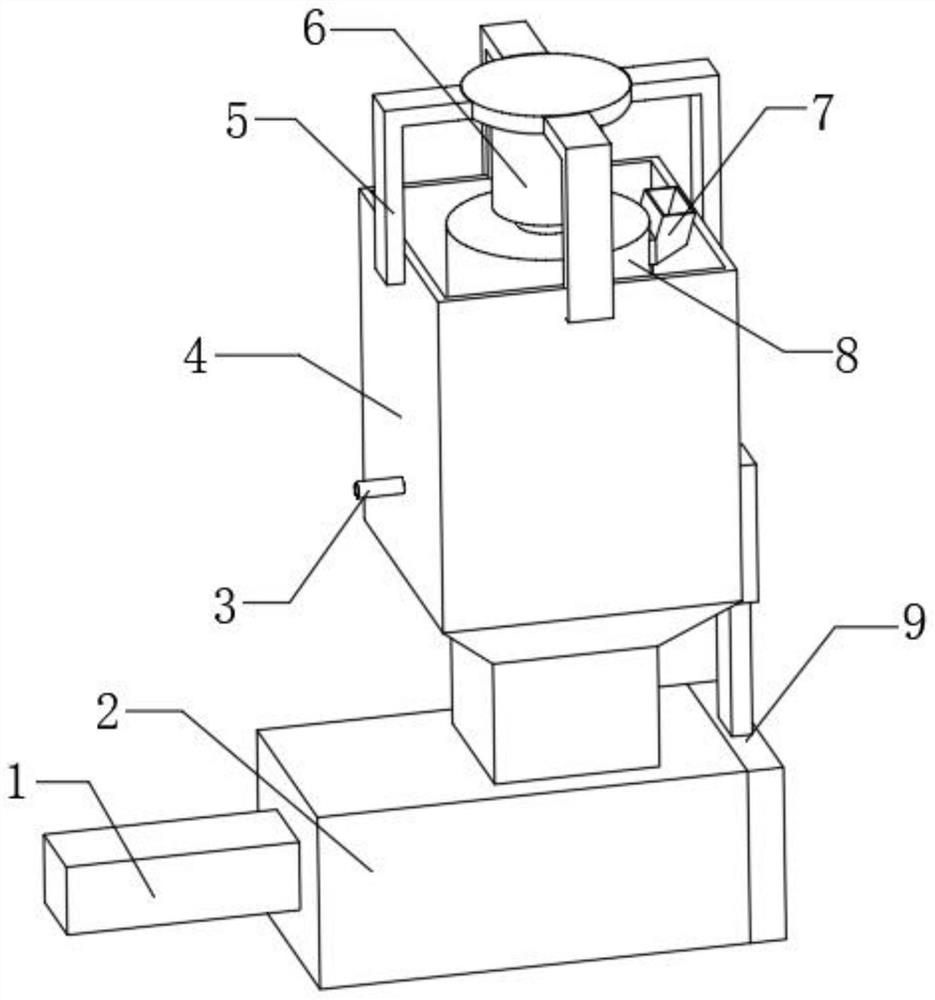

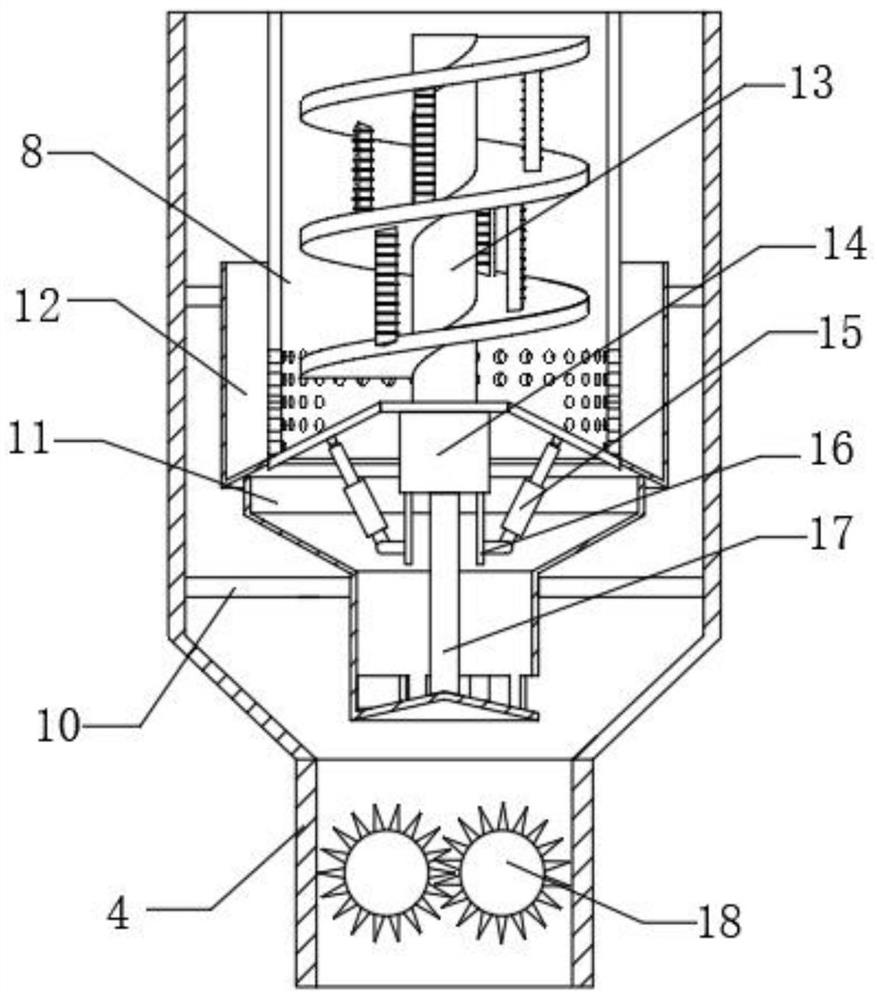

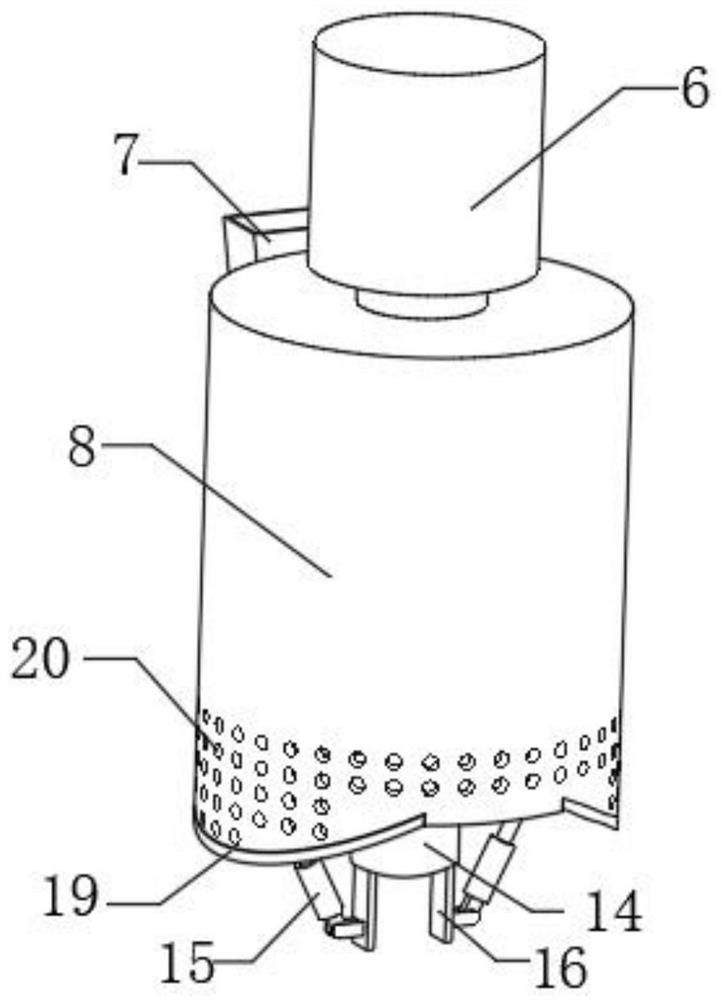

[0031] refer to Figure 1-Figure 5 , an integrated machine for crushing and pressing of kitchen waste, comprising a casing 4, a partition plate 10 is fixedly connected inside the casing 4, and an oil-water separation cylinder 8 is arranged directly above the separation plate 10, and an outer wall above one side of the oil-water separation cylinder 8 is provided with A centrifugal motor 6 is provided on the top outer wall of the oil-water separation cylinder 8, and a fixed bracket 5 is fixedly connected to the top outer wall of the centrifugal motor 6. The fixing bracket 5 is fixedly connected to the upper outer wall of the casing 4, and the bottom of the oil-water separation cylinder 8 is rotatably connected with a rotating shaft 13 , and the bottom outer wall of the rotating shaft 13 is provided with a rotary motor 14, and the outer walls on both sides of the bottom of the rotary motor 14 are fixedly connected with a fixed plate 16, the oil and water are separated from the bottom

Embodiment 2

[0036] refer to Figure 1-Figure 7 , an integrated machine for crushing and pressing of kitchen waste, comprising a casing 4, a partition plate 10 is fixedly connected inside the casing 4, and an oil-water separation cylinder 8 is provided directly above the separation plate 10, and an outer wall above one side of the oil-water separation cylinder 8 is provided with A centrifugal motor 6 is provided on the top outer wall of the oil-water separation cylinder 8, and a fixed bracket 5 is fixedly connected to the top outer wall of the centrifugal motor 6. The fixing bracket 5 is fixedly connected to the upper outer wall of the casing 4, and the bottom of the oil-water separation cylinder 8 is rotatably connected with a rotating shaft 13 , and the bottom outer wall of the rotating shaft 13 is provided with a rotary motor 14, and the outer walls on both sides of the bottom of the rotary motor 14 are fixedly connected with a fixed plate 16, the oil and water are separated from the bottom

Embodiment 3

[0044] refer to Figure 1-Figure 9 , an integrated machine for crushing and pressing of kitchen waste, comprising a casing 4, a partition plate 10 is fixedly connected inside the casing 4, and an oil-water separation cylinder 8 is provided directly above the separation plate 10, and an outer wall above one side of the oil-water separation cylinder 8 is provided with A centrifugal motor 6 is provided on the top outer wall of the oil-water separation cylinder 8, and a fixed bracket 5 is fixedly connected to the top outer wall of the centrifugal motor 6. The fixing bracket 5 is fixedly connected to the upper outer wall of the casing 4, and the bottom of the oil-water separation cylinder 8 is rotatably connected with a rotating shaft 13 , and the bottom outer wall of the rotating shaft 13 is provided with a rotary motor 14, and the outer walls on both sides of the bottom of the rotary motor 14 are fixedly connected with a fixed plate 16, the oil and water are separated from the bottom

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap