Silicon-based negative electrode material and preparation method and application thereof

A silicon-based negative electrode material, silicon material technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of short cycle life, low initial efficiency of pre-lithiated silicon-based negative electrode materials, etc., to achieve long cycle life, high First coulombic efficiency and reversible capacity, the effect of high first coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

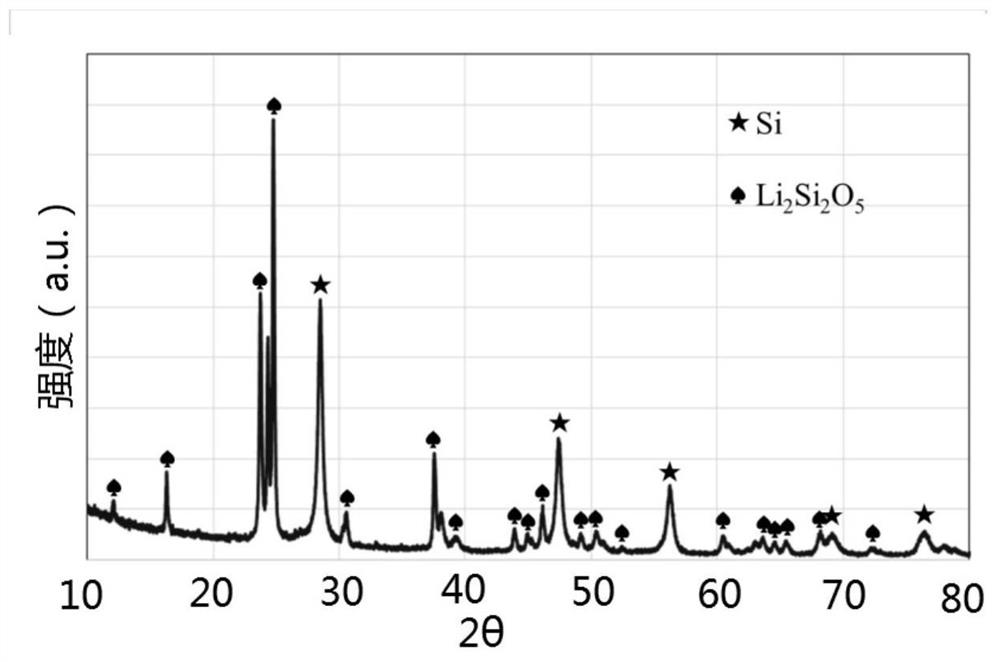

Embodiment 1

[0047] This embodiment provides a silicon-based negative electrode material, the raw material of which includes 2 g of tetrabutylphosphine bis(trifluoromethanesulfonyl)imide salt (C 18 H 36 F 6 NO 4 PS 2), 1 g of lithium foil and 20 g of commercially available silicon oxide negative electrode material (SiO / C, the carbon content in the negative electrode material is 4.5 wt%).

[0048] The preparation method of the above-mentioned silicon-based negative electrode material comprises the following steps,

[0049] In an argon-protected glove box, each raw material was put into the ball milling jar of a low-temperature planetary ball mill according to the above-mentioned quality, and ball-milled for 4 hours by means of alternating forward and reverse ball milling to obtain a pre-lithiated silicon-based negative electrode material; wherein, the glove box Medium H 2 O and O 2 The content is less than 0.1ppm; the ratio of ball to material is 20:1, the rotation speed of the ball mi

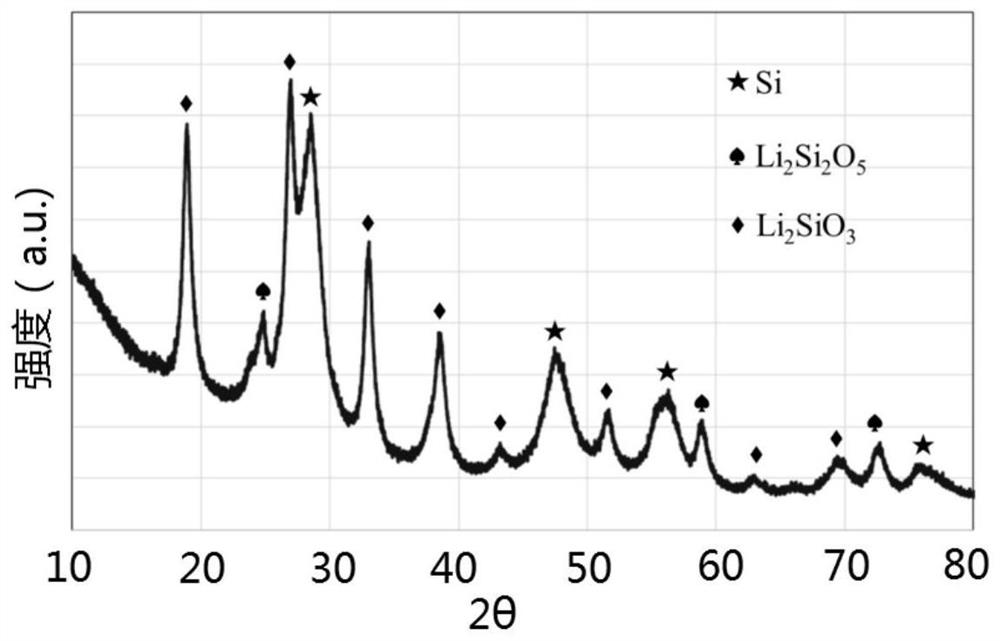

Embodiment 2

[0052] This embodiment provides a silicon-based negative electrode material, the raw material of which includes 2 g of tetrabutylphosphine bis(trifluoromethanesulfonyl)imide salt (C 18 H 36 F 6 NO 4 PS 2 ), 1.5 g of lithium foil and 20 g of commercially available silicon oxide negative electrode material (same as Example 1).

[0053] The preparation method of the above-mentioned silicon-based negative electrode material comprises the following steps,

[0054] In an argon-protected glove box, each raw material was put into the ball milling jar of a low-temperature planetary ball mill according to the above-mentioned quality, and ball-milled for 4 hours by means of alternating forward and reverse ball milling to obtain a pre-lithiated silicon-based negative electrode material; wherein, the glove box Medium H 2 O and O 2 The content is less than 0.1ppm; the ratio of ball to material is 20:1, the rotation speed of the ball mill is 400rpm, and the time of forward and reverse alt

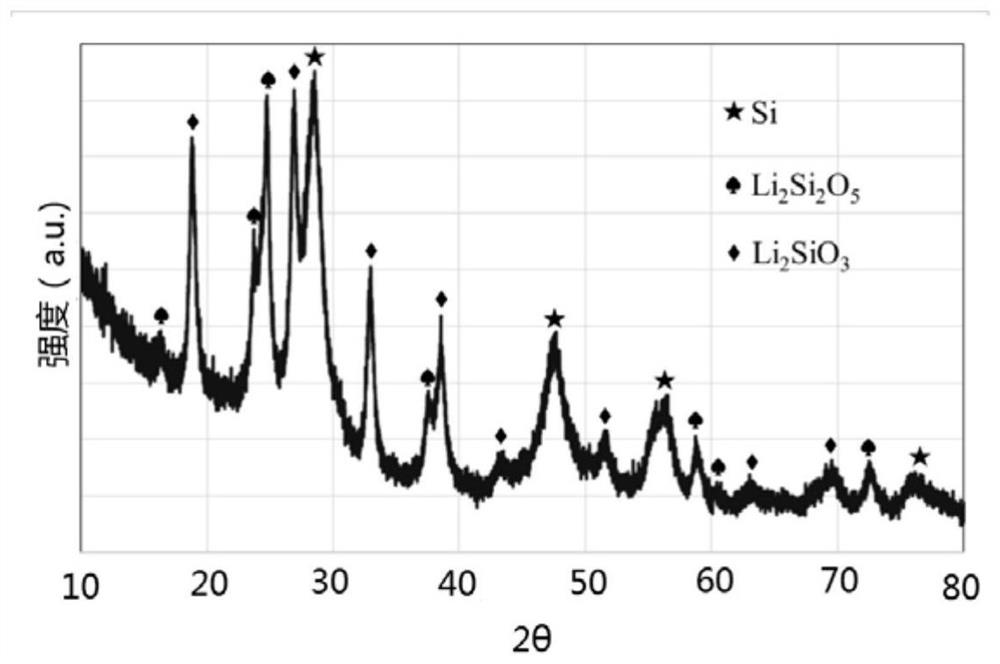

Embodiment 3

[0057] This embodiment provides a silicon-based negative electrode material, the raw material of which includes 2 g of tetrabutylphosphine bis(trifluoromethanesulfonyl)imide salt (C 18 H 36 F 6 NO 4 PS 2 ), 2 g of lithium foil and 20 g of commercially available silicon oxide negative electrode material (same as Example 1).

[0058] The preparation method of the above-mentioned silicon-based negative electrode material comprises the following steps,

[0059] In an argon-protected glove box, each raw material was put into the ball milling jar of a low-temperature planetary ball mill according to the above-mentioned quality, and ball-milled for 4 hours by means of alternating forward and reverse ball milling to obtain a pre-lithiated silicon-based negative electrode material; wherein, the glove box Medium H 2 O and O 2 The content is less than 0.1ppm; the ratio of ball to material is 20:1, the rotation speed of the ball mill is 400rpm, and the time of forward and reverse alter

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap