Automatic charging controlling device of cement paste stirrer

A technology of automatic feeding and control device, applied in mixing operation control device, clay preparation device, raw material supply device for sale, etc., can solve the problems of shortened service life of mixer, difficulty in feeding material at any time, waste of cement, etc. Improve production efficiency and stir well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. These embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

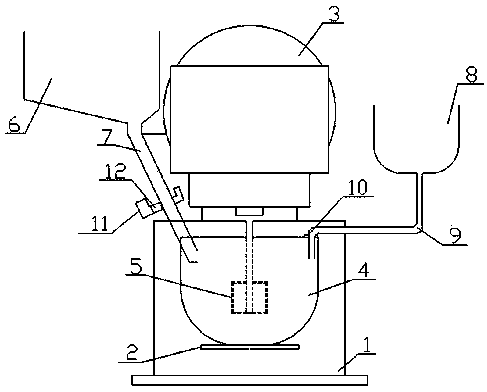

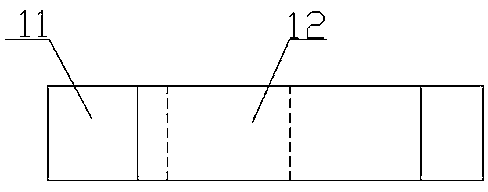

[0013] Such as figure 1 The shown automatic feeding control device of a cement slurry mixer includes a mixer main body 1, a fixed pallet 2, a motor transmission device 3, a stirring pot 4 and a stirring blade 5, the stirring pot 4 is installed on the fixed pallet 2, and the stirring blade 5 is installed on the motor transmission device 3, a lime storage cup 6 is installed on one side of the main body of the mixer, and the lime storage cup 6 is connected with one end of the ash injection pipeline 7, and the other end of the ash injection pipeline 7 is located in the mixing pot 4, and the main body of the mixer The other side of 1 is eq...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap