Anti-dust and mite viscose filament rayon fiber

A viscose filament and dust mite technology, applied in the field of artificial filament, can solve the problems of complex production process, insufficient drug effect, and difficulty in industrial implementation and promotion, and achieve simple process, long-lasting washable drug effect, and durability lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions of the present invention will be further specifically described below through examples.

[0013] Example.

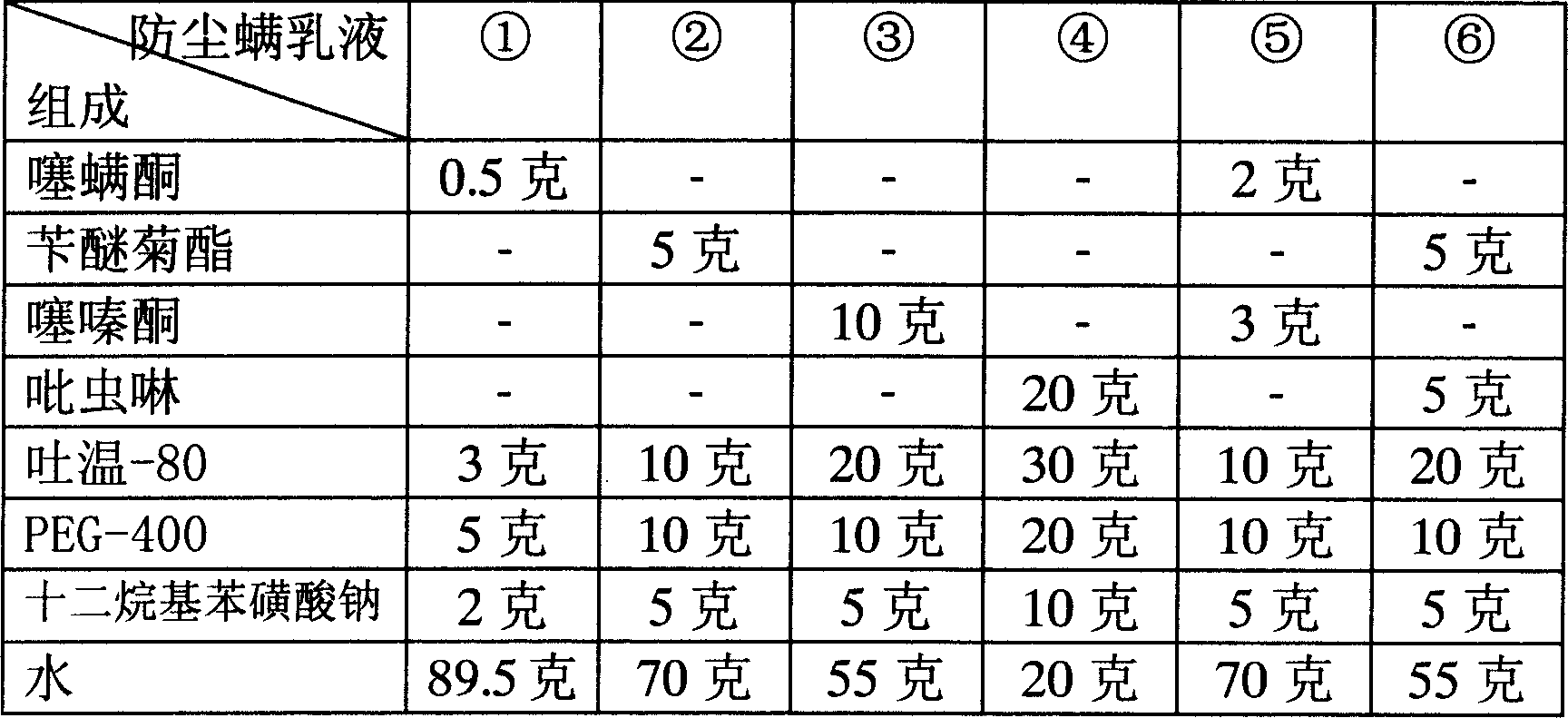

[0014] Step 1: Prepare the lotion. The anti-dust mite additive of the present invention has 4 kinds, is dissolved in Tween-80 (sorbitan fatty acid ester polyoxyethylene ether), PEG-400 (polyethylene glycol-400), dodecylbenzenesulfonate respectively Sodium acid (alkyl aryl sulfonate) and water, fully stirred into a uniform emulsion, its formula is shown in Table 1.

[0015] Table 1 The formula table of the anti-dust mite emulsion of the present invention

[0016]

[0017] The second step: blending and spinning. Production of anti-mite viscose filament fibers on a spinning machine in a viscose filament factory. The anti-dust mite emulsion of the present invention is blended online at high speed with viscose dope size filtered through three channels, and then spun after vacuum defoaming. The silk cake after spinning is processed by rinsin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap