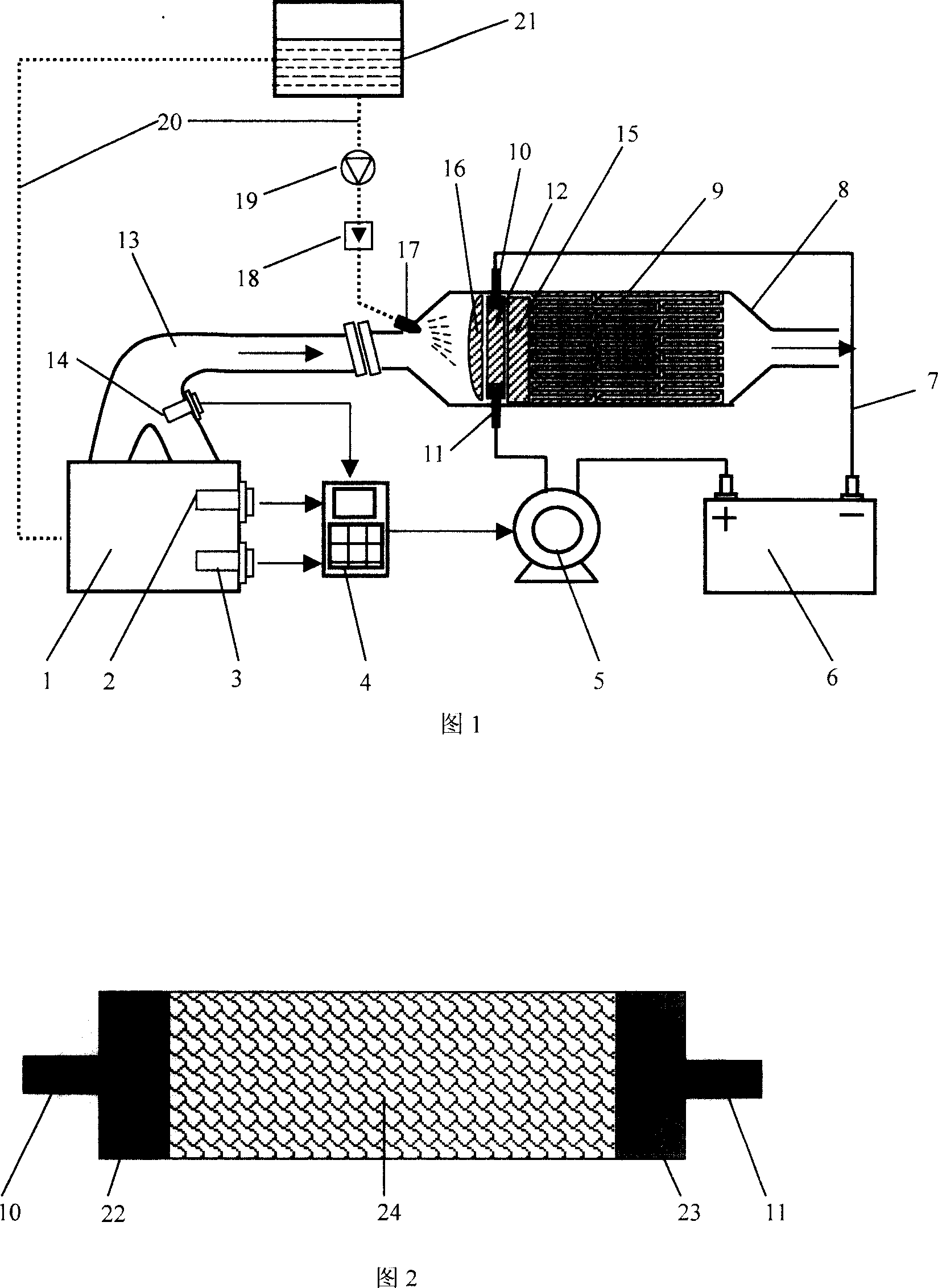

Wall-flow type filtering-regeneration device for particulates in exhaust gas from diesel vehicle

A regeneration device and particulate filter technology, which is applied to exhaust devices, mufflers, engine components, etc., can solve problems such as extreme temperature unevenness and bursting, and achieve long service life, strong thermal shock resistance, and uniform temperature distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0052] Example 1

[0053] ① Take the conductive silicon carbide foam ceramic 130×40×20mm, soak it in a 3M NaOH solution for 8 minutes to remove the oil and other impurities on the surface, then wash it with water, and then dry it in an air atmosphere at 120°C for 2 hours;

[0054] ②Braze two stainless steel columns with a diameter of 6mm on the silicon carbide ceramic electrode bases located at the two ends of the conductive silicon carbide foam ceramic described in ① as electrodes connected to the wires. An electric heating heating element unit has been prepared;

[0055] ③Follow the steps from ① to ② above, make two electric heating heating element units, and then connect the two electric heating heating element units by welding metal plates on the metal electrode and weld them together in parallel to obtain a complete electric heating heating element. The resistance of the electric heating element is 50mΩ.

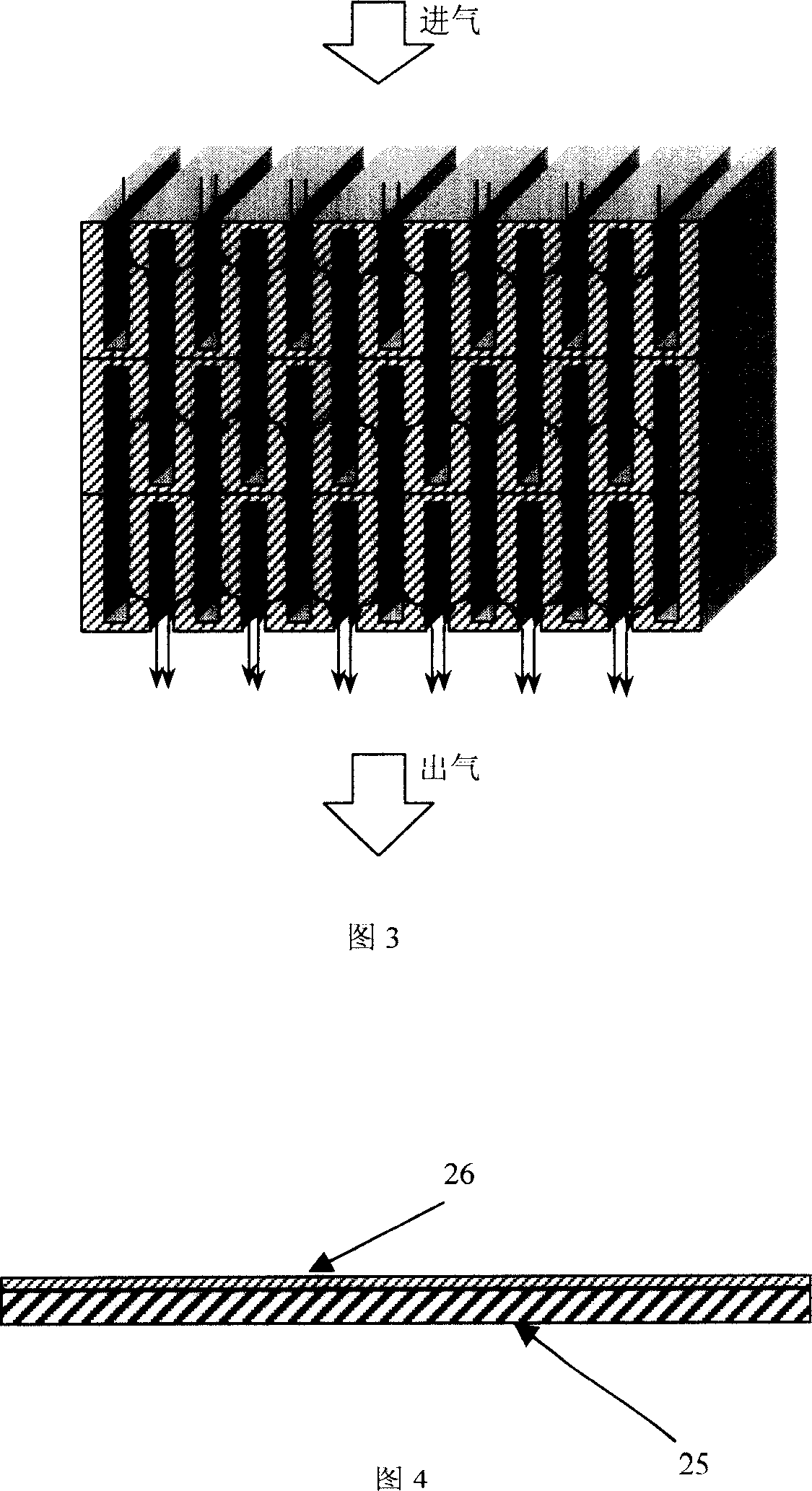

[0056] ④As shown in Figure 3, combine the silicon carbide foam ceramic pl

Example Embodiment

[0060] Example 2

[0061] The difference from Example 1 lies in:

[0062] Before the test, install the wall-flow diesel vehicle exhaust particulate filter-regeneration device at the designated position of the diesel engine exhaust passage to keep the engine running at a high concentration of soot emission with a speed of 2160rpm, a torque of 188Nm, and a power of 42.5kW. The control unit monitors the back pressure sensor signal, and when the back pressure signal is greater than 20 kPa, it is considered that the filter needs to be regenerated. At this time, the control unit turns on the electric heating circuit and is powered by the 12V on-board DC battery. After 5 seconds, it turns on the controllable fuel injection device and injects fuel 5 at a flow rate of 200ml / min upstream of the electric heating element at a frequency of 12 times / min. Each time, 5ml each time, then cut off the power and oil, and turn off the engine.

[0063] After the engine has cooled down, restart the eng

Example Embodiment

[0064] Example 3

[0065] The difference from Example 2 lies in:

[0066] At a flow rate of 200ml / min, the fuel is injected 5 times at a frequency of 12 times / min upstream of the electric heating heating element, each time 10ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap