Heating system for fiber-reinforced thermoplastic feedstock and workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

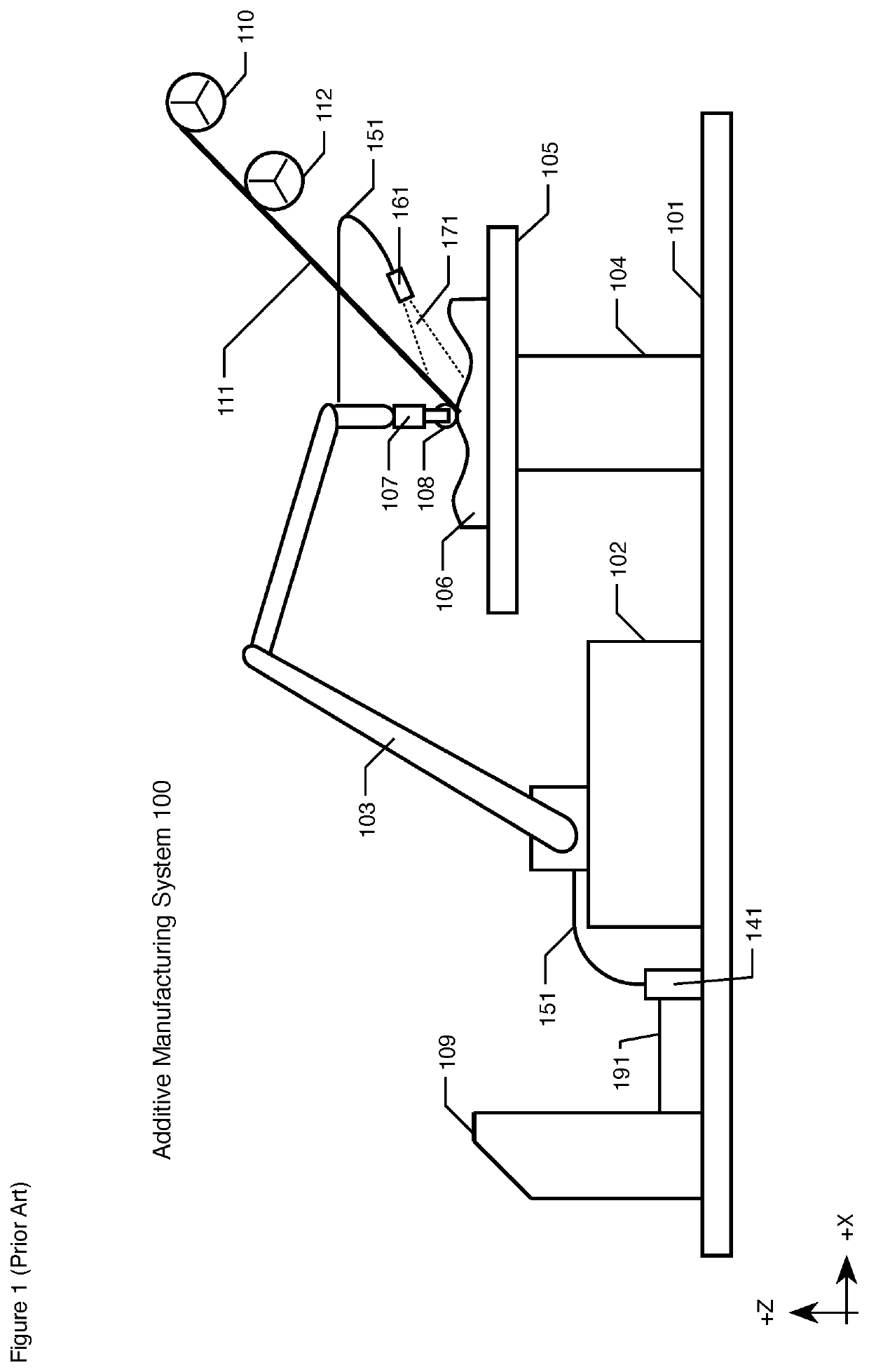

[0092]FIG. 4 depicts an illustration of additive manufacturing system 400 in accordance with the first illustrative embodiment of the present invention. Additive manufacturing system 400 fabricates an article of manufacture by successively depositing segments of fiber-reinforced thermoplastic feedstock (e.g., filament, tape, etc.) onto a workpiece until the article of manufacture is complete.

[0093]Additive manufacturing system 400 comprises: platform 401, robot mount 402, robot 403, build plate support 404, build plate 405, workpiece 406, deposition head 407, tamping tool 408, controller 409, feedstock reel 410, feedstock 411, accumulator 412, force gauge 413, sensor array 415, feedstock laser 441, workpiece laser 442, optical cable 451, optical cable 452, sensor cable 454, optical instrument 461, optical instrument 462, laser beam 471, laser beam 472, feedstock laser control cable 491, and workpiece laser control cable 492, interrelated as shown.

[0094]FIG. 5a depicts a close-up of wor

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap