Methods of preparing maleimide functionalized polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

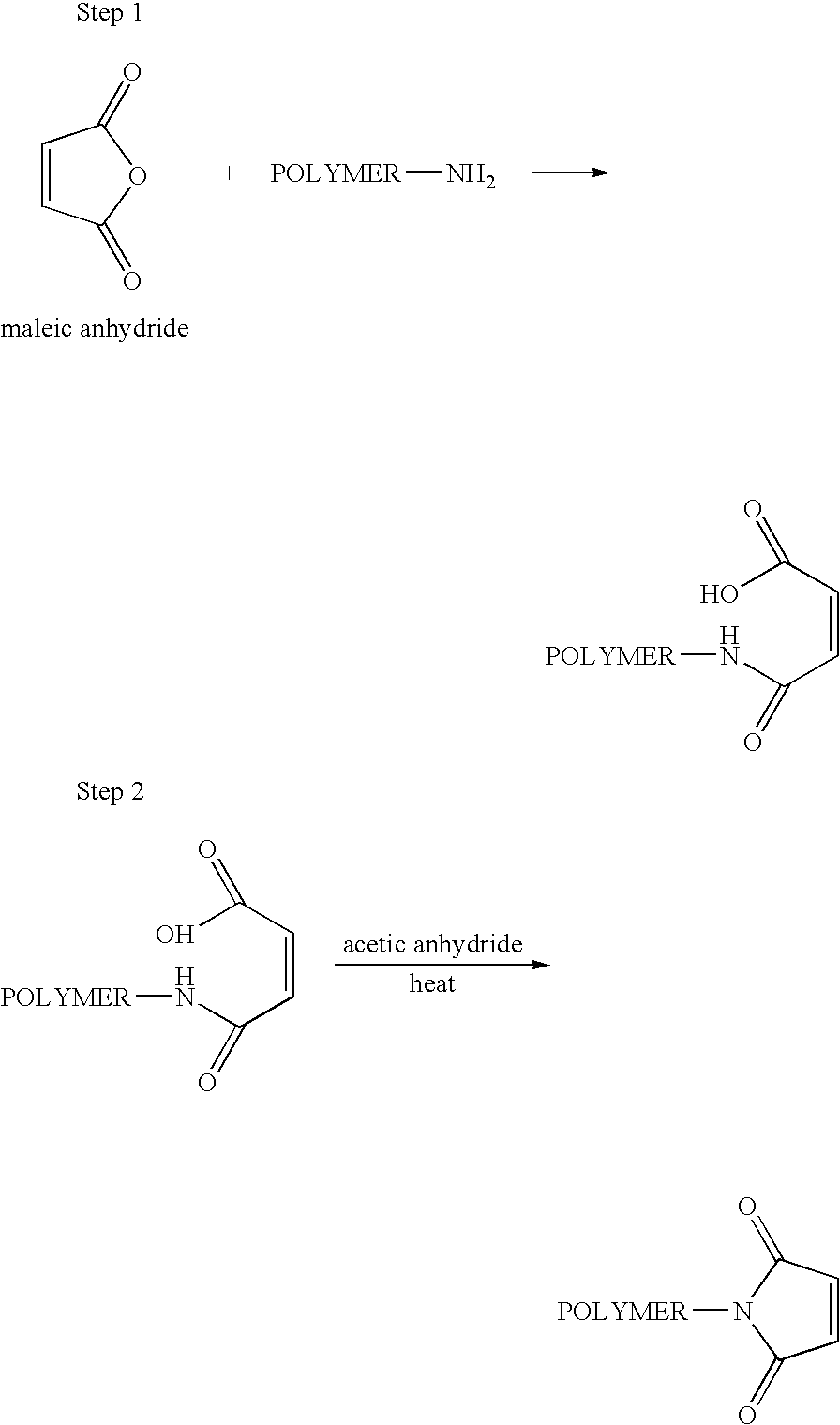

Method used

Image

Examples

example 1

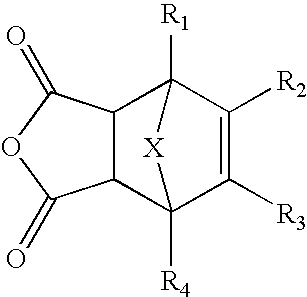

Preparation of 2-Hydroxyethylmaleimide-Furan Adduct (HEMI-A or N-hydroxyethyl exo-3,6-epoxy-1,2,3,6-tetrahydrophthalimide)

[0199]

[0200] To a solution of exo-3,6-epoxy-1,2,3,6-tetrahydrophthalic anhydride (Sigma-Aldrich, St. Louis Mo.; 30.0 g, 0.181 moles) in anhydrous ethyl alcohol (40 mL), a solution of ethanolamine (12.6 g, 0.206 moles) in anhydrous ethyl alcohol (10 mL) was added over a time period of 2 hours to form a mixture. The mixture was then refluxed for about 3.5 hours and was cooled to room temperature and left to stand overnight. The precipitated product that formed during overnight standing was filtered off and washed with 20 mL of anhydrous ethyl alcohol. The collected solid was then dried under reduced pressure giving 18.3 g of white crystals. NMR (d6-DMSO): 2.92 ppm (s, —CH, 2H), 3.41 ppm (m, —CH2CH2—, 4H), 4.77 ppm (bm, —OH, 1H), 5.12 ppm (s, —CH, 2H), 6.55 ppm (s, —CH═CH—, 2H). Purity: ˜100%.

example 2

Preparation of Succinimidyl Carbonate of 2-Hydroxyethylmaleimide-Furan Adduct (HEMI-A-SC)

[0201]

[0202] To a solution of HEMI-A (2.0 g, 0.0095 moles) in anhydrous acetonitrile (30 mL), was added anhydrous pyridine (1.0 mL, 0.0124 moles) and N,N-disuccinimidyl carbonate (DSC, 2.43 g, 0.0095 moles). The resulting mixture was stirred overnight at room temperature under a nitrogen atmosphere. The precipitated product that formed during the overnight reaction was filtered off and washed with 5 mL of acetonitrile. The collected solid was dried under vacuum giving 2.68 g of white crystals. NMR (d6-DMSO): 2.79 ppm (s, —CH2CH2—, succinimide, 2H), 2.96 ppm (s, —CH, 2H), 3.72 ppm (t, —CH2—N, 2H), 4.41 ppm (t, —CH2CH2—N, 2H), 5.15 ppm (s, —CH, 2H), 6.56 ppm (s, —CH═CH—, 2H). Purity: ˜100%.

example 3

Preparation of mPEG(5 KDa)-HEMI-A

[0203]

[0204] To a solution mPEG(5 KDa)-amine (2.0 g, 0.00040 moles) (Nektar Therapeutics, Huntsville Ala.) in anhydrous acetonitrile (30 mL) was added HEMI-A-SC (0.15 g, 0.00043 moles) and triethylamine (0.050 mL) to form a reaction mixture. The reaction mixture was then stirred overnight at room temperature under an argon atmosphere. Next, the solvent was evaporated to dryness. The crude product was then dissolved in methylene chloride and precipitated with ethyl ether at 0° C. The wet product was dried under reduced pressure to yield 1.9 g of the desired product. NMR (d6-DMSO): 2.92 ppm (s, —CH, 2H), 3.08 ppm (q, —OCH2CH2N, 2H), 3.24 ppm (s, —OCH3), 3.51 ppm (s, PEG backbone), 4.00 ppm (t, —CH2(C═O)N, 2H), 5.13 ppm (s, —CH, 2H), 6.55 ppm (s, —CH═CH—, 2H). Substitution of HEMI-A: ˜100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap