Method for controlling soot induced lubricant viscosity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

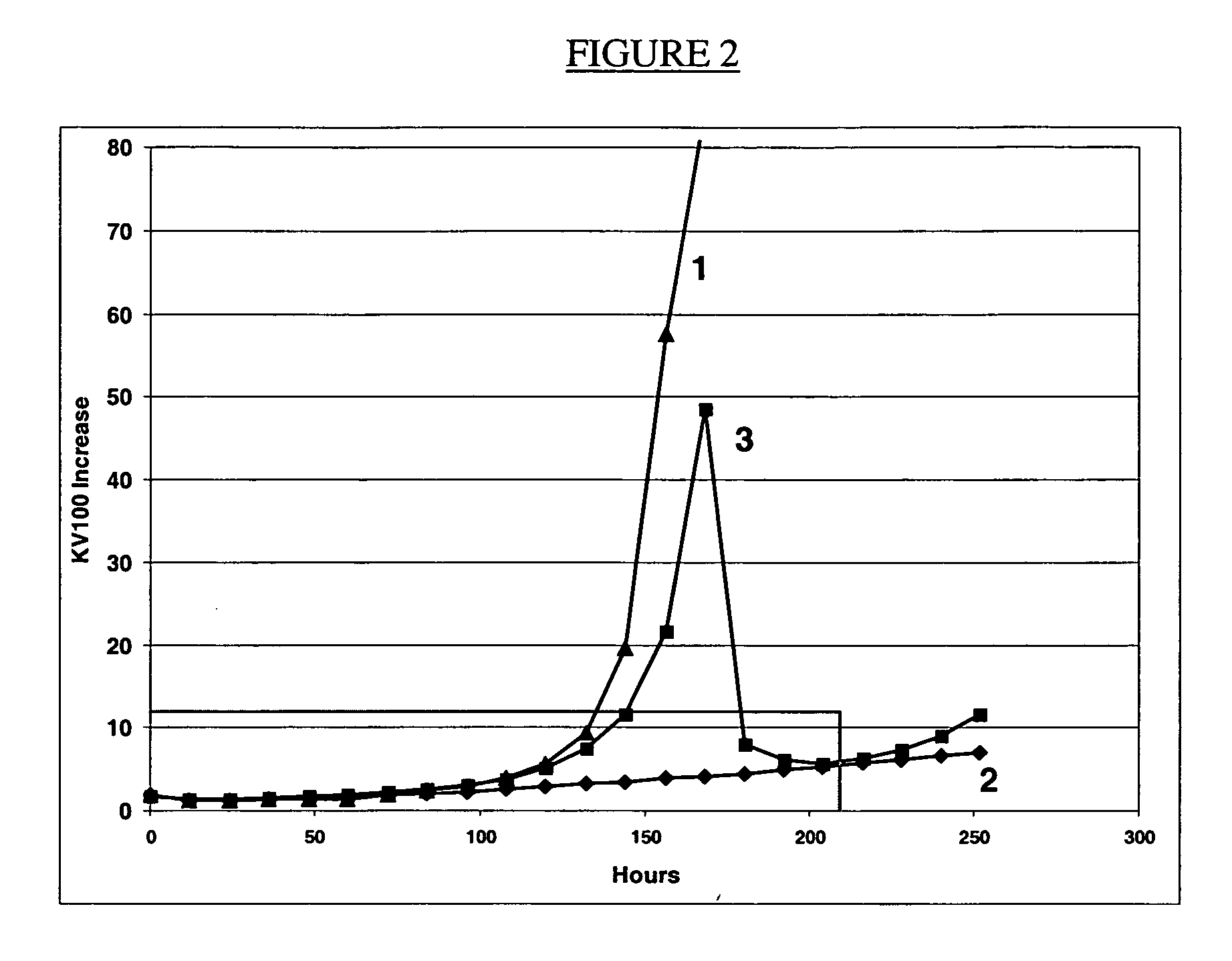

[0014]FIG. 1 illustrates that lubricating oils that meet standard industry engine requirements requirements for soot induced viscosity control do not necessarily perform satisfactorily under actual engine operating conditions in the field. In the graph Mack T-8E test results (line 1) and the Mack T-10 test results (line 2) for an oil meeting the API CI-4 classification grade is compared with the results obtained for an engine actually used in the field (line 3). The Mack T-8E evaluates the soot handling capability of engine lubricants with regard to viscosity; this is done to simulate heavy-duty, stop-and-go operation with high soot loading. The test runs for 300 hours with oil samples being taken every 25 hours. The pass / fail criteria of the test includes a maximum viscosity at 3.8% soot of 11.5 cSt (11.5, 12.5, 13.0 cSt for 1, 2, 3 tests). The Mack T-10 test evaluates the oil's ability to minimize cylinder liner, piston ring, and bearing wear in engines with exhaust gas re-circulat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap