Multiple active coil speaker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

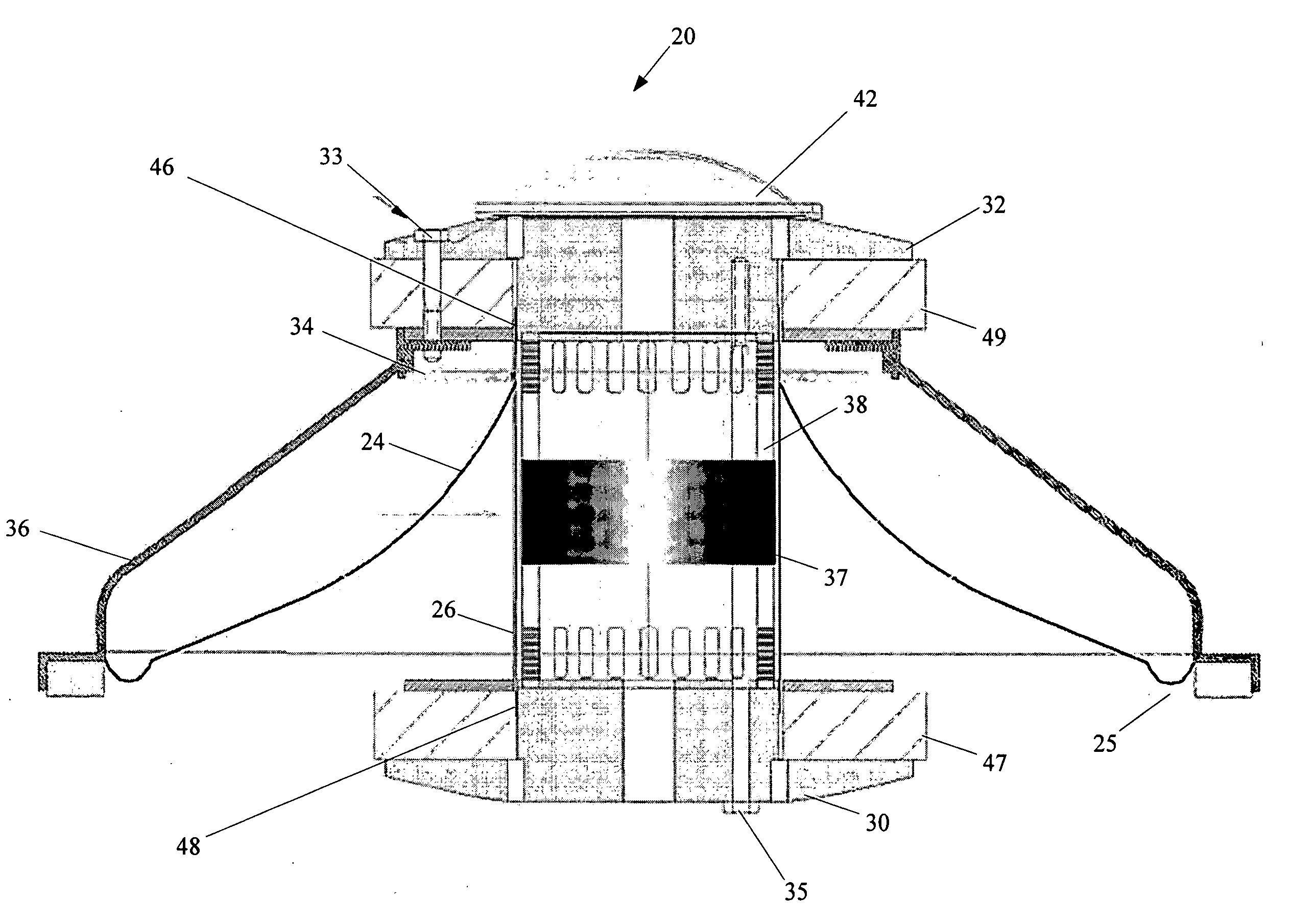

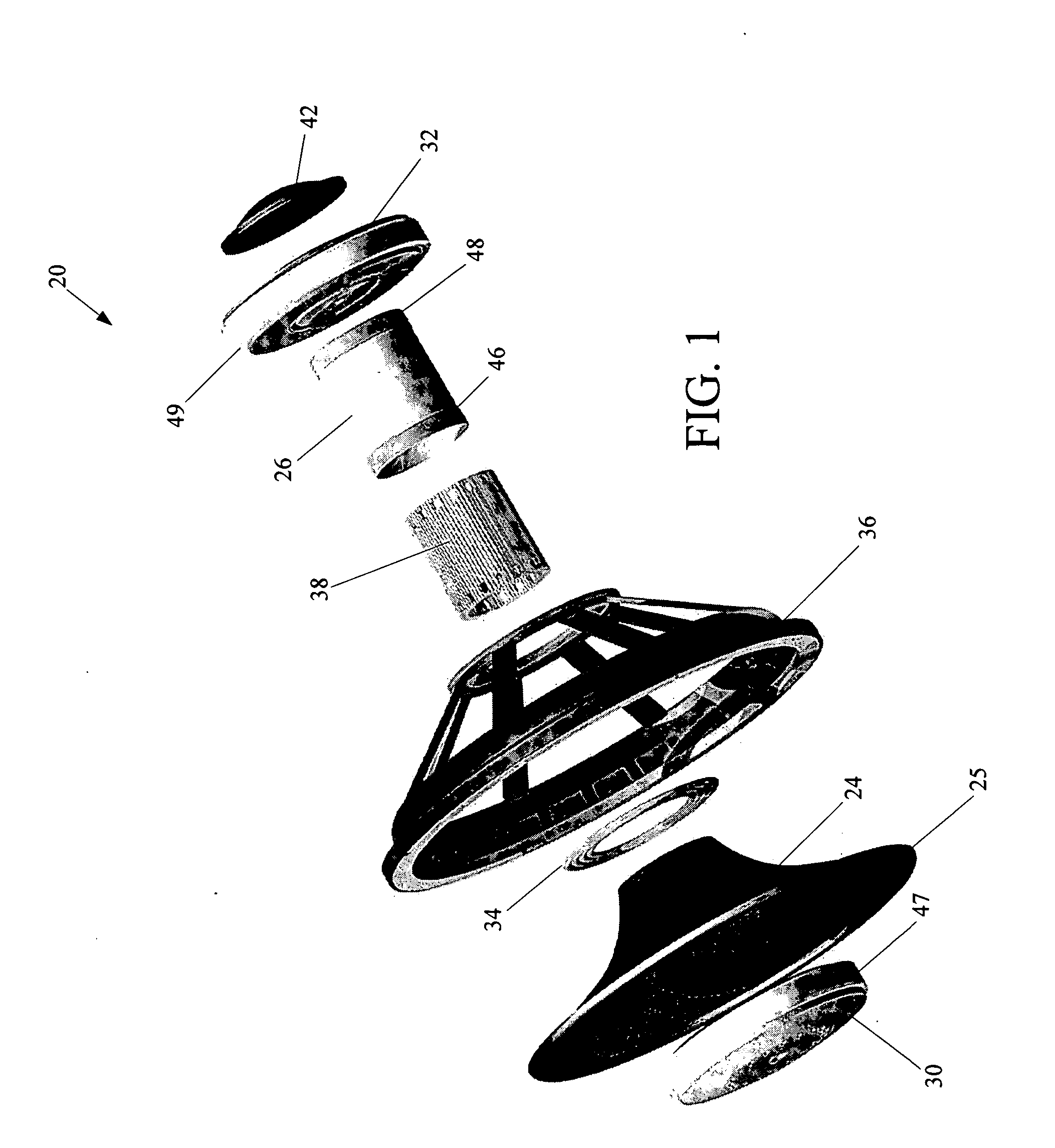

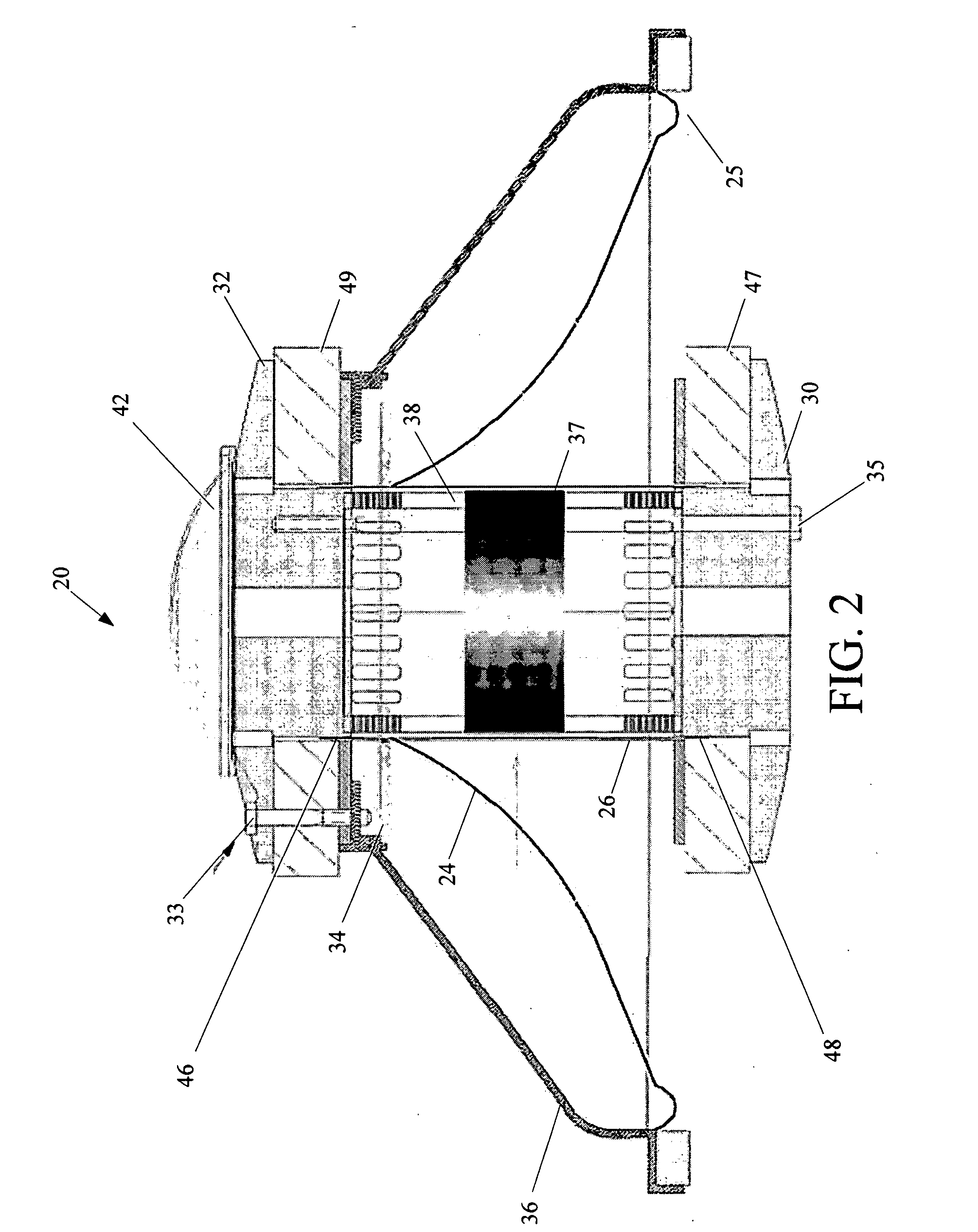

[0028] By way of overview, a voice tube assembly for a loudspeaker comprising a basket, a cone, and a spider includes a first magnet. The first magnet is configured for attachment onto the basket and has a principle axis. A second magnet, the second magnet configured the magnet being coaxial with the first magnet and spaced apart from it. A voice tube of non-ferrous material includes a cylindrical sleeve having a first extremity, a second extremity, and a cylinder axis. The cylinder axis is arranged to coincide with the principle axis. A first voice coil of conductive wire is wrapped around the first extremity in operational proximity to the first magnet. A second voice coil of conductive wire is wrapped around the second extremity in operational proximity to the second magnet.

[0029] A conventional loudspeaker is generally constructed of a metal frame or basket to which is attached, by means of an elastic surround, a cone, made of paper, plastic, or, rarely, metal. Near an apex of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap