Carrier for electrostatic latent image developer, production method thereof, electrostatic latent image developer, and image-forming device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0129] Hereinafter, the present invention will be described specifically with reference to Examples. In the following description, “part” and “%” mean “part by mass” and “mass %” respectively, unless specified otherwise,

(Carrier Core (Core Material))

[0130] Taw materials are blended in amounts of 20 mol % as MnO and 80 mol % as Fe2O3, and a small amount of SiO2 is added thereto for control of the surface shape of the ferrite core. After addition of water, the mixture is pulverized and blended in a wet ball mill for 10 hours, dried, and kept at 950° C. for 4 hours, and then, pulverized in a wet ball mill for 24 hours. The slurry thus obtained is granulated and sintered at 1,300° C. in a nitrogen environment for 6 hours, pulverized, classified, to give manganese ferrite particles (core material). The volume average particle size of the manganese ferrite particles is 40 1m, and the magnetic susceptibility thereof at an applied magnetic field of 3,000 oersteds is 95 emu / g.

[0131] Carri

example 23

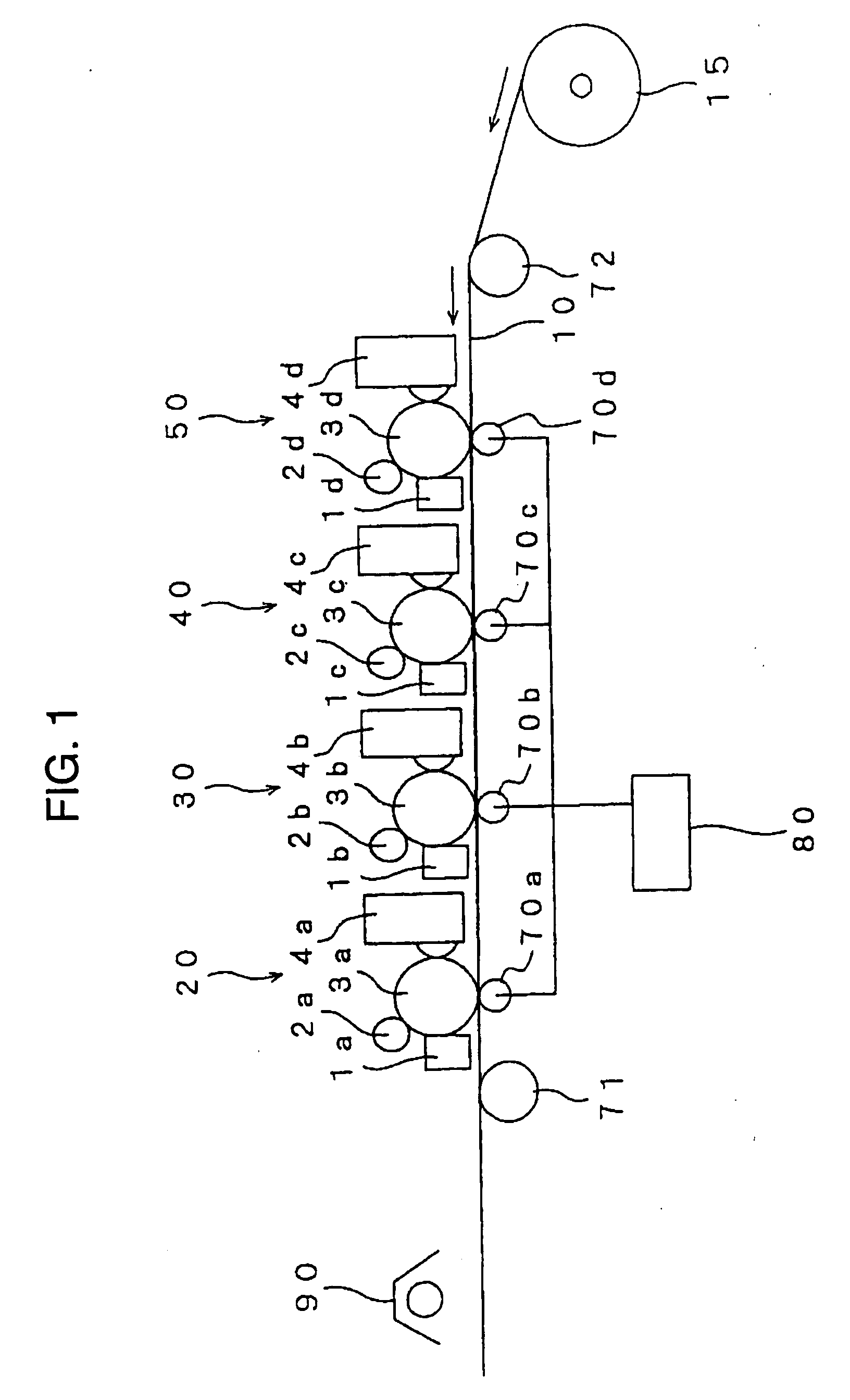

[0179] The modified DOCUPRINT 1100CF is further modified into the train-of-four-tandem machine shown in FIG. 1, and a set of developers containing the carrier 5, YMC toners and an invisible toner is filled in the four developing unit, and a printing test of printing on 1,000,000 sheets is performed.

[0180] As a result, even after printing on 1,000,000 sheets, an image favorable without change in lightness, chroma, toner adhesion, and toner concentration is obtained.

[0181] As described above, it is found that it is possible to form a high-quality image without separation of carbon black form the carrier surface even in a printing machine in a high-speed process with an output of 400 sheets per minute, by employing the developer using the carrier for electrostatic latent image developer according to the present invention.

[0182] In the development of high-speed electrophotographic printers, the present invention can provide a long-lasting electrostatic latent image developer that provid

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap