Method of making phosphor containing glass plate, method of making light emitting device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

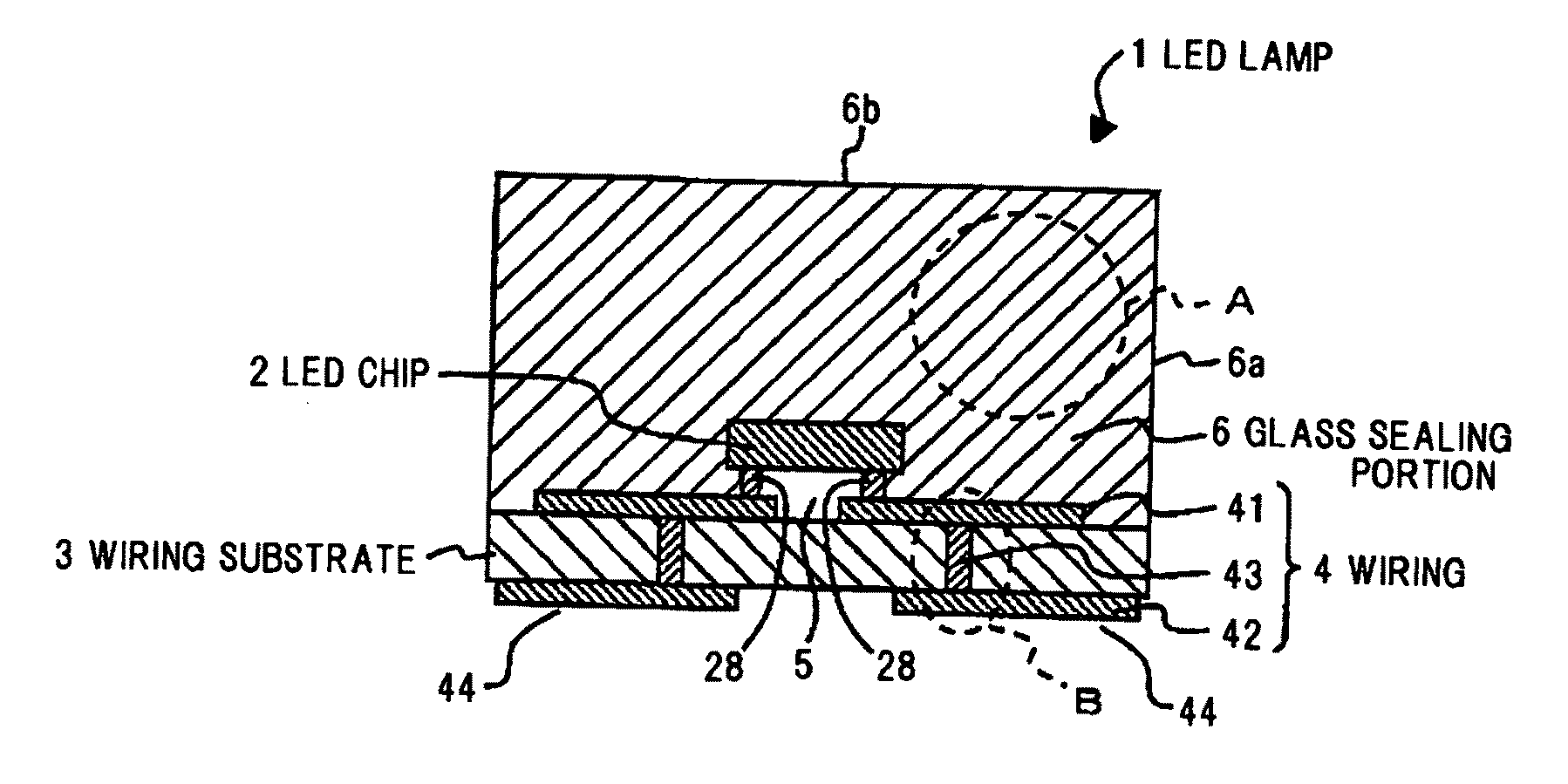

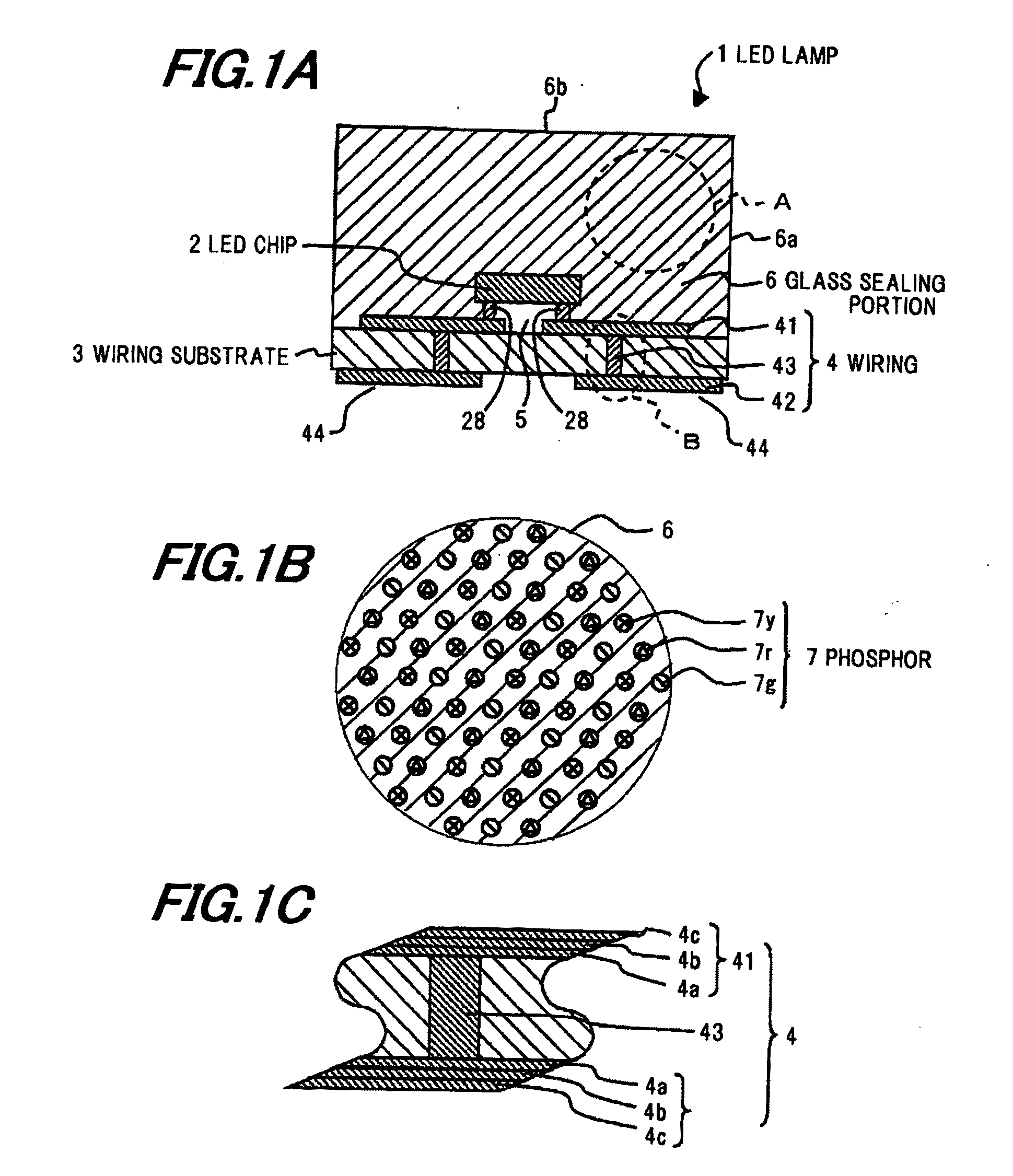

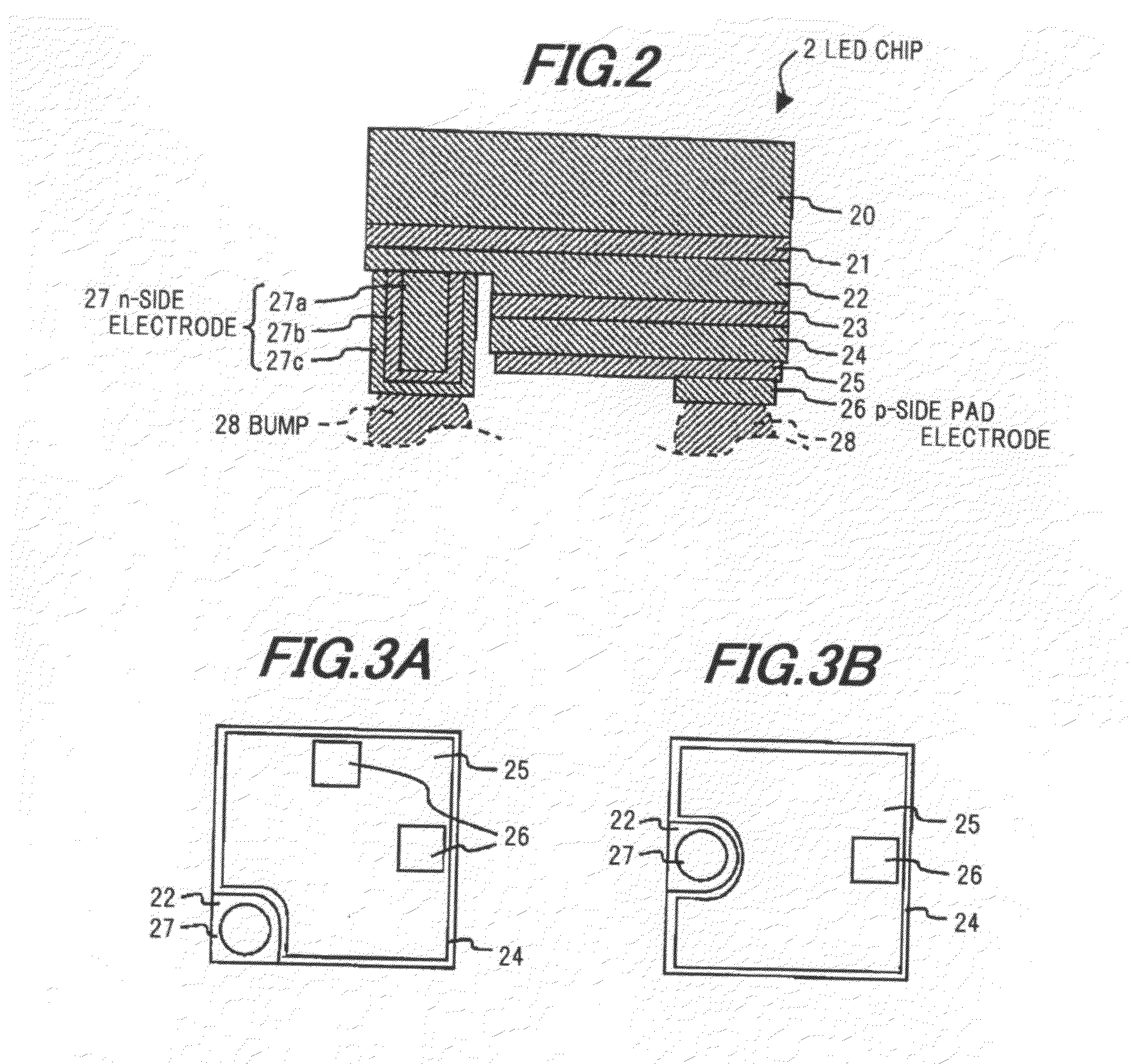

[0049]FIG. 1A to 7 show the preferred embodiment of the invention. FIGS. 1A to 1C are cross sectional views showing an LED lamp in the embodiment. FIG. 2 is a cross sectional view showing an LED chip used in the embodiment.

[0050]As shown in FIG. 1A, the LED lamp (=light emitting device) 1 is composed of a flip-chip type LED chip (=light emitting element) 2, a wiring substrate 3 for mounting the LED chip 2 thereon, a wiring 4 formed on or in the wiring substrate 3, and a glass sealing portion 6 sealing the LED chip 2, adhered to the wiring substrate 3 and containing a phosphor 7 therein.

[0051]As shown in FIG. 2, the LED chip 2 is composed of, grown sequentially on the surface of a crystal growth substrate 20, a buffer layer 21, an n-type layer 22, a light emitting layer 23 and a p-type layer 24 which are of gallium nitride-based semiconductor (Al1-X-YInXGaYN, 0≦X≦1, 0≦Y≦1, 0≦X+Y≦1), and formed by MOVPE (metalorganic vapor phase epitaxy). The LED chip 2 is epitaxially grown at 700° C. or

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap