Vaporizing Pipe Comprising Wire Coils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

[0029]The present invention provides a vaporizing pipe with improved manufacturability and performance and lower cost.

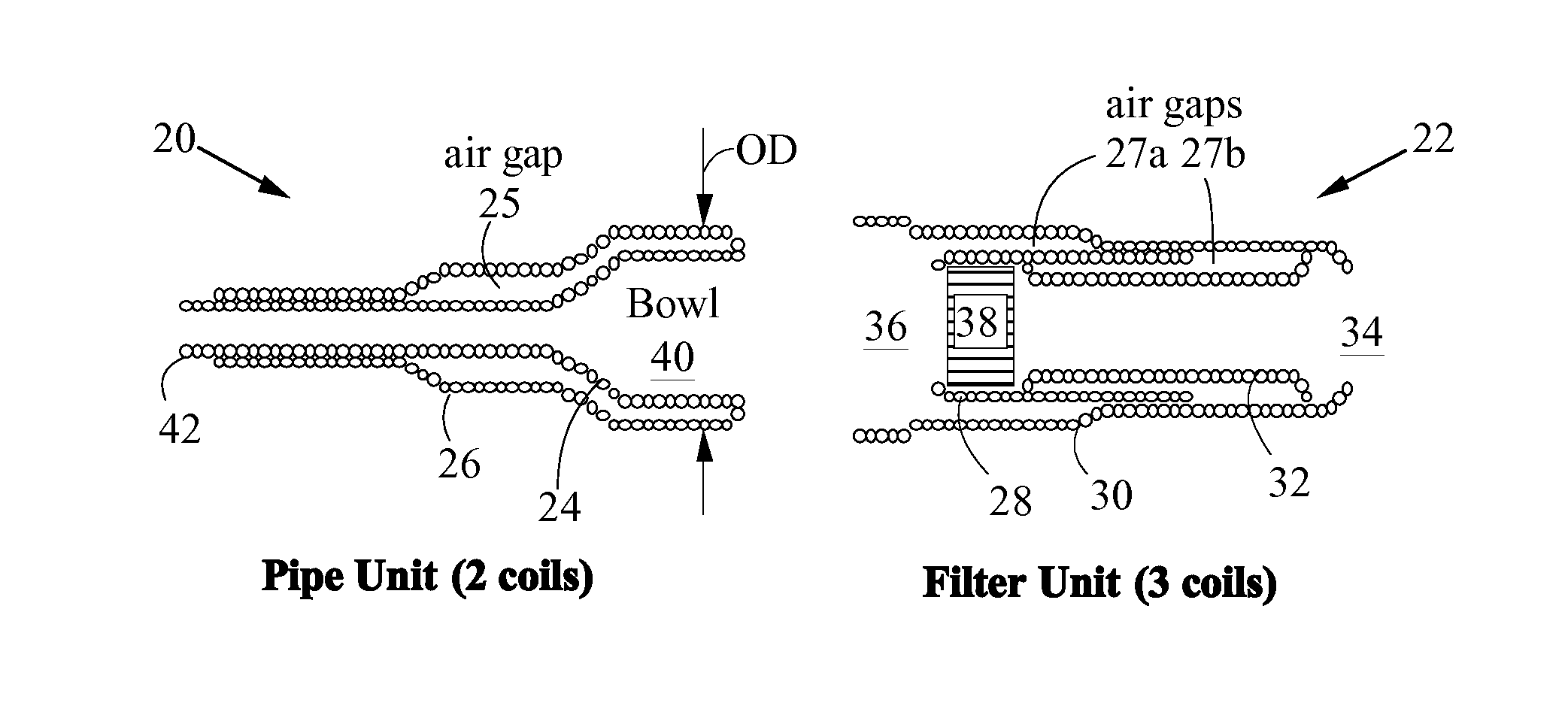

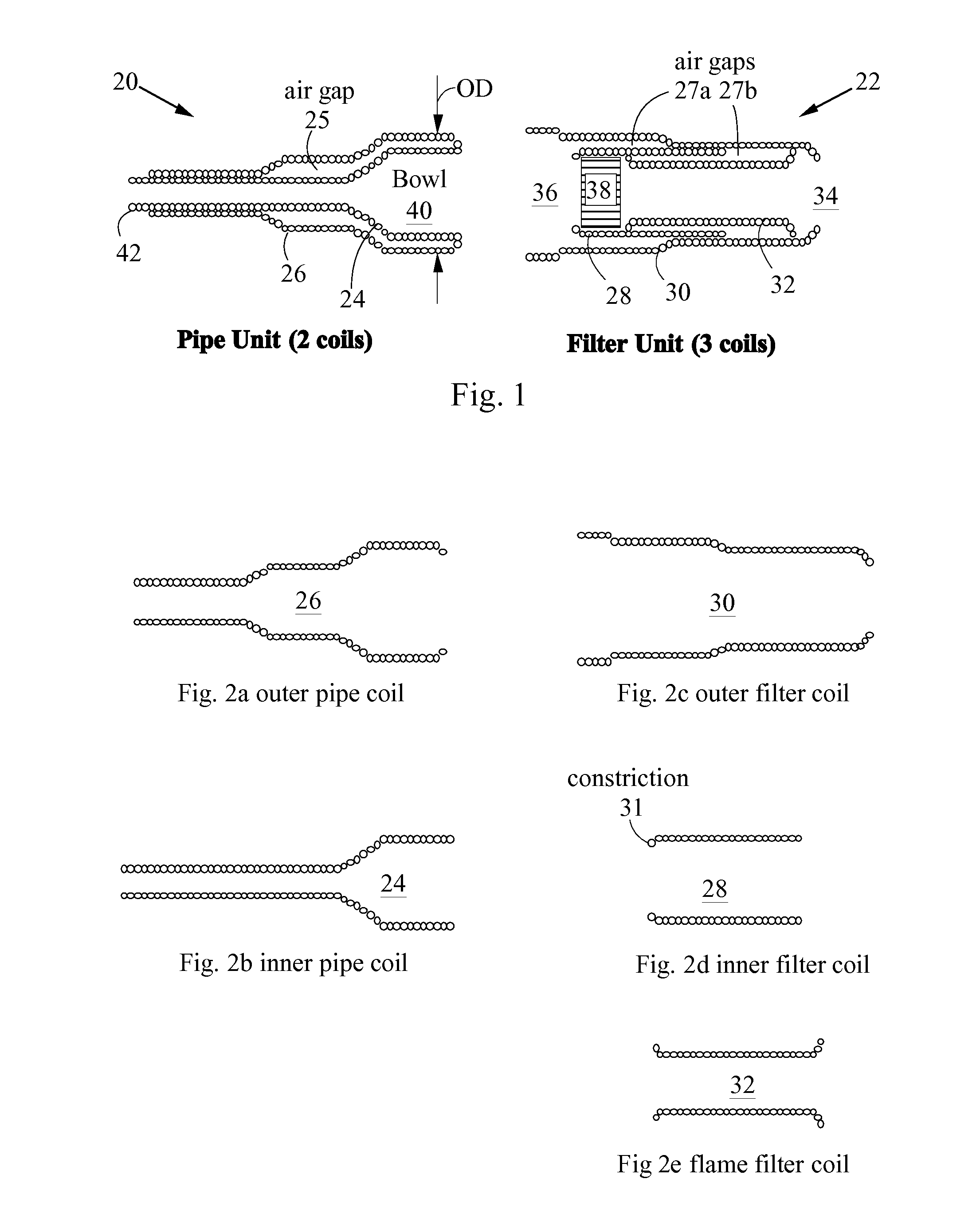

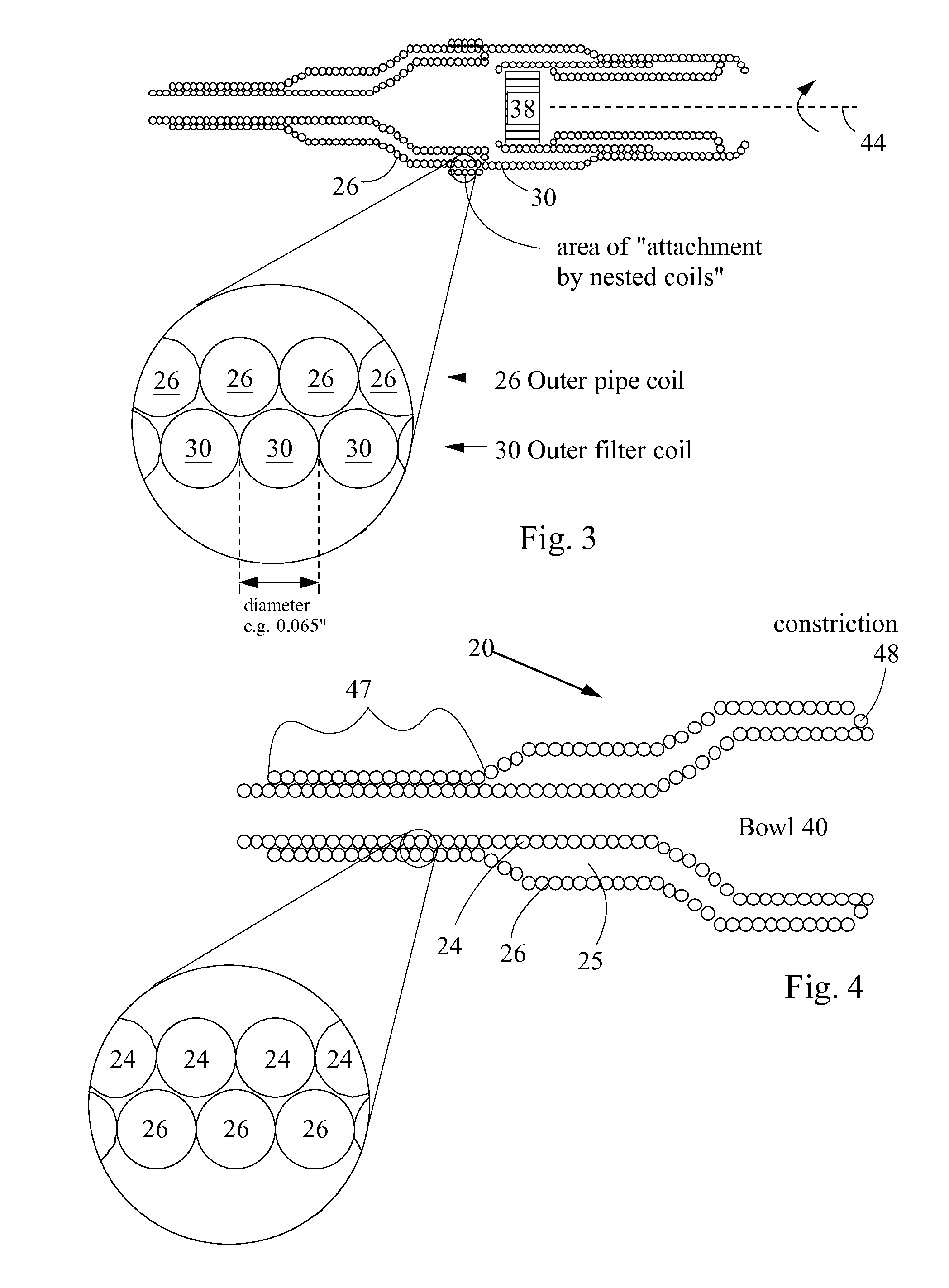

[0030]The present vaporizing pipe comprises a pipe unit and a filter unit. The pipe unit and filter unit each comprise at least one wound wire coil. The wire coils are wound so that they are approximately airtight (i.e. there is at most a small gap between some adjacent coils). Consequently, the wire coils are functionally equivalent to solid-walled tubes. The wire coils are attachable by nested coils. Attachment by nested coils is a natural consequence of making the coils with the same diameter wire because coils made with identical wire have the same “thread pitch”. Also, additional outer wire coils can be provided on both the pipe unit and filter unit. The inner and outer coils can be designed to create air gaps, thereby providing excellent thermal insulation. The present vaporizing pipe can be made of stainless steel at low cost and can be cleaned with liquid cleane

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap