Pressure-sensitive adhesive composition and pressure-sensitive adhesive sheet

a technology of pressure-sensitive adhesives and compositions, applied in the direction of film/foil adhesives without carriers, film/foil adhesives, adhesive types, etc., can solve the problems of deteriorating stability impaired appearance of pressure-sensitive adhesive sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

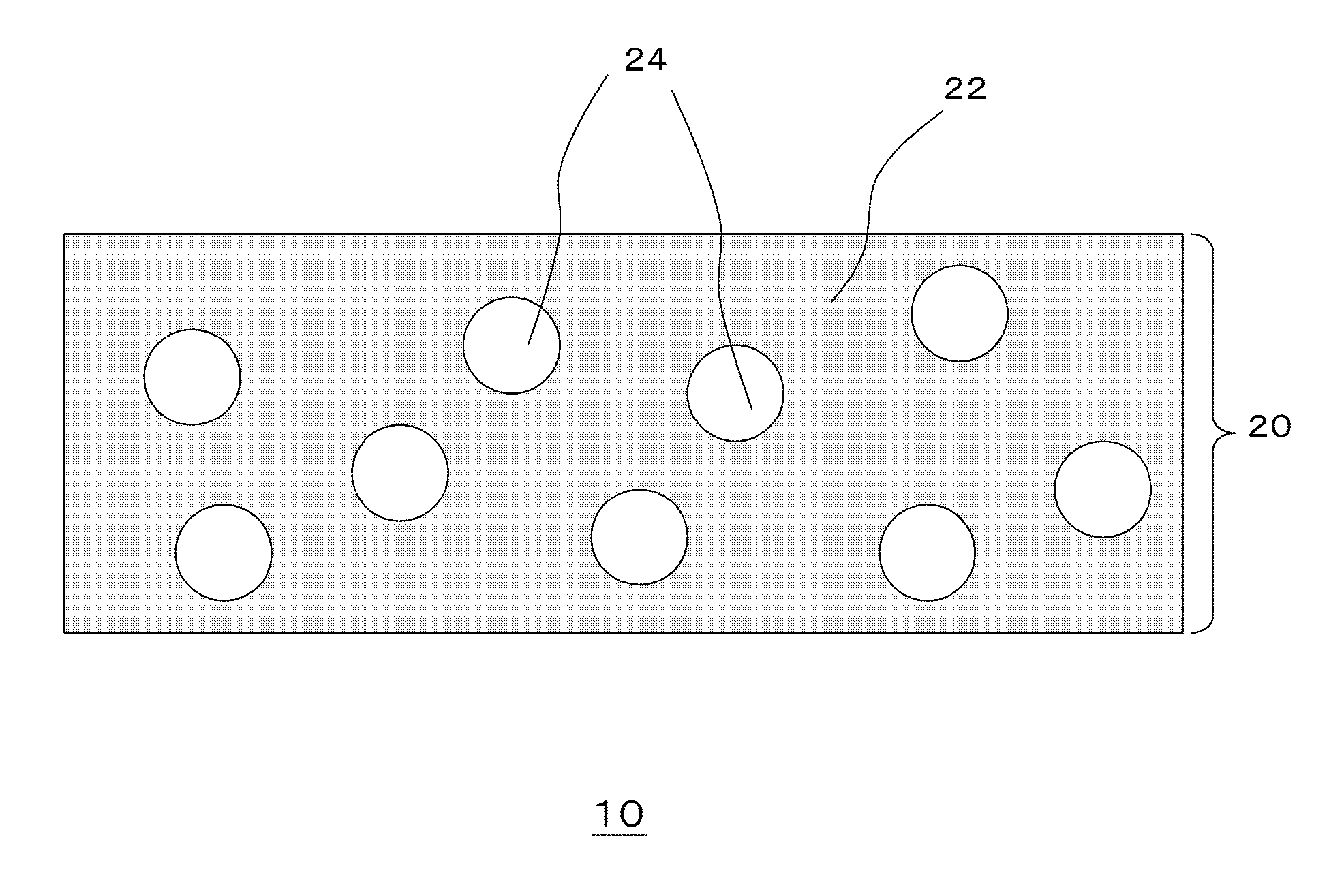

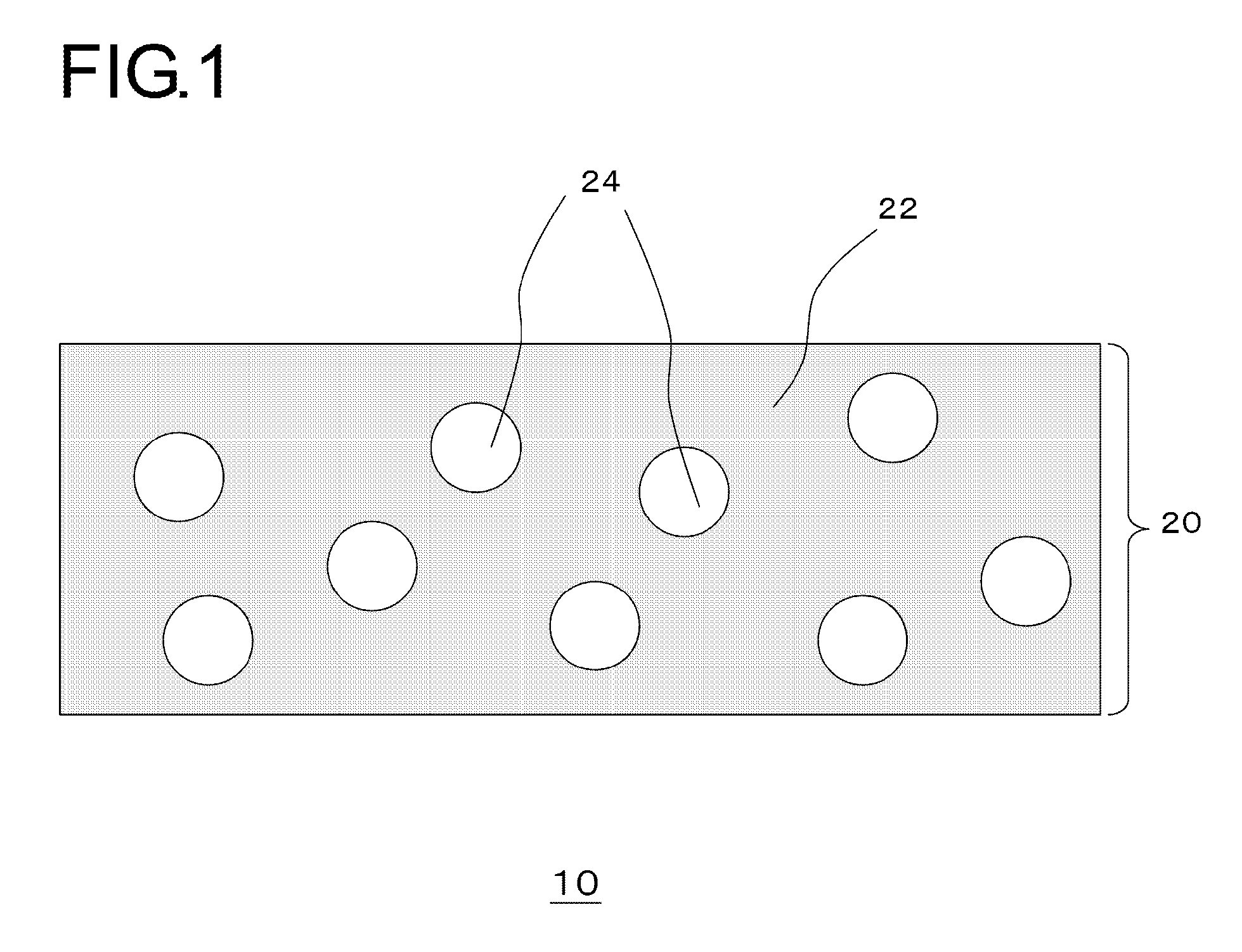

Image

Examples

example 1

[0086]After 0.05 parts by mass of “IRGACURE 651” (product name, made by BASF) and 0.05 parts by mass of “IRGACURE 184” (product name, made by BASF), as photo-polymerization initiators, were blended and mixed into 100 parts by mass of 2-ethylhexyl acrylate (2EHA) as a monomer component, the mixture was irradiated with ultraviolet (UV) rays before the viscosity thereof (BH viscometer, No. 5 rotor, 10 rpm, measurement temperature: 30° C.) became approximately 9.0 Pa·s to produce a composition (syrup) in which part of the monomer component was polymerized. Thereafter, 1.00 part by mass (converted into solid content) of a fluorochemical surfactant (F-477 made by DIC Corporation) as a surfactant and 0.10 parts by mass of NK-Ester A-HD-N (made by SHIN-NAKAMURA CHEMICAL Co., Ltd.) as a cross-linking agent were added to the partially polymerized monomer syrup to produce a precursor of a pressure-sensitive adhesive composition (sometimes referred to as a “precursor A of a pressure-sensitive adhe

example 2

[0089]A precursor of a pressure-sensitive adhesive composition (sometimes referred to as a “precursor B of a pressure-sensitive adhesive composition”) was produced in the same way as in Example 1, except that 91.5 parts by mass of 2-ethylhexyl acrylate (2EHA), 7 parts by mass of N-vinyl-2-pyrrolidone (NVP), and 1.5 parts by mass of N-(2-hydroxyethyl)acrylamide (HEAA) were used as monomer components. After the monomer components and the photo-polymerization initiators were mixed together, the mixture was irradiated with UV rays before the viscosity thereof (BH viscometer, No. 5 rotor, 10 rpm, measurement temperature: 30° C.) became approximately 9.8 Pa·s to produce a composition in which part of the monomer components were polymerized.

[0090]A pressure-sensitive adhesive composition (sometimes referred to as a “pressure-sensitive adhesive composition B”) was obtained in the same way as in Example 1, except that the precursor B of a pressure-sensitive adhesive composition was used. Furthe

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap