Method of manufacturing a near-field light generator including a waveguide and a plasmon generator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

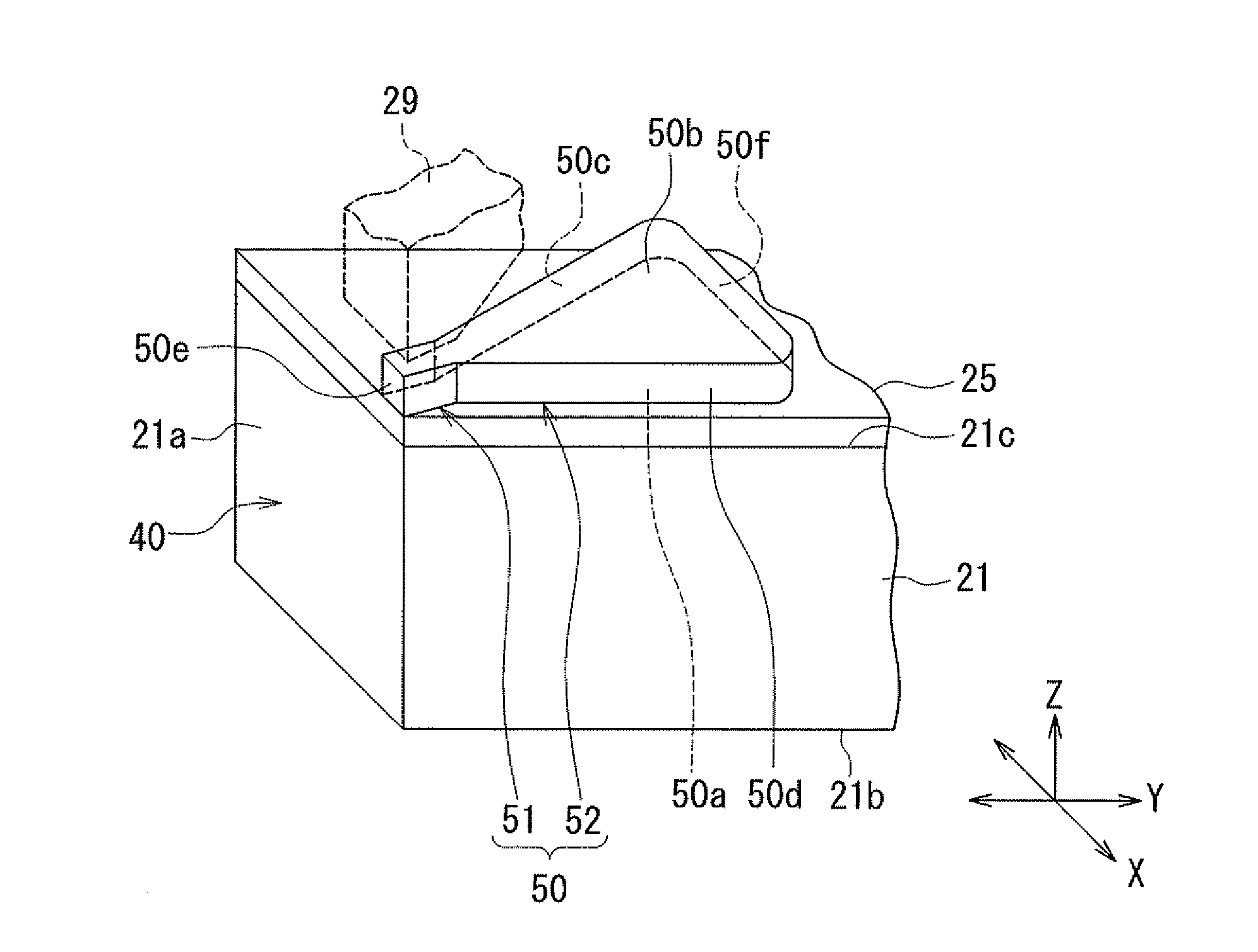

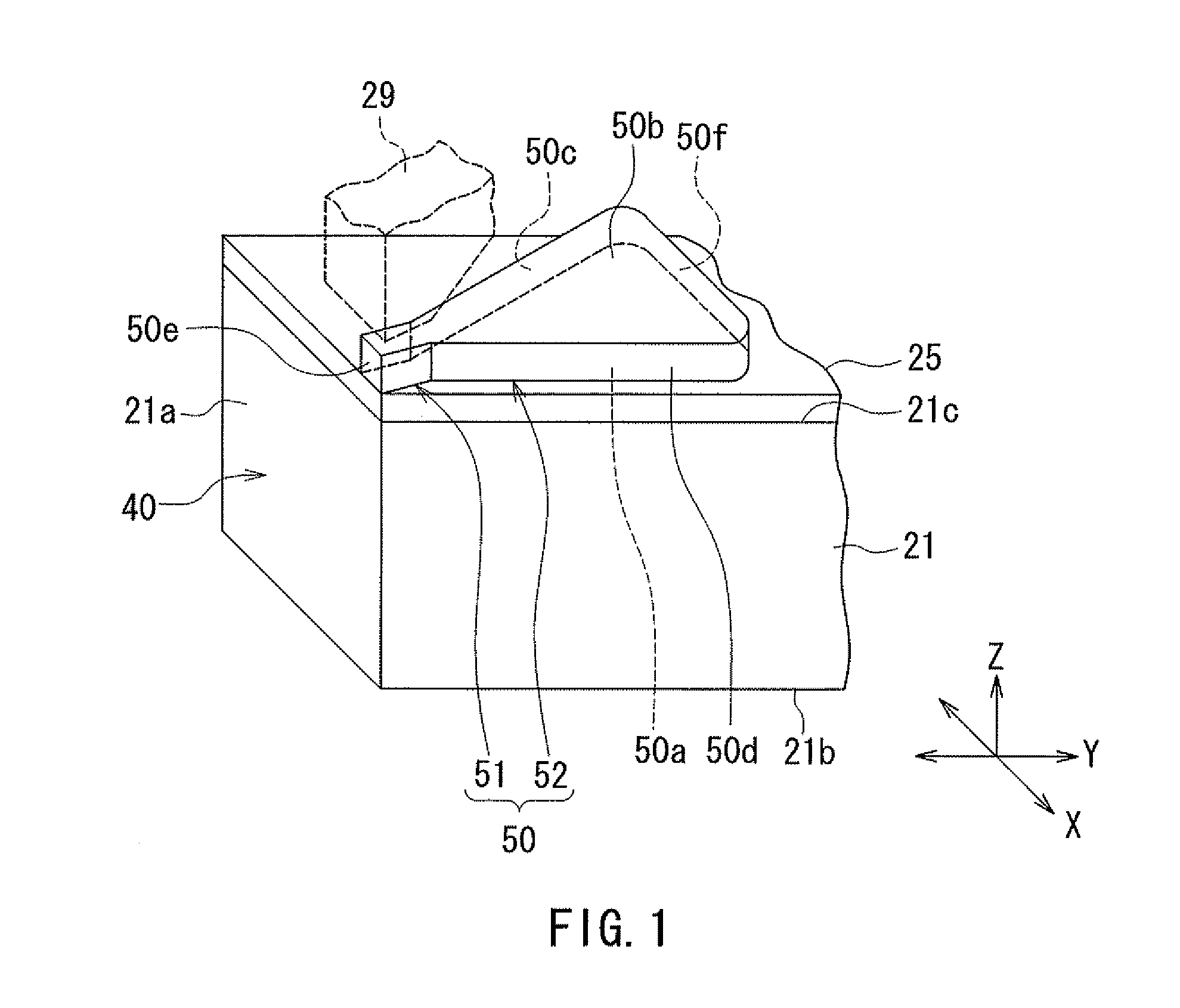

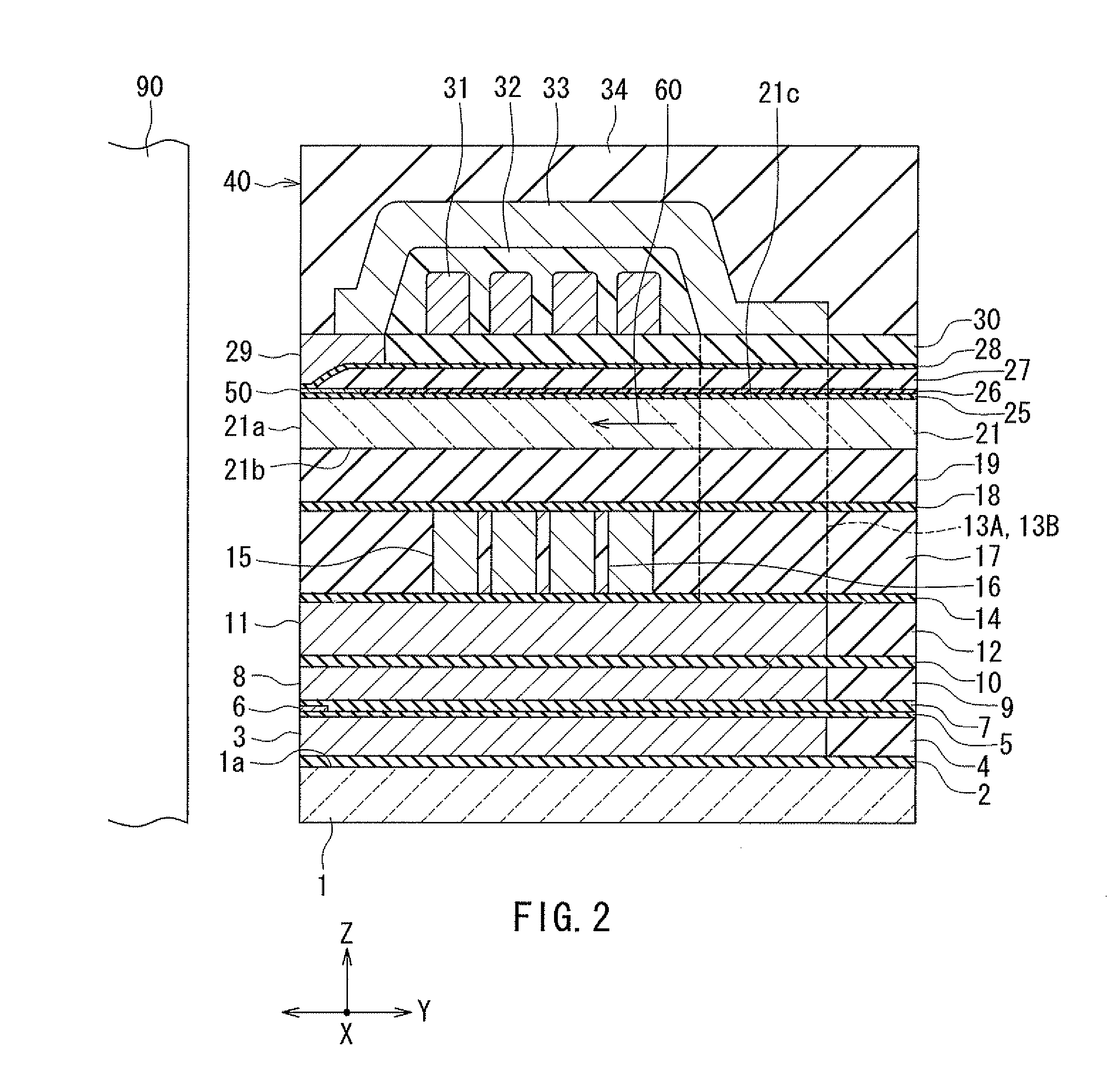

[0042]An embodiment of the present invention will now be described in detail with reference to the drawings. First, reference is made to FIG. 2 and FIG. 3 to describe the configuration of a thermally-assisted magnetic recording head of the embodiment of the invention. FIG. 2 is a cross-sectional view showing the configuration of the thermally-assisted magnetic recording head. FIG. 3 is a front view showing the medium facing surface of the thermally-assisted magnetic recording head.

[0043]The thermally-assisted magnetic recording head of the embodiment is for use in perpendicular magnetic recording, and is in the form of a slider to fly over the surface of a rotating recording medium. When the recording medium rotates, an airflow passing between the recording medium and the slider causes a lift to be exerted on the slider. The slider is configured to fly over the surface of the recording medium by means of the lift.

[0044]As shown in FIG. 2, the thermally-assisted magnetic recording head

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap