Nitride semiconductor device and fabricating method thereof

a technology of nitride semiconductor and fabrication method, which is applied in the direction of semiconductor devices, basic electric elements, electrical appliances, etc., can solve the problems of increasing the importance of handling the leakage current level and the difficulty of producing high-power nitride semiconductor devices, so as to reduce the breakdown voltage and minimize the increase in leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

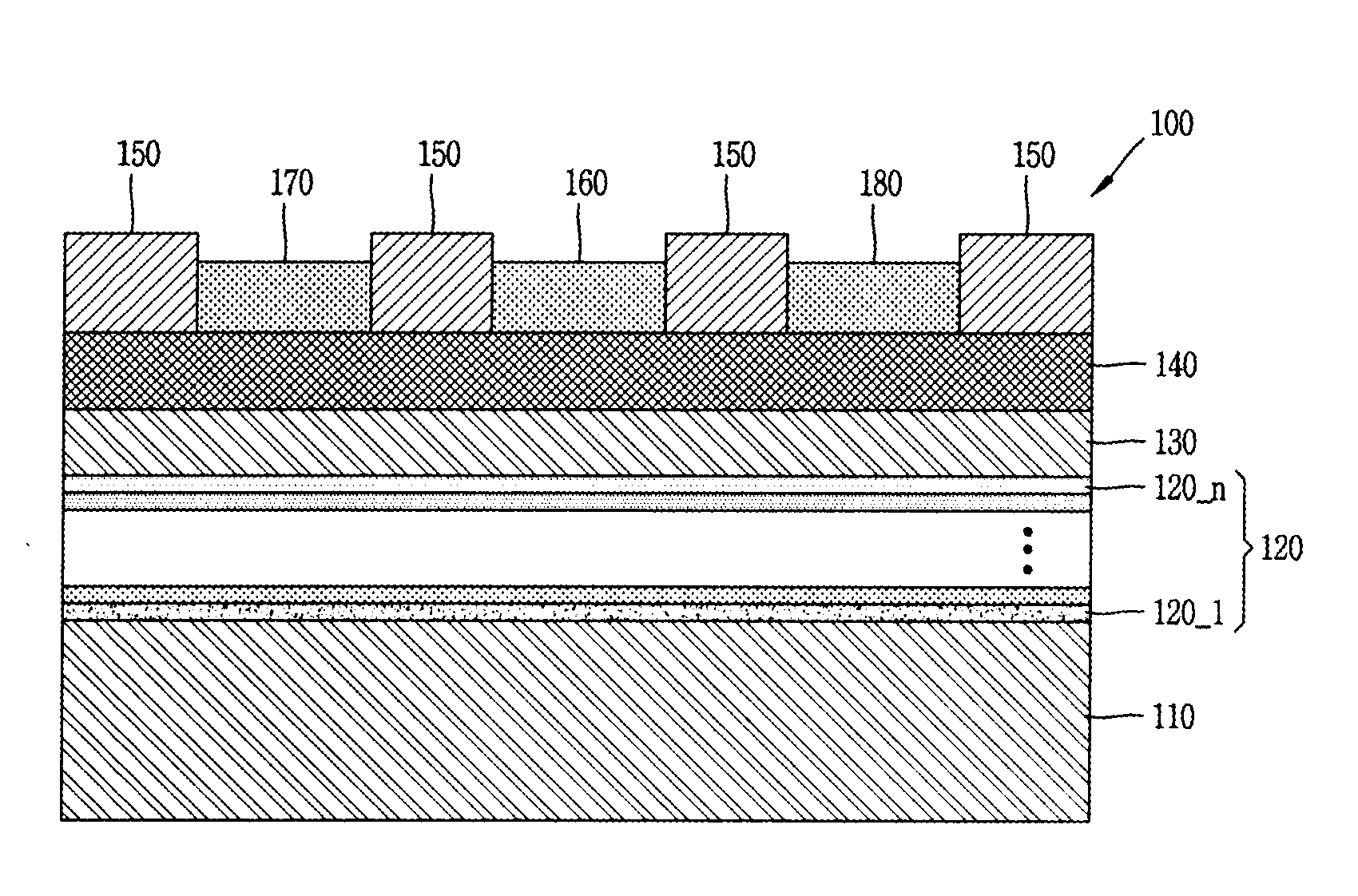

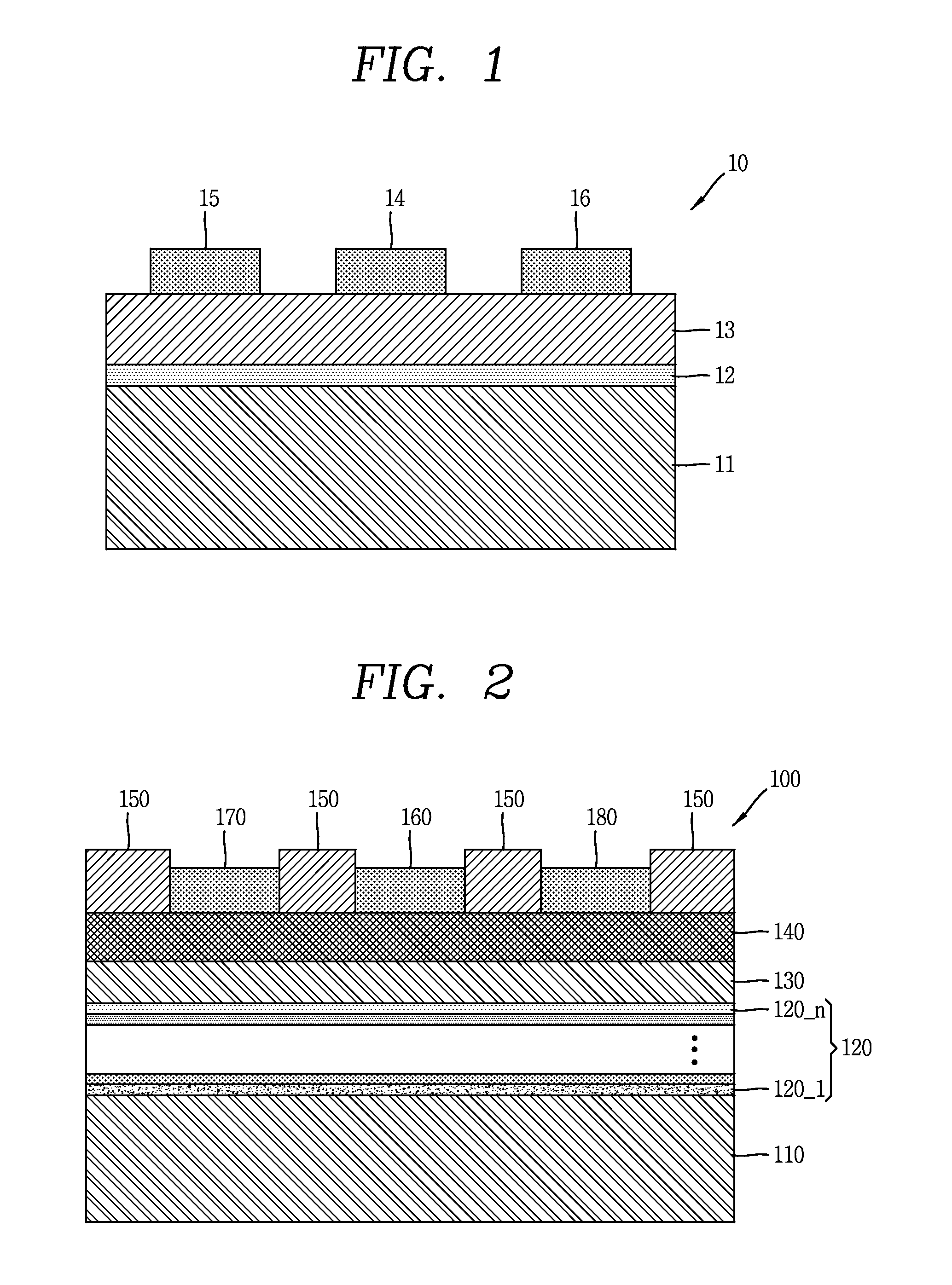

[0062]The technology disclosed herein may be applied to a Heterojunction Field Effect Transistor (HFET) and a fabricating method thereof. The technology disclosed herein is not limited to this, and may also be applicable to all kinds of application fields of nitride semiconductor devices and fabricating methods thereof to which the technological spirit of the technology can be applied.

[0063]Recently, a light-emitting diode (LED) including red wavelength bands in ultraviolet rays and a reddish-blue laser diode have been completely developed according to a growth technique of a nitride semiconductor, and are being widely used for traffic lights, electric signs, mobile phones and the like.

[0064]A power device using the nitride semiconductor has fast switching speed, an excellent withstanding voltage and fast current saturation speed, as compared with an Si-based device, and thus has many advantages for high-output high-voltage rather than the Si-based semiconductor devices.

[0065]That is,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap