Pressure sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

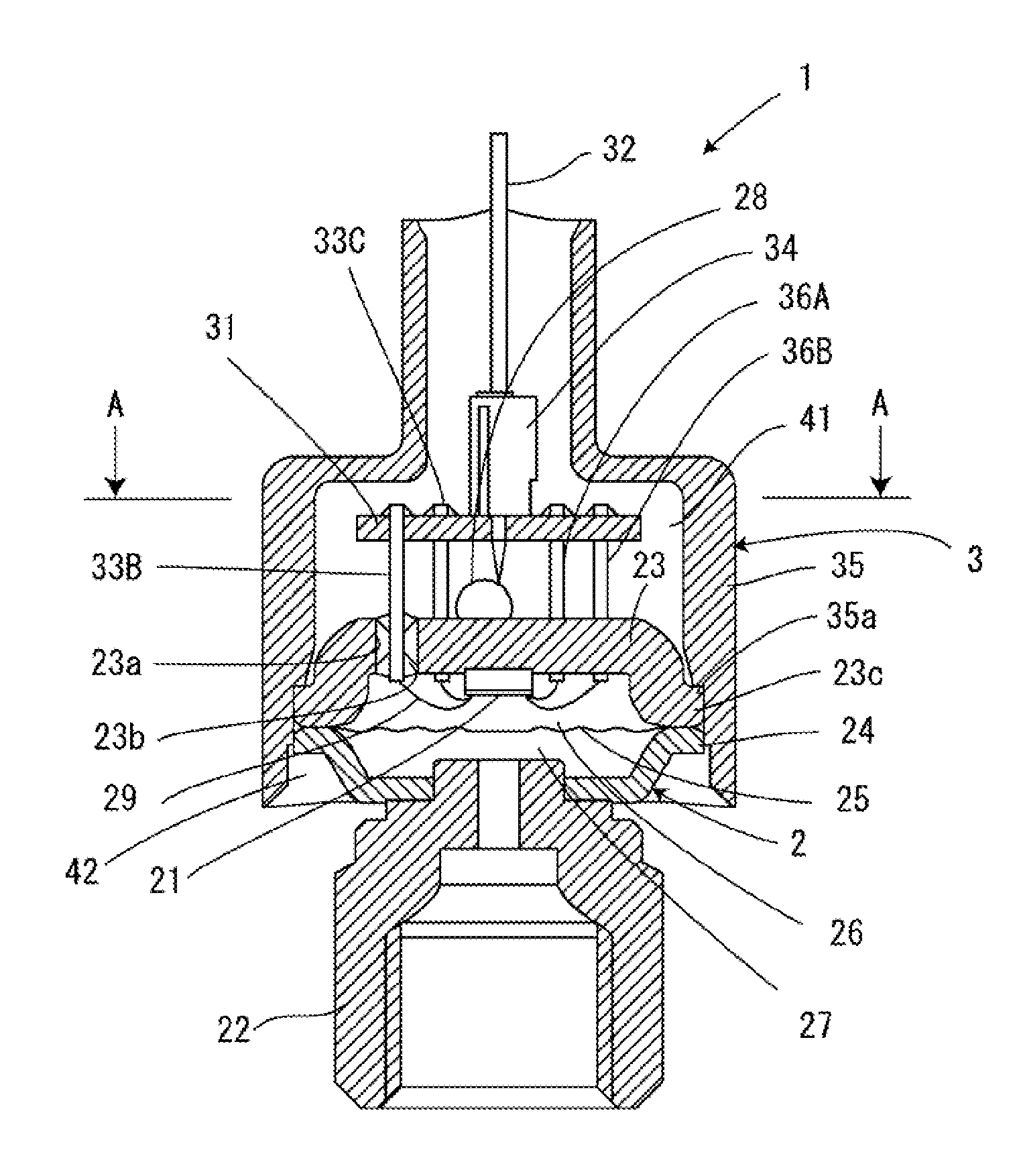

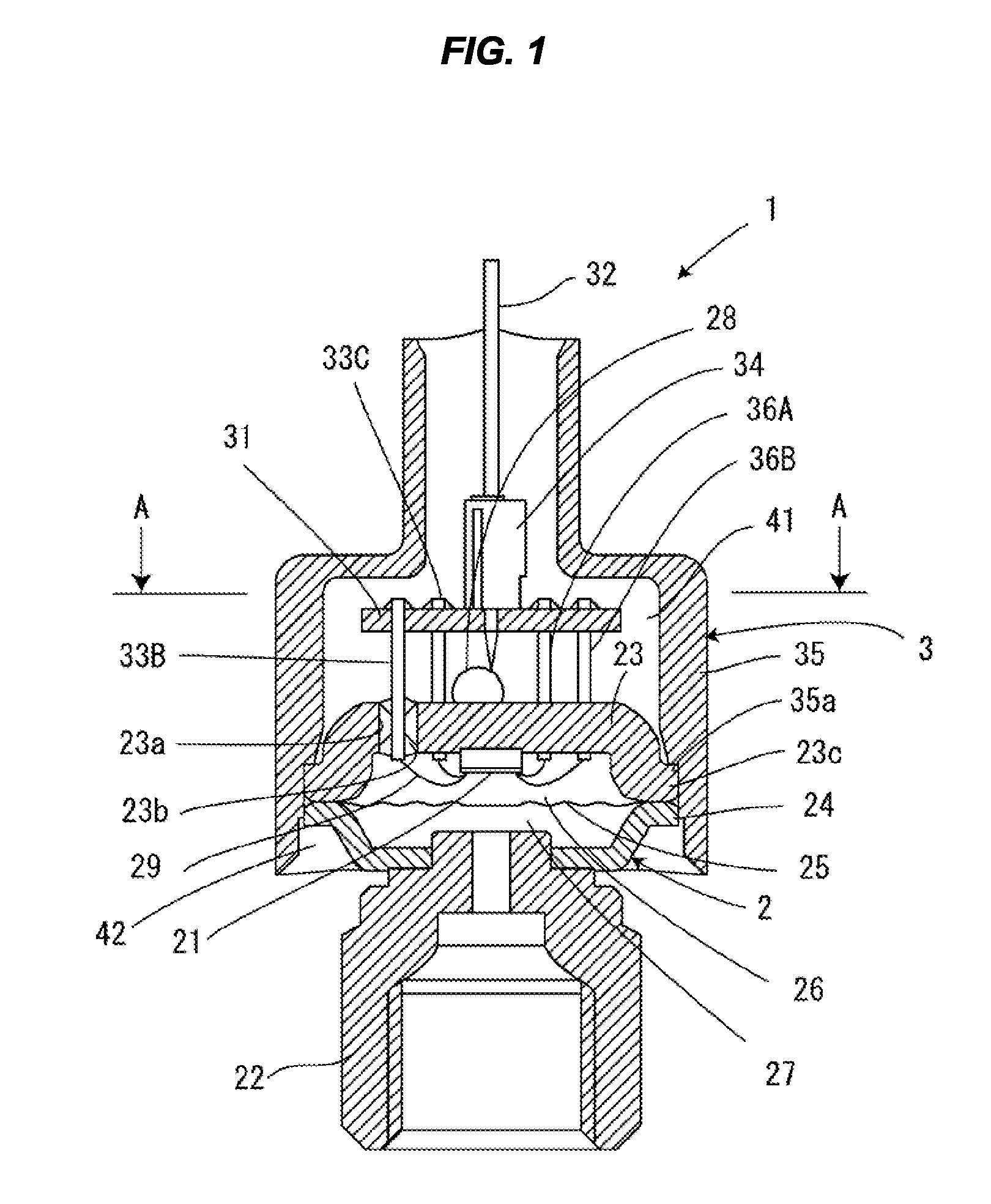

[0014]As illustrated in FIG. 1, a pressure sensor 1 includes a stepped cylinder cover 35. In an opening of the cover 35 having a large diameter, there is mounted a semiconductor pressure detection device 2. The semiconductor pressure detection device 2 includes a base 23 which is provided with a pressure detection element 21 to be described below, a receiving member 24 which supports a fluid inflow section 22 connected to a fluid inflow pipe (not illustrated), and a diaphragm 25 of which the outer peripheral portion is interposed between the base 23 and the receiving member 24.

[0015]An insulative liquid medium such as oil fills a pressure receiving space 26 which is partitioned by the plate-like base 23 and the diaphragm 25. A ball 28 is used to seal a through hole (not illustrated) formed in the base 23 after the pressure receiving space 26 is filled with the liquid medium through the hole, and is fixed to the base 23 by welding.

[0016]The pressure detection element 21 (a pressure sens

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap