Method and Apparatus for Optimizing Sorptive Storage of Gas

a sorptive storage and gas technology, applied in the direction of specific gravity measurement, container discharge methods, instruments, etc., can solve the problems of increasing storage capacity at the expense, not all the gas adsorption by sorptive materials can be delivered from the storage vessel,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

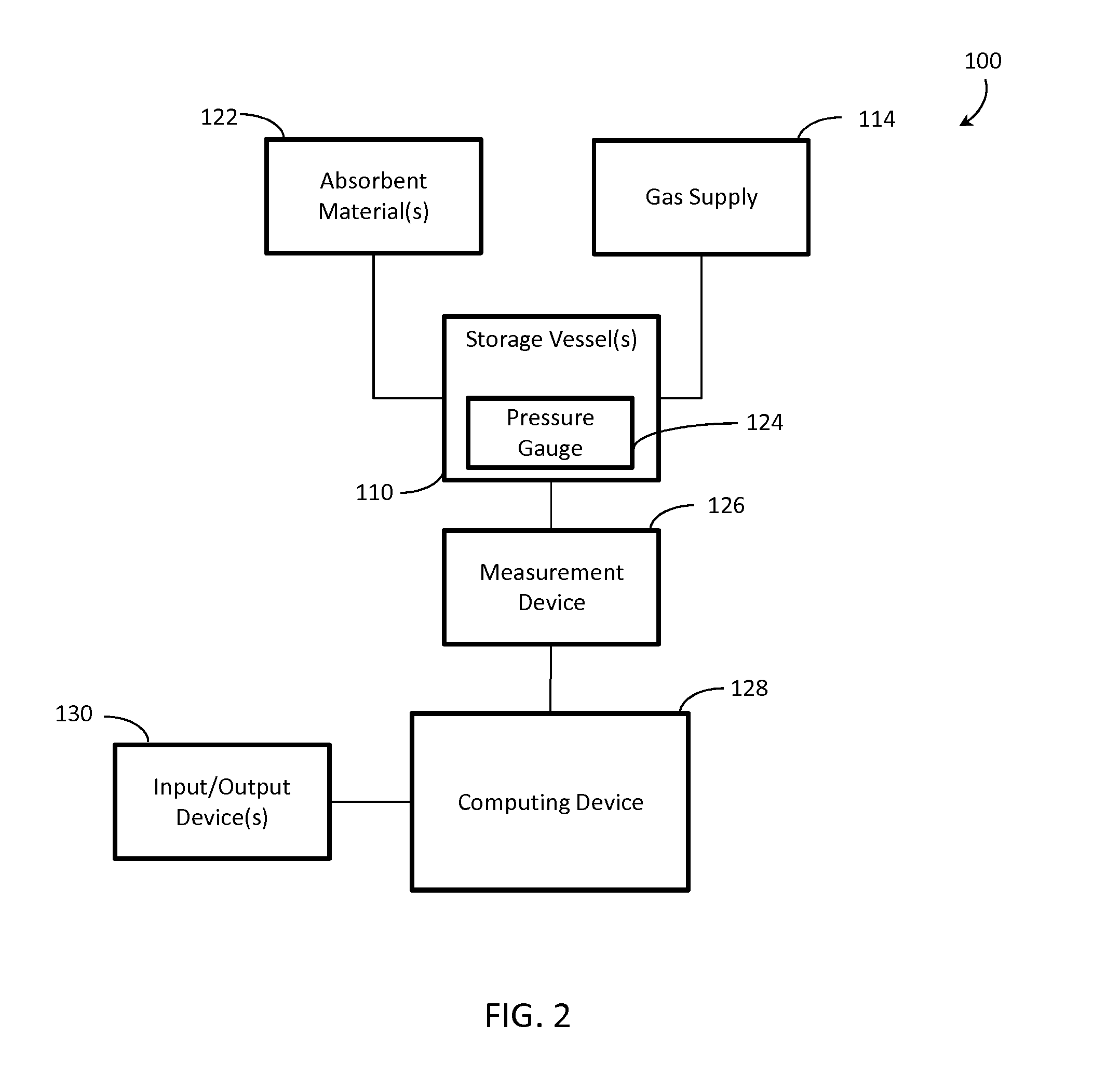

[0012]The present disclosure provides systems and methods for evaluating adsorbent materials within a storage vessel to optimize the storage of gases in the storage vessel. It should be noted that the terms “adsorbent” and “adsorptive”, and the like, as used herein, refer to the use of either a sorbent, sorptive, or an absorbent material.

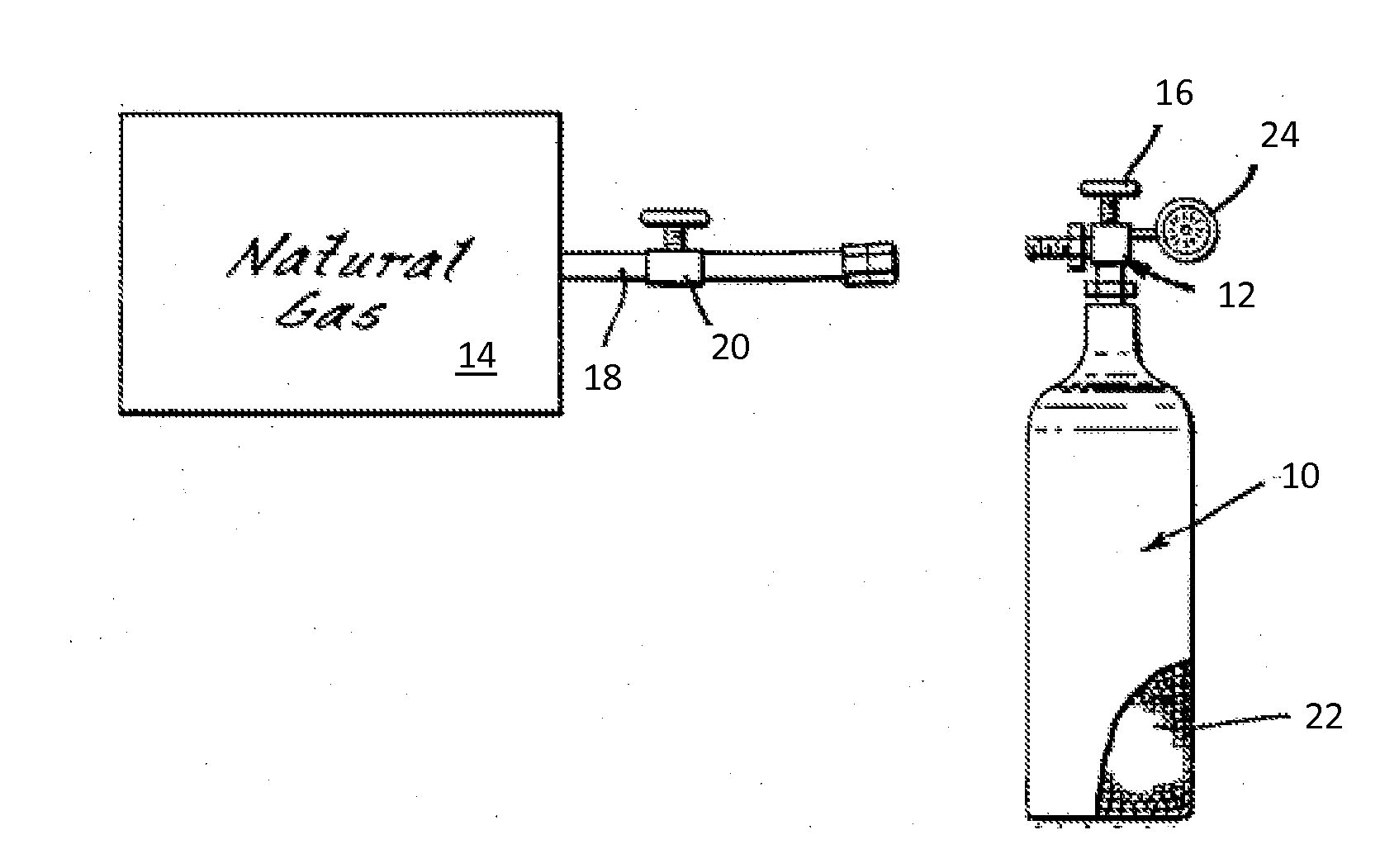

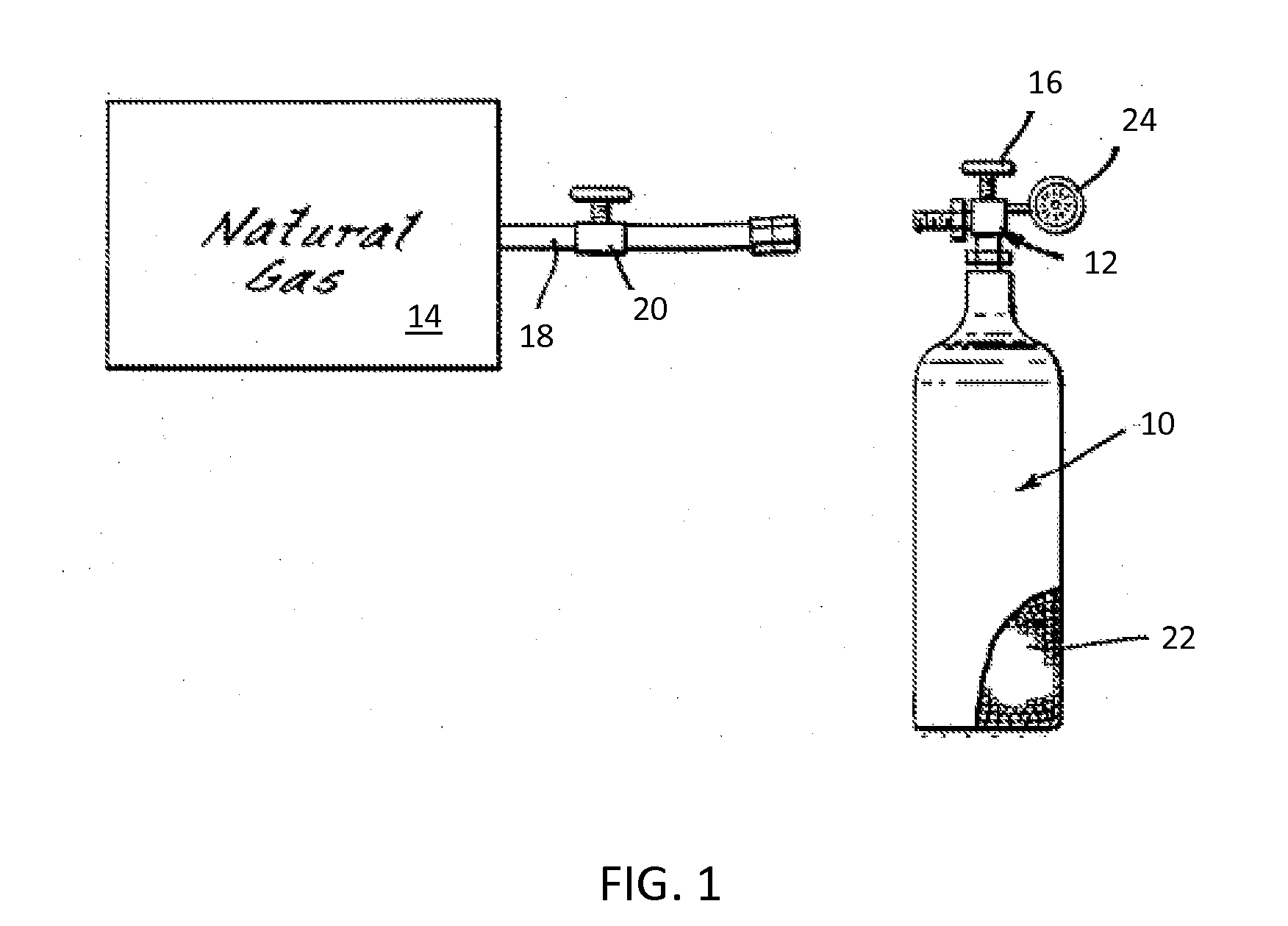

[0013]Referring to FIG. 1, an exemplary storage vessel 10 for storing a gas and an exemplary gas supply source 14 for supplying a gas (e.g., natural gas) to the storage vessel 10 are illustrated. The storage vessel 10 includes an inlet / outlet apparatus 12 configured to allow the storage vessel 10 to be selectively coupled and decoupled in fluid communication with a gas supply source 14. According to some aspects of the present disclosure, the inlet / outlet apparatus 12 can include a shut-off valve 16 configured to selectively open and close the fluid communication between the storage vessel 10 and the gas supply 14. Additionally, the storage vessel

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap