Purification apparatus for compressed air

a technology of purification apparatus and compressed air, which is applied in the direction of vortex flow apparatus, cleaning equipment, separation process, etc., can solve the problems of increased contamination, reduced efficiency of separating oil and foreign substances, and increased contamination, so as to achieve the effect of maximizing air purification efficiency, reducing the efficiency of separating oil and foreign substances, and greatly accelerating the second swirling of compressed air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]Certain embodiments of the present invention are described below with reference to the accompanying drawings.

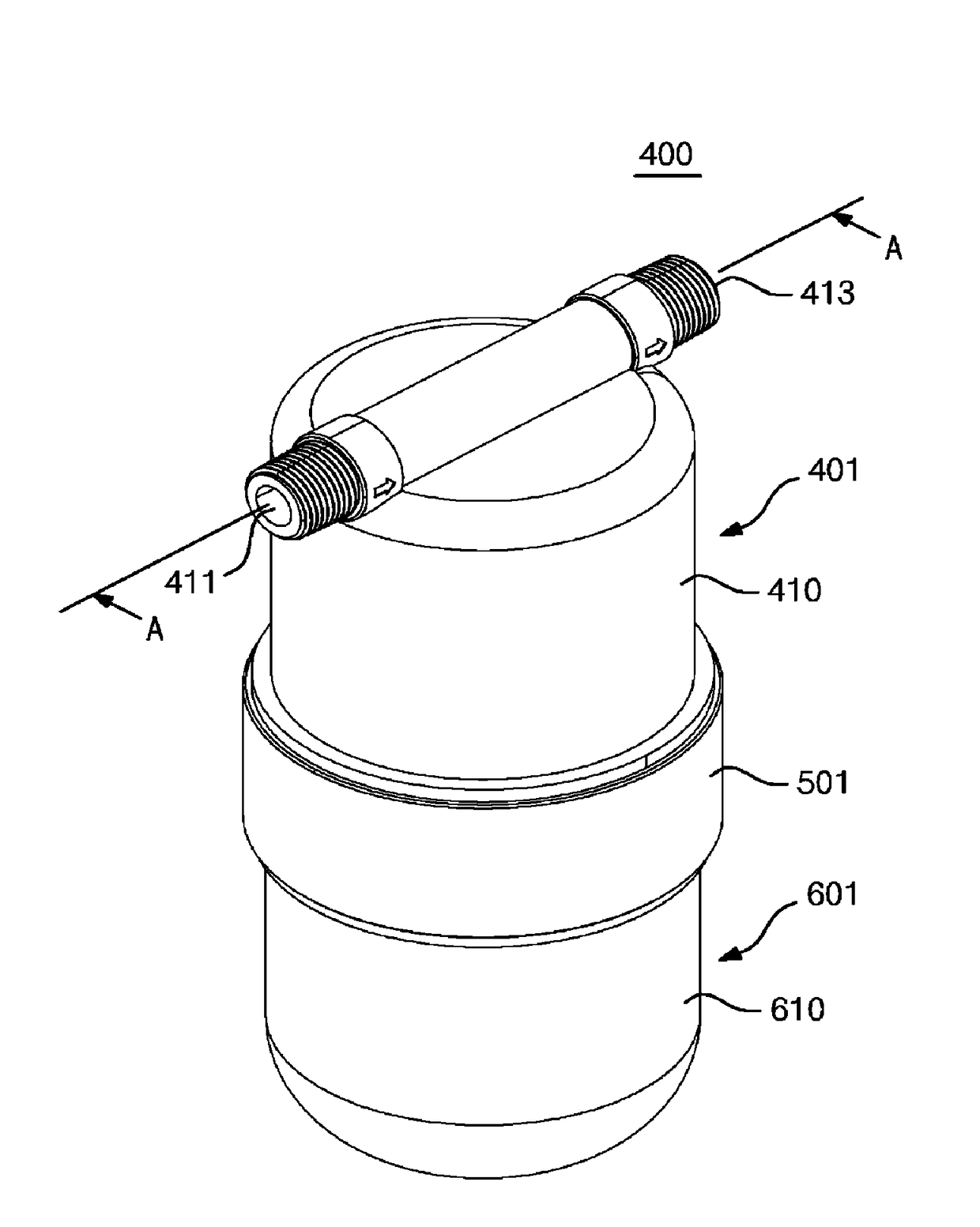

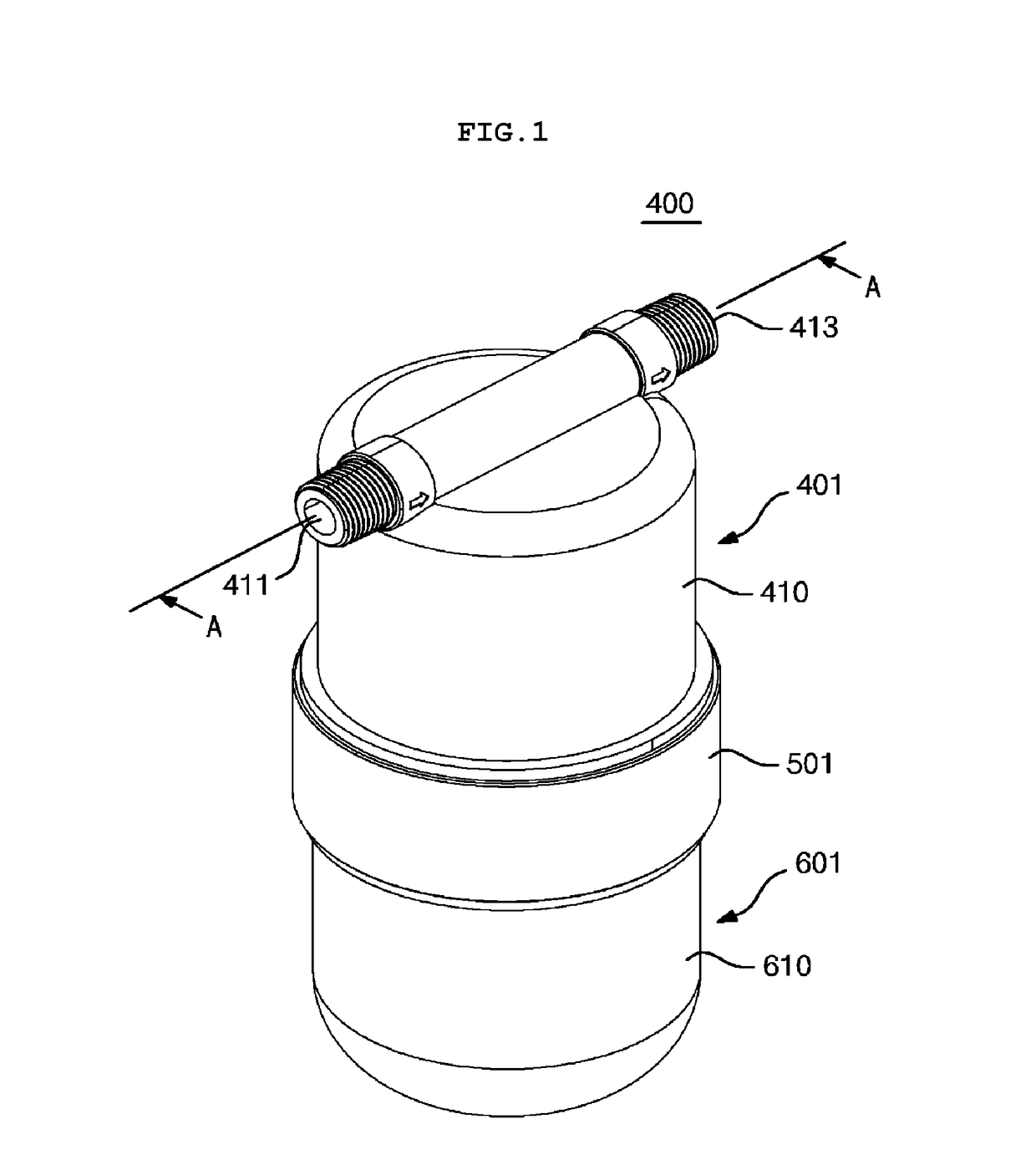

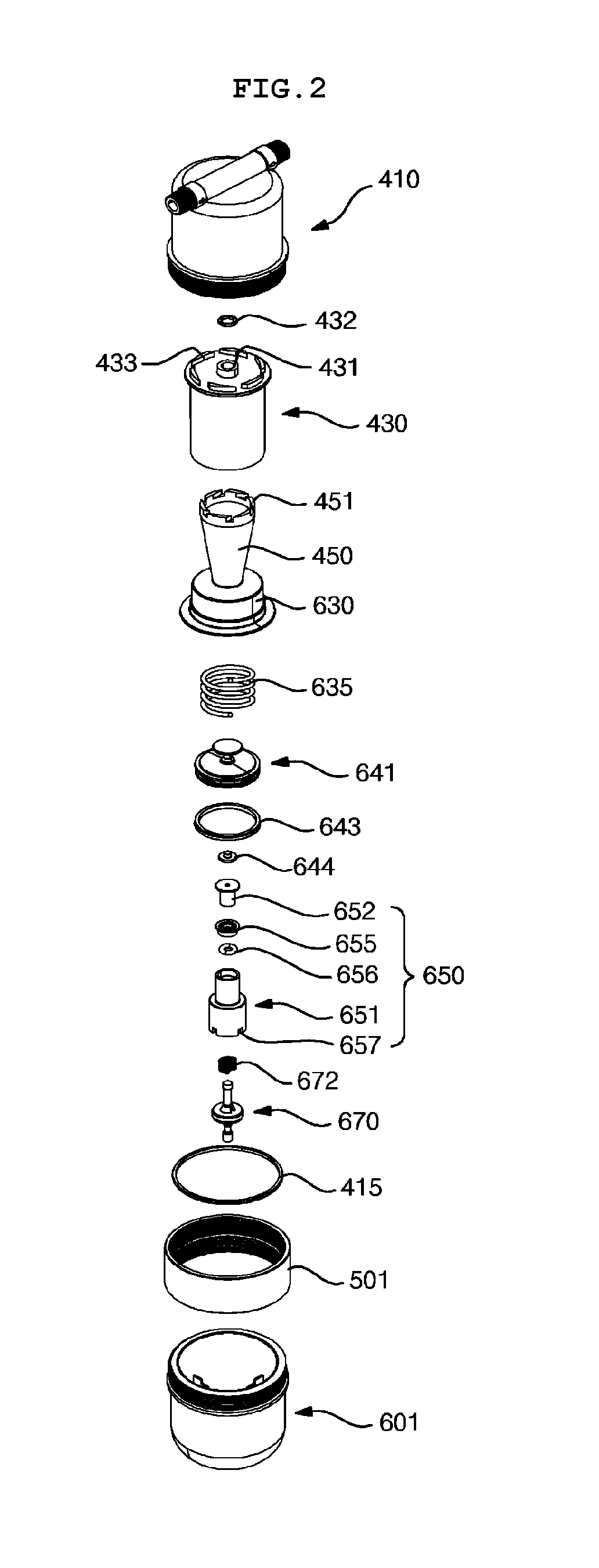

[0037]FIG. 1 is a perspective view of a compressed air purification apparatus according to an embodiment of the present invention, FIG. 2 is an exploded perspective view of FIG. 1, FIG. 3 is a perspective view of the inner drum and the collector drum, FIG. 4 is a cross-sectional view across A-A of FIG. 1, FIG. 5 is a cross-sectional view across B-B of FIG. 4, FIG. 6 is a cross-sectional view across C-C of FIG. 4, FIG. 7a is a cross-sectional view illustrating an operating state of the drain member (compressor OFF, pneumatic device OFF), FIG. 7b is a cross-sectional view illustrating an operating state of the drain member (compressor ON, pneumatic device OFF), and FIG. 7c is a cross-sectional view illustrating an operating state of the drain member (compressor ON, pneumatic device ON).

[0038]As illustrated in FIGS. 1 to 7c, a compressed air purification apparatus 400 accordi

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap