Cleaning equipment and cleaning method of deposition mask

a deposition mask and cleaning equipment technology, applied in the direction of cleaning using liquids, vacuum evaporation coatings, coatings, etc., can solve the problems of difficult collection and recycling of deposition agents, and achieve the effect of enhancing the usability of adhesive agents and improving the usability of masks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

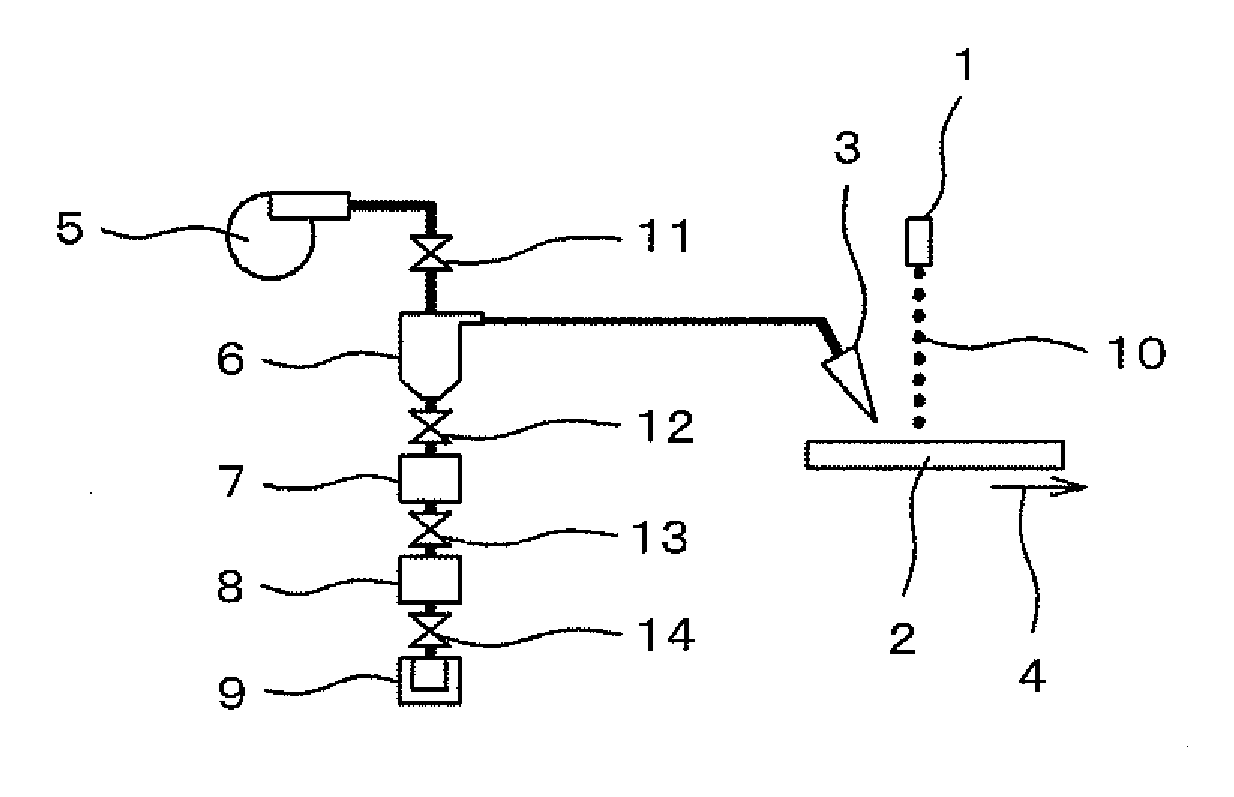

[0040]The present invention will be described referring to the drawings. FIG. 1 shows a basic structure of the present invention. A pulse laser 10 is irradiated from a laser irradiation window 1 to a deposition mask 2 as a target to be cleaned. The deposition mask 2 has been used for the deposition repeatedly, which needs to be cleaned. The frequency of the pulse laser is substantially long relative to the pulse width. The pulse laser is irradiated to the deposition mask 2 to be oscillated such that the deposition agent adhered to the deposition mask 2 is separated.

[0041]The deposition mask 2 moves along an advancing direction 4. The pulse laser 10 is controlled to scan vertically to the advancing direction 4. The advancement of the deposition mask 2 and the scan of the pulse laser 10 are combined so as to irradiate the pulse laser 10 to the entire surface of the deposition mask.

[0042]The deposition agent separated by the pulse laser is sucked by a suction nozzle 3 into a cyclone 6 tog

second embodiment

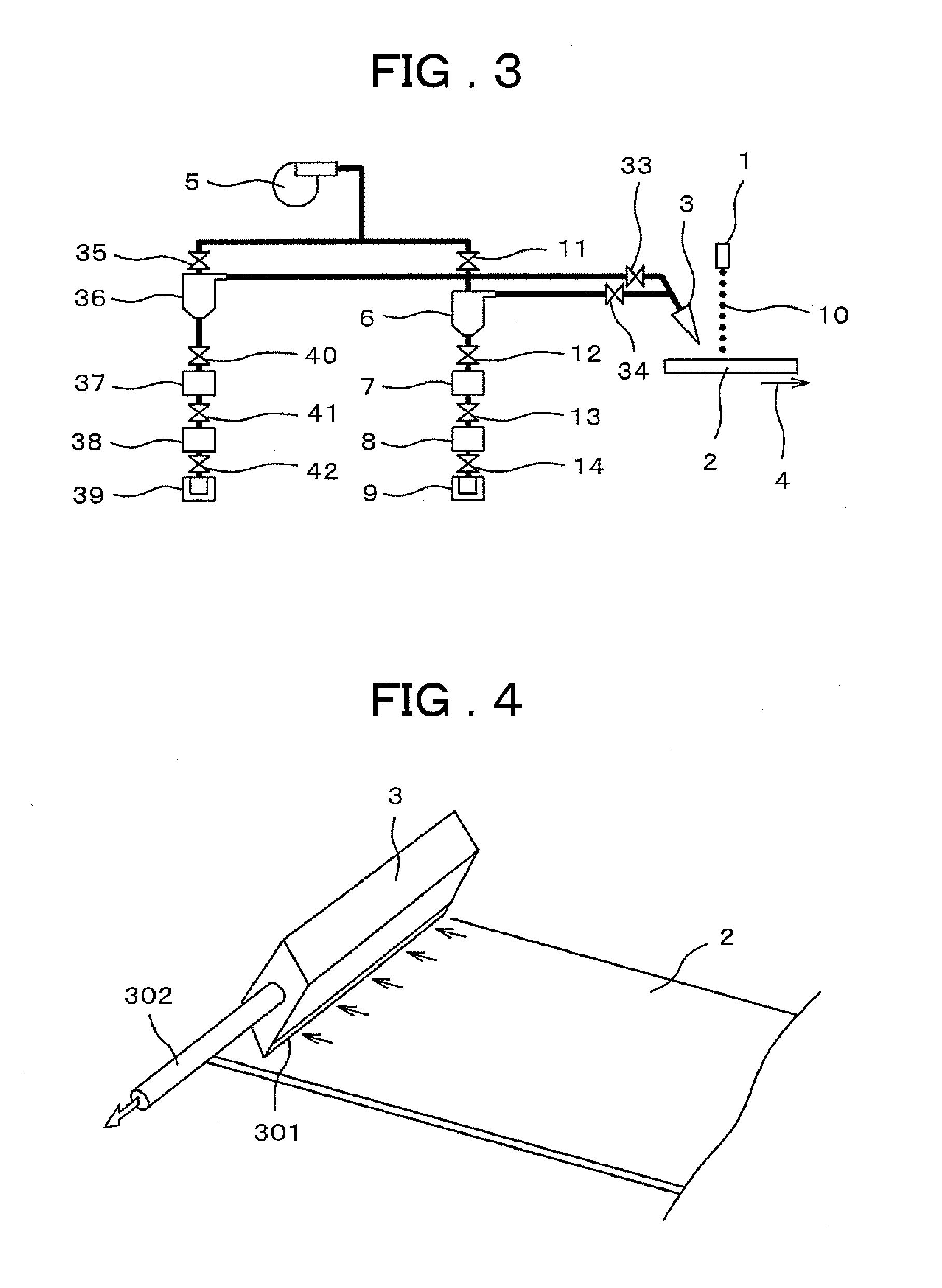

[0065]An example where two kinds of deposition masks 2, that is, the one subjected to 200-hour deposition using the deposition agent Alq3 (tris(8-quinolinolate)aluminum derivative), and the one subjected to 200-hour deposition using the deposition agent BeBq(bis(benzoquinolinolate)beryllium derivative) will be described hereinafter. FIG. 3 shows the structure of the device, which is formed by adding one more collection section to the basic structure shown in FIG. 1 to allow processing of two kinds of the deposition masks 2. The deposition mask 2 is cleaned using Alq3. The valves F34 and A11 are opened, and valves E33 and G35 are closed to activate the blower 5. The deposition mask 2 is transferred along the advancing direction 4 while irradiating the pulse laser 1. When the cleaning of the deposition mask 2 using Alq3 is finished, the valves F34 and A11 are closed, and the valves E33 and G35 are opened to process the deposition mask 2 using BeBq. The process for collecting the depositi

PUM

| Property | Measurement | Unit |

|---|---|---|

| Efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap